SS2100i-1 Gas Analyzer

B–12 4900002224 rev. E 12-18-20

9. Carefully replace the mirror assembly onto the cell in the same

orientation as previously marked.

10. Tighten the 4 socket-head cap screws evenly with a torque wrench

to 30 in-lbs (28 m or 8 m measurement cell) or 13 in-lbs (0.1 m or

0.8 m measurement cell).

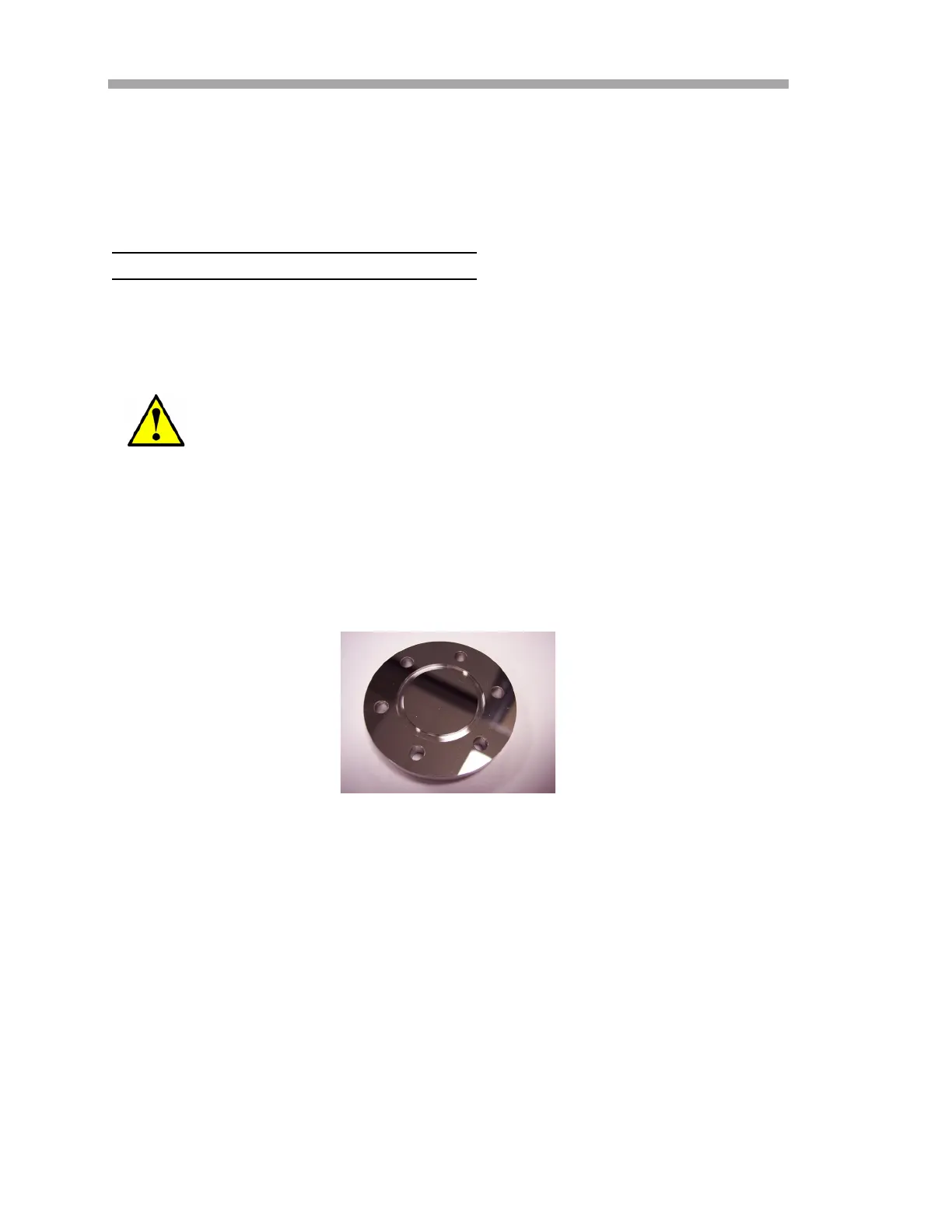

Toreplacethestainlesssteelmirror

If your system has been configured with a stainless steel mirror in the 0.1 m

or 0.8 m measurement cell, use the following instructions for replacing the

mirror.

1. After the mirror has been removed (refer to “To remove the

mirror assembly (0.8 m/0.1 m)” on page B-10), confirm the

need to replace mirror due to contamination. If yes, set mirror aside.

2. Put on clean acetone-impenetrable gloves.

3. Obtain the new stainless steel mirror. Refer to Figure B–6 below.

4. Check the O-ring.

a. If a new O-ring is needed, apply grease on fingertips and then

to the new O-ring.

b. Place newly greased O-ring into the groove around the outside

of the mirror taking care not to touch the mirror surface.

5. Carefully place the new stainless steel mirror onto the cell making

sure the O-ring is properly seated.

6. Tighten the socket-head cap screws evenly with a torque wrench to

13 in-lbs.

If stainless steel mirrors are replacing another version of mirror in

the field, such as glass, the analyzer may need to be returned to

the factory for re-calibration to ensure optimal cell function. Refer

to “Service Contact” on page B-27.

Figure B–6 Stainless steel

mirror; mirror side up

Loading...

Loading...