Safety

Information

Introduction

Product

Information

System

configuration

Mechanical

Installation

Electrical

Installation

Getting

Started

Basic

parameters

Running

the motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL Listing

Information

Unidrive SPM User Guide 133

Issue Number: 3 www.controltechniques.com

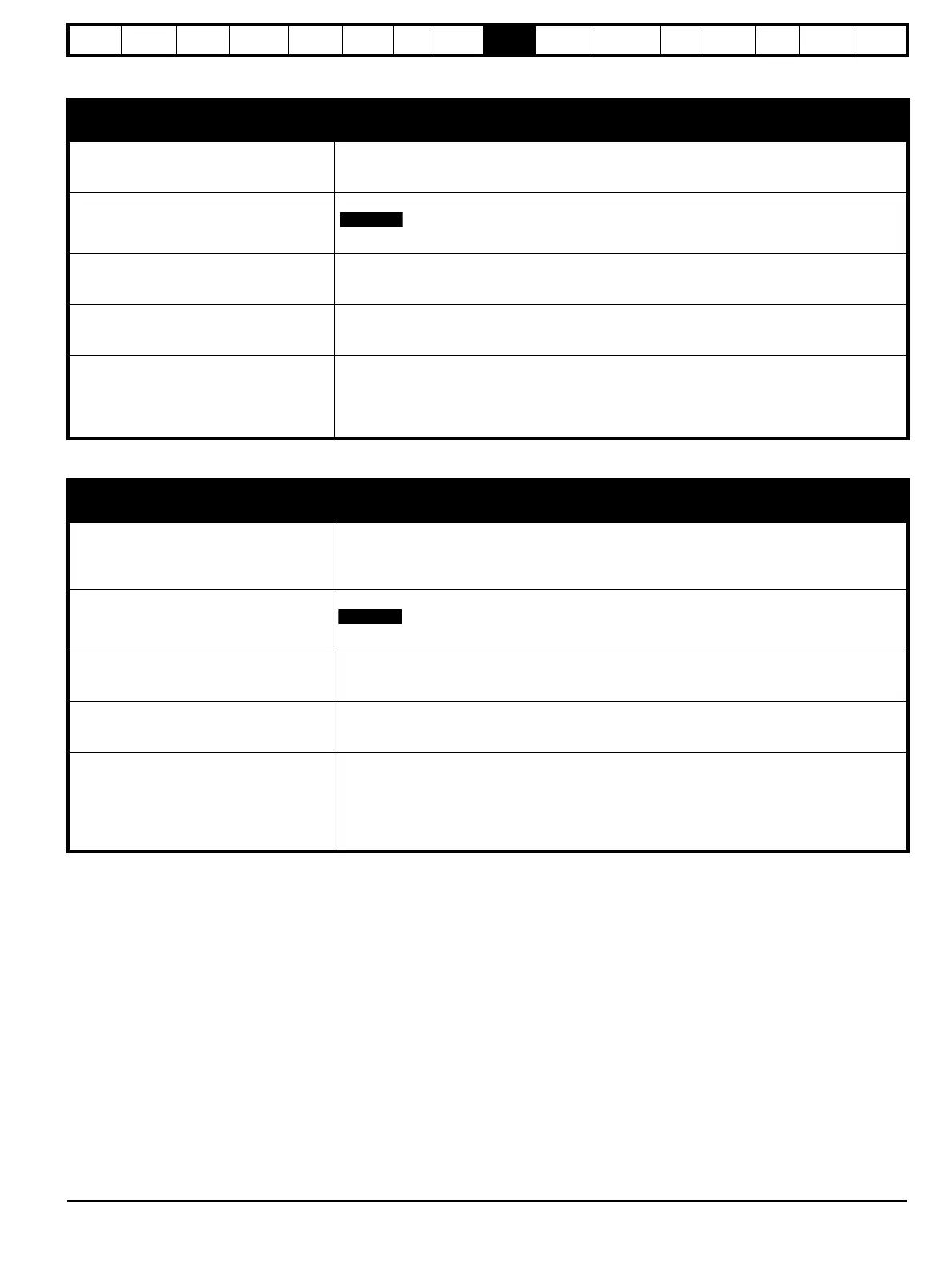

9.6.2 Detailed feedback device commissioning/start-up information

Standard quadrature encoder with or without commutation signals (A, B, Z or A, B, Z, U, V, W), or

Sincos encoder without serial communications

Encoder type Pr 3.38

Ab (0) for a quadrature encoder without commutation signals *

Ab.SErVO (3) for a quadrature encoder with commutation signals

SC (6) for a Sincos encoder without serial communications *

Encoder power supply voltage Pr 3.36

5V (0), 8V (1) or 15V (2)

If output voltage from the encoder is >5V, then the termination resistors must be disabled Pr

3.39

to 0

Encoder number of lines per

revolution

Pr 3.34

Set to the number of lines or sine waves per revolution of the encoder.

See section 9.6.3 Restriction of encoder number of lines per revolution on page 135 for restrictions

on this parameter.

Encoder termination selection

(Ab or Ab.SErVO only)

Pr 3.39

0 = A, B, Z termination resistors disabled

1 = A, B termination resistors enabled and Z termination resistors disabled

2 = A, B, Z termination resistors enabled

Encoder error detection level Pr 3.40

0 = Error detection disable

1 = Wire break detection on A, B and Z inputs enabled

2 = Phase error detection (Ab.SErVO only)

3 = Wire break detection on A, B and Z inputs and phase error detection (Ab.SErVO only)

Termination resistors must be enabled for wire break detection to operate

* These settings should only be used in closed loop vector mode, otherwise a phase offset test must be performed after every power up.

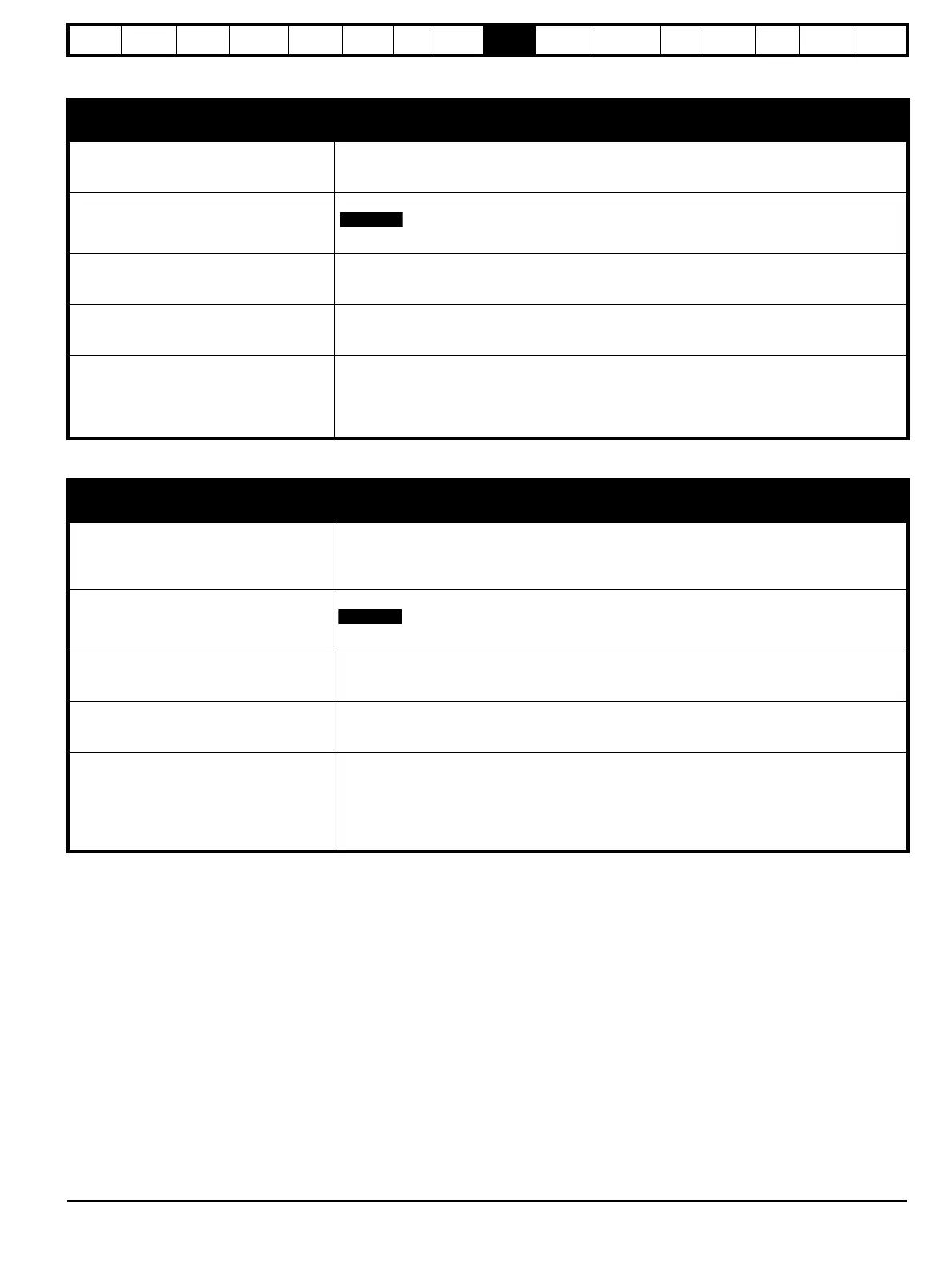

Incremental encoder with frequency and direction (F and D), or

Forward and Reverse (CW and CCW) signals, with or without commutation signals

Encoder type Pr 3.38

Fd (1) for frequency and direction signals without commutation signals *

Fr (2) for forward and reverse signals without commutation signals *

Fd.SErVO (4) for a frequency and direction encoder with commutation signals

Fr.SErVO (5) for forward and reverse signals with commutation signals

Encoder power supply voltage Pr 3.36

5V (0), 8V (1) or 15V (2)

If output voltage from the encoder is >5V, then the termination resistors must be disabled Pr

3.39

to 0

Encoder number of lines per

revolution

Pr 3.34

Set to the number of pulses per revolution of the encoder divide by 2.

See section 9.6.3 Restriction of encoder number of lines per revolution on page 135 for restrictions

on this parameter.

Encoder termination selection Pr 3.39

0 = F or CW, D or CCW, Z termination resistors disabled

1 = F or CW, D or CCW termination resistors enabled and Z termination resistors disabled

2 = For CW, D or CCW, Z termination resistors enabled

Encoder error detection level Pr 3.40

0 = Error detection disable

1 = Wire break detection on F & D or CW & CCW, and Z inputs enabled

2 = Phase error detection (Fd.SErVO and Fr.SErVO only)

3 = Wire break detection on F & D or CW & CCW, and Z inputs and Phase error detection

(Fd.SErVO and Fr.SErVO only)

Termination resistors must be enabled for wire break detection to operate

* These settings should only be used in closed loop vector mode, otherwise a phase offset test must be performed after every power up.

Loading...

Loading...