Preventive Maintenance

Fox Maintenance © Essemtec AG 4-33

0000074/05

/ March 31, 2017

Noise Test

Check for any vibrations on the head or any squeak or scraping noises.

Check also the smooth turning of the theta element

In case of squeak and scraping noises or if there is a noticeable resistance of the theta element, it is

recommended to do the yearly maintenance, described on page 4-50.

Maintain ZT Element (Z linear axis / Theta rotation axis)

Clean and lubricate the spindle.

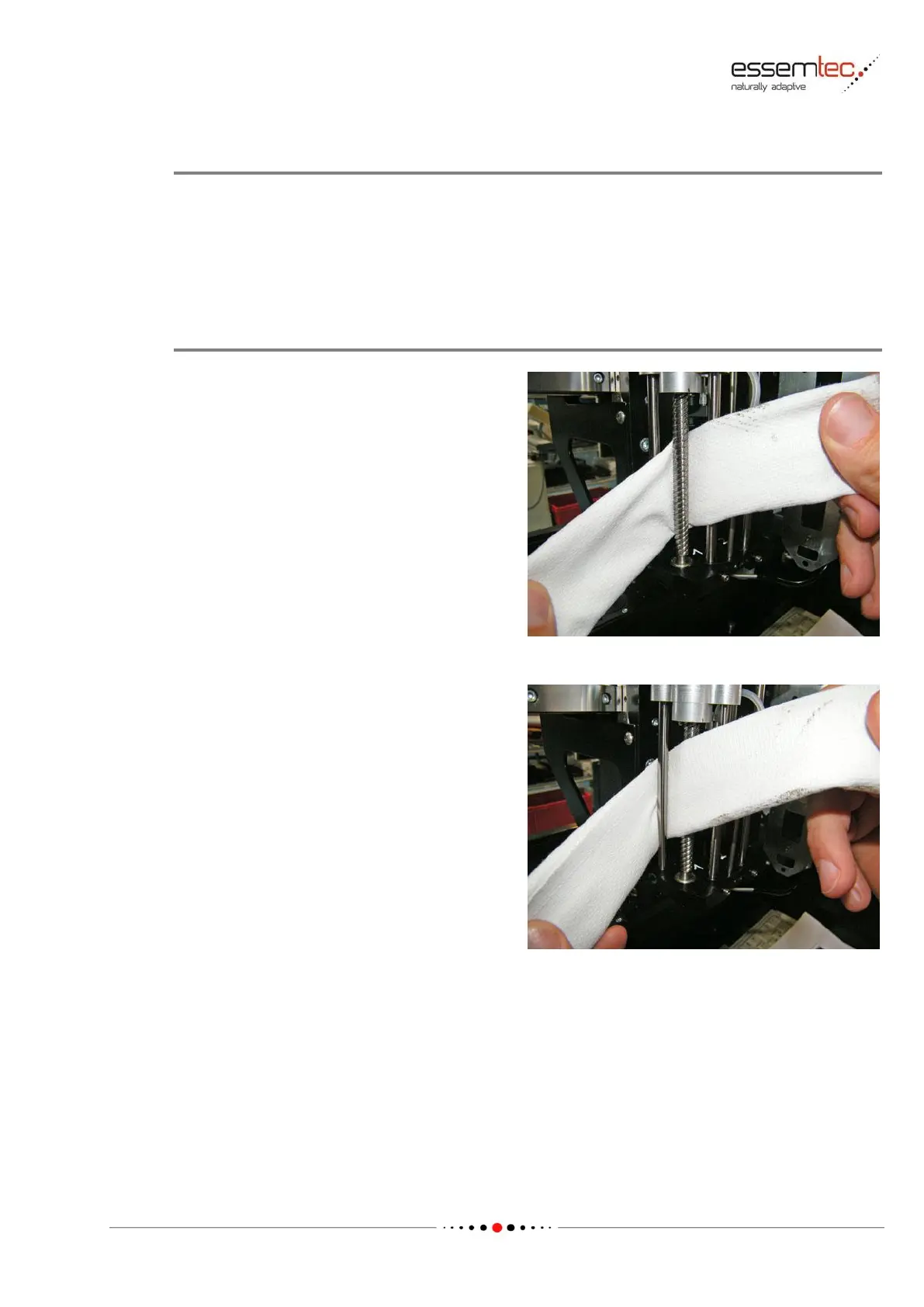

Using a soft and lint-free cloth, wipe off the dirty

grease. Afterwards lightly dampen a soft and

lint-free cloth with IPA Isopropyl alcohol and

wipe all spindles of the head as indicated in the

picture.

Lubricate the spindles slightly with Essemtec

P&P Head Grease (SP26/HG01) by means of a

brush (anytime keep the brush clean, free of

dust and metal powders). Do not apply too

much grease. Move manually the the Z-axis up

and down to apply evenly the grease. Wipe off

any excess.

Clean and lubricate guide shaft.

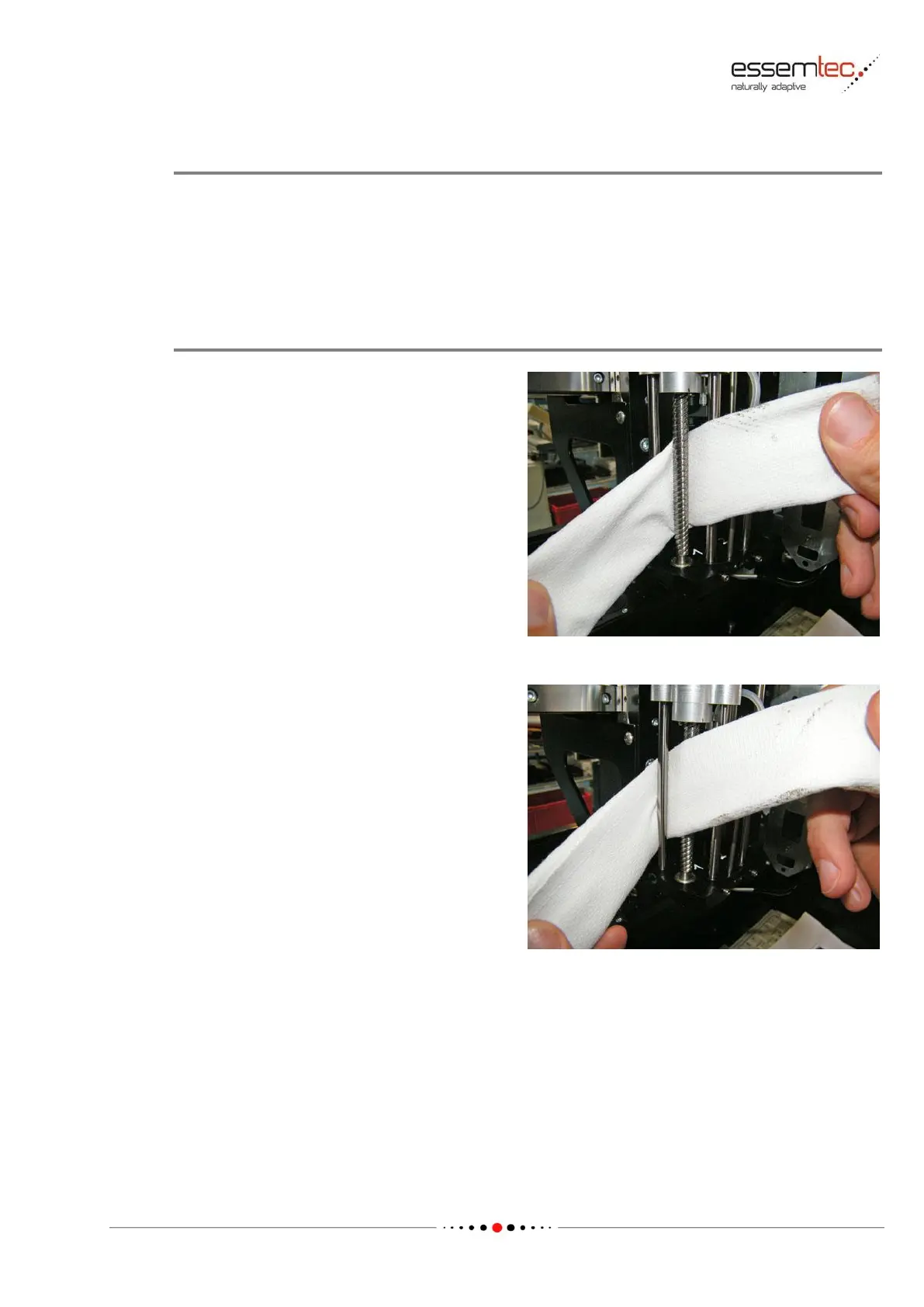

Using a soft and lint-free cloth, lightly dampened

with IPA Isopropyl alcohol, wipe all guide shafts

of the head as indicated in the picture.

Lubricate the guide shafts slightly with Essemtec

P&P Head Grease (SP26/HG01) by means of a

brush (anytime keep the brush clean, free of

dust and metal powders). Do not apply too

much grease. Move manually the the Z-axis up

and down to apply evenly the grease. Wipe off

any excess.

Loading...

Loading...