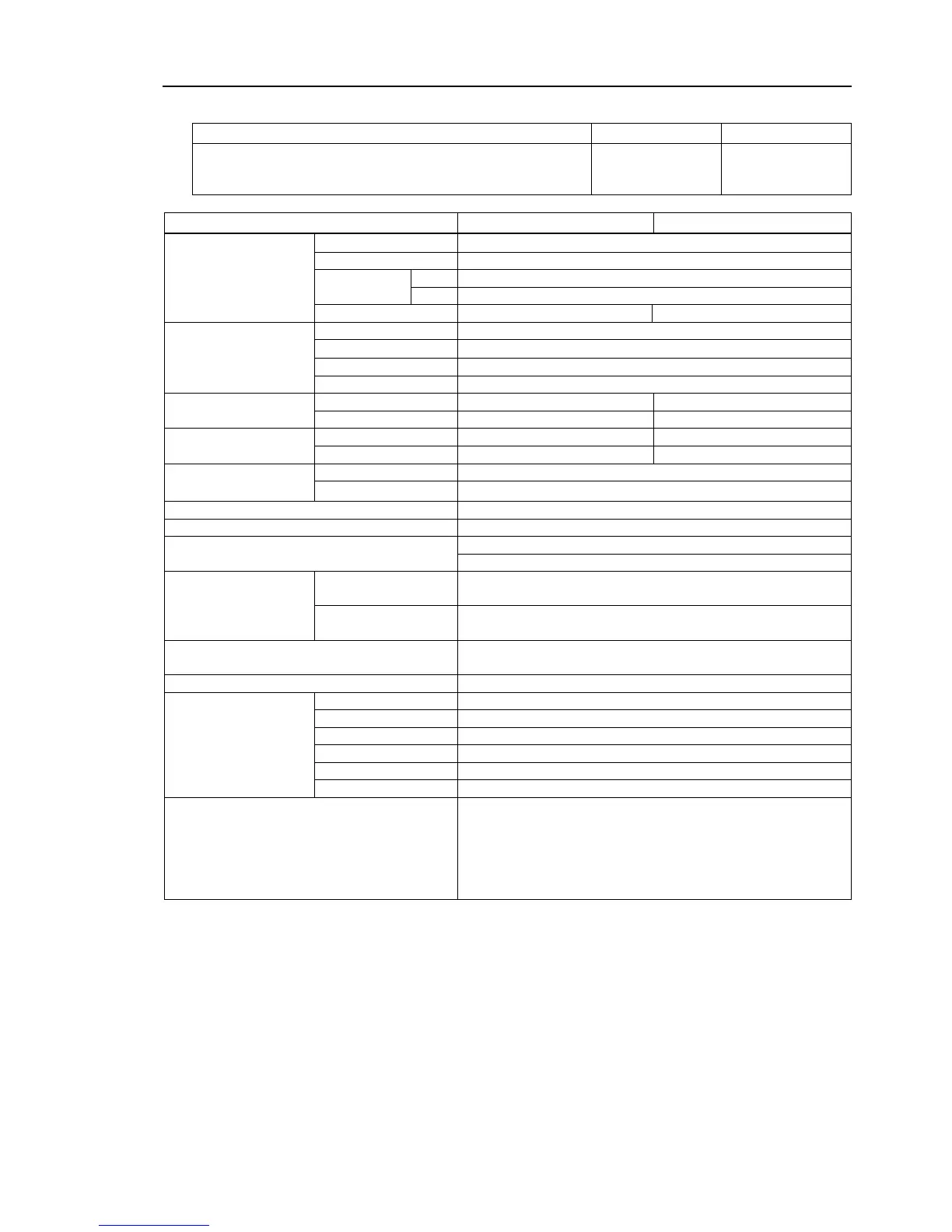

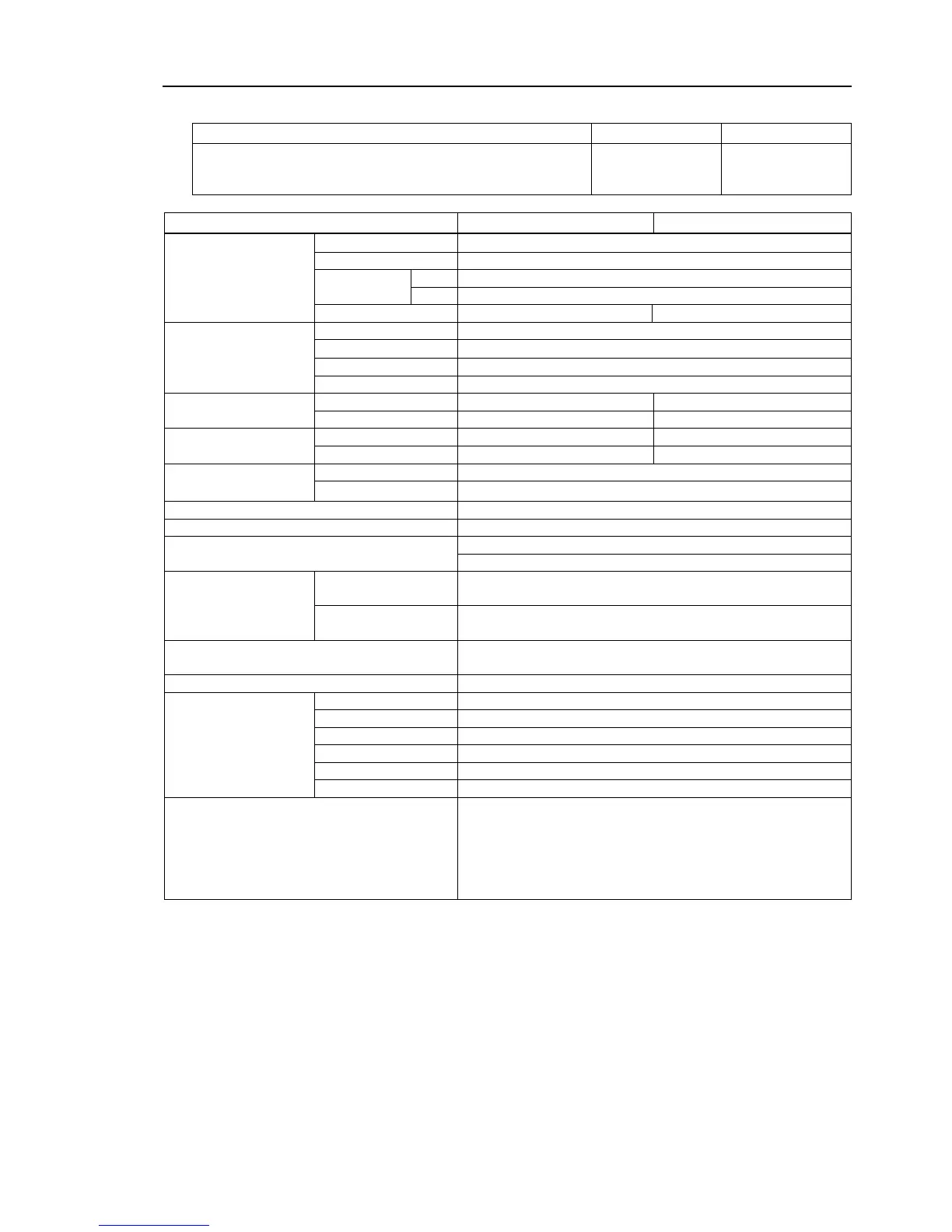

Setup & Operation 2. Specifications

G10 / G20 Rev.20 39

*a : The Joint #2 values for the following manipulators

G10/G20-85C, P, D with bellows option (Z: -360 to -390 only)

G10/G20-85CW, PW, DW with bellows option

G10/G20-85CR, PR, DR with bellows option

Joint #4 allowable

moment of inertia *4

Installed wire for customer use

24 (15 pin + 9 pin : D-sub)

Installed pneumatic

tube for customer use

2 pneumatic tubes (ø6 mm) : 0.59 MPa (6 kgf/cm

2

: 86 psi)

2 pneumatic tubes (ø4 mm) : 0.59 MPa (6 kgf/cm

2

: 86 psi)

Environmental

requirements

5 to 40°C (with minimum temperature variation)

Ambient relative

humidity

10 to 80% (no condensation)

Equivalent continuous A-weighted sound

pressure level *5

Assignable Value

( ) Default values

0,400 to (10,400) to 20,400

Safety standard

CE Marking : EMC Directive, Machinery Directive,

RoHS Directive

KC Marking / KCs Marking

UL standards (In case of UL specification):

UL1740, ANSI/RIA R15.06, NFPA 79

*1: The exhaust system in the Cleanroom-model Manipulator (G10/G20-*

**C*) draws air from the base

interior and arm cover interior.

A crack or other opening in the base unit can cause loss of negative air pressure in the outer part of the

arm, which can cause increased dust emission.

Do not remove the maintenance cover on the front of the base.

Seal the exhaust port and the exhaust tube with vinyl tape so that the joint is airtight.

If the exhaust flow is not sufficient, dust particle emission may exceed the specified maximum level.

Loading...

Loading...