Appendix B-2 Maintenance Rev. A

Confidential

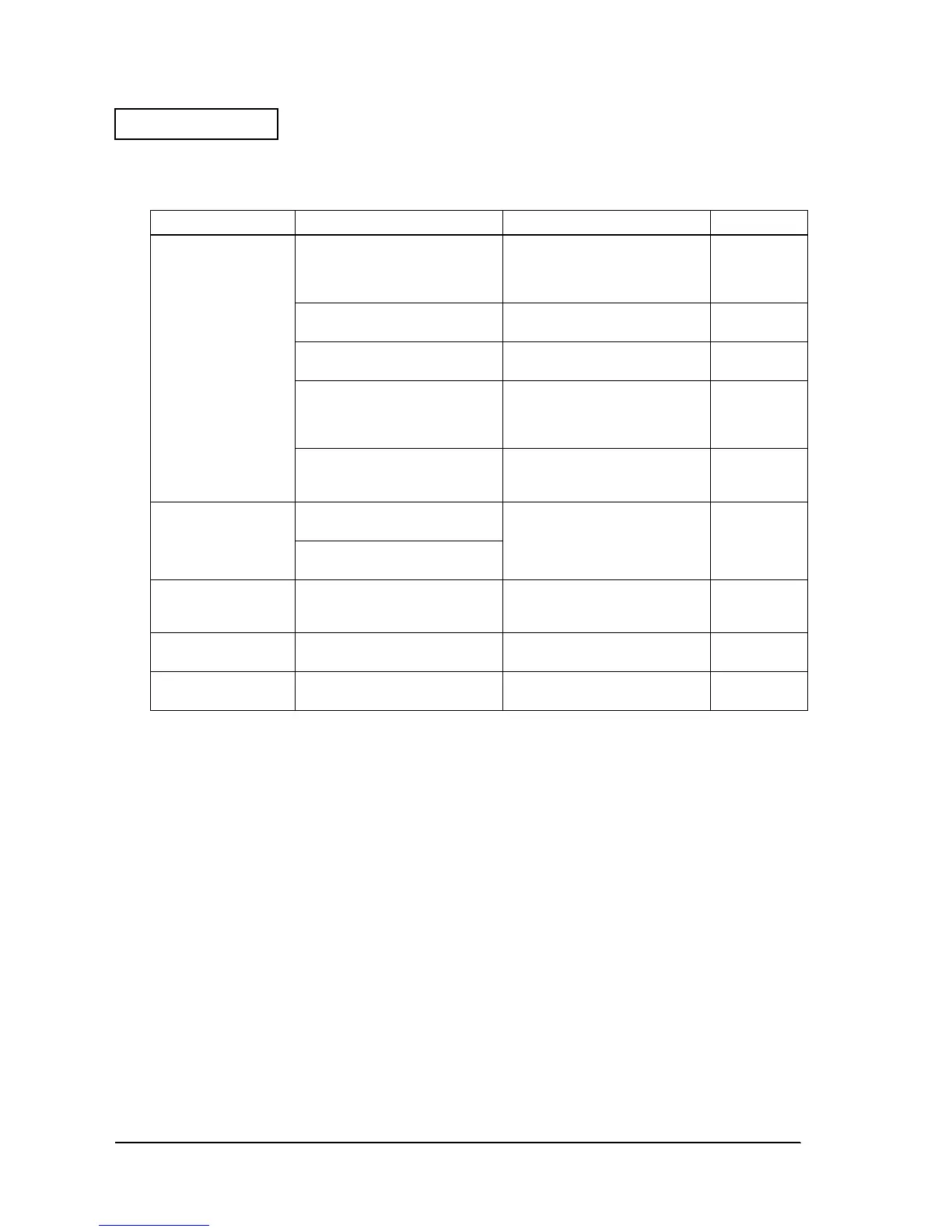

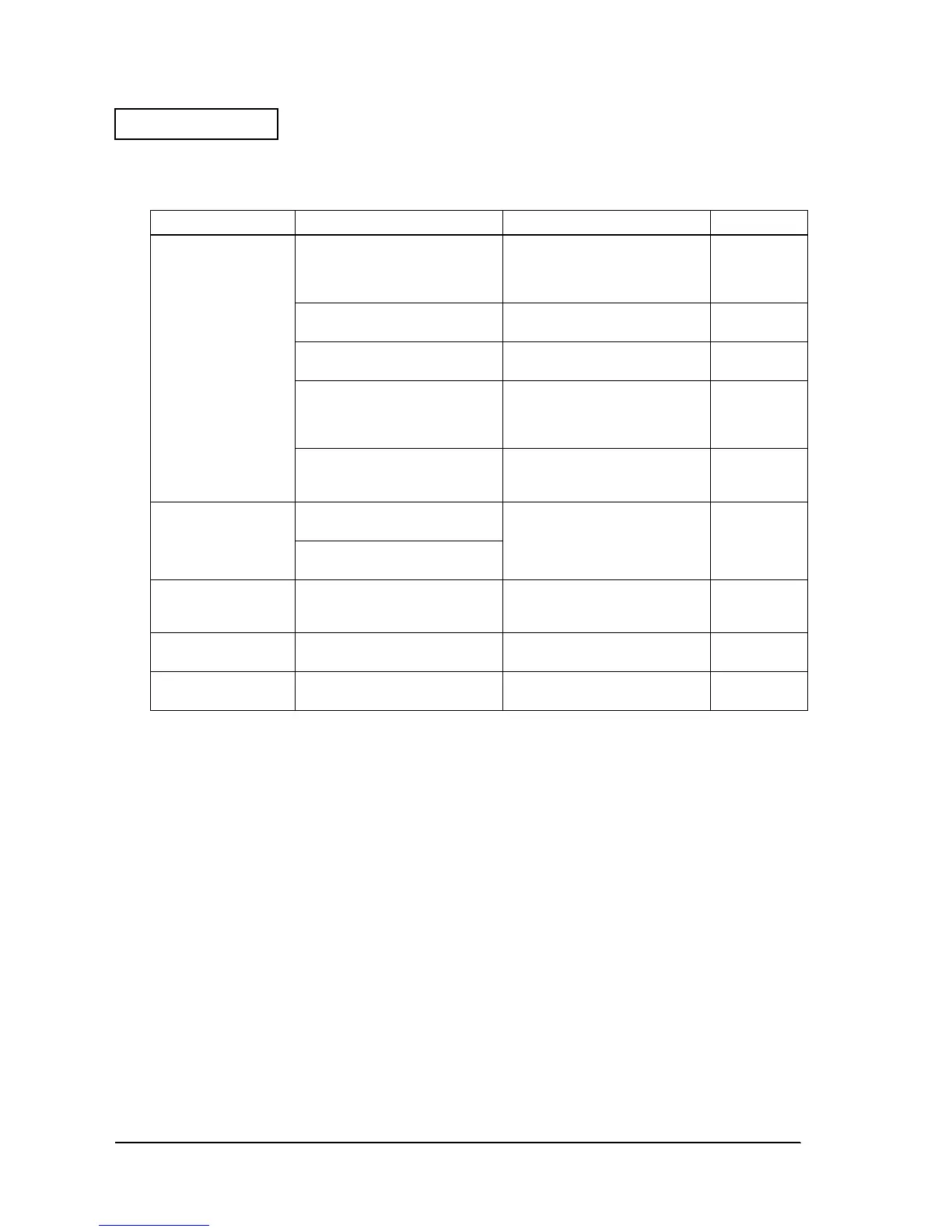

Periodic Inspection

Table B-2 Periodic inspection checklist

Items to Check Checkpoints Handling

When to Perform

Status of paper dust,

dirt, dust adhering to

the parts

Is there any uneven or faint

printing?

(1)Clean the thermal head (see

page B-3 for instructions).

(2)Clean the receipt side platen

roller.

Every three

month

Is there a great deal of dirt, or dust

adhering to the parts?

Use an electric vacuum cleaner to

clean thoroughly.

Biannually

Is there paper dust in the top of

form detector or paper slip path?

Use an air spray can to blow out

paper dust from the paper path.

Biannually

Is there any paper dust or other

foreign matter adhering to the

paper end detector or the

ejection detector?

Wipe with a soft cloth to remove

the paper dust, etc.

Biannually

Is the receipt side platen roller

white with paper dust?

Dampen a cloth with a small

amount of water and wipe the

roller surface.

Biannually

Spring Shapes Is the fixed blade holder spring

deformed or loose?

Attach or replace the springs.

Are the other springs deformed or

loose?

Autocutter Status Is there paper dust or foreign

matter adhering to the cutter

blade?

Remove the paper dust or foreign

matter from the cutter blade.

Biannually

Lubrication Status Check the lubrication. See “General Lubrication

Drawings” to lubricate.

Biannually

Operation Check Are there any abnormal noises or

printing errors when operating?

See “Troubleshooting.” Biannually

Loading...

Loading...