KT5500 5-

1

/

2

” Tong & CLInCHER® BaCKup

SECTIon ConTEnTS

7.14

TECHnICaL ManuaL

HyDRauLIC MoToR InfoRMaTIon

WARNING: RINEER RECOMMENDS FOLLOWING ALL STANDARD SHOP SAFETY PRACTICES SPECIFICALLY INCLUDING WEARING OF EYE PROTECTION.

33

34

35

36

B

A

9

1) Install dowel pins into

rotor/stator cartridge.

2) Pour a small amount of

clean oil into the cartridge.

3) Install front housing onto

rotor/stator cartridge.

4) Make sure alignment

marks are lined up.

1) Install 5/8-11 bolts.

2) Torque bolts to 50 ft./lbs.

1) Rotate shaft in both

directions to assure that the

shaft turns smoothly.

2) Torque motor to 190 ft./lbs.

3) Rotate shaft again in both

direc

tions to assure that the

s

haft turns smoothly.

NOTE: Spool should be

oriented as shown for two

speed motors with model

codes 62, 63, 68, & 69.

NOTE: Slight design

variations may exist in

motors manufactured

either before or after the

printing of this manual.

SPOOL ASSEMBLY FOR THE

TWO SPEED MOTOR

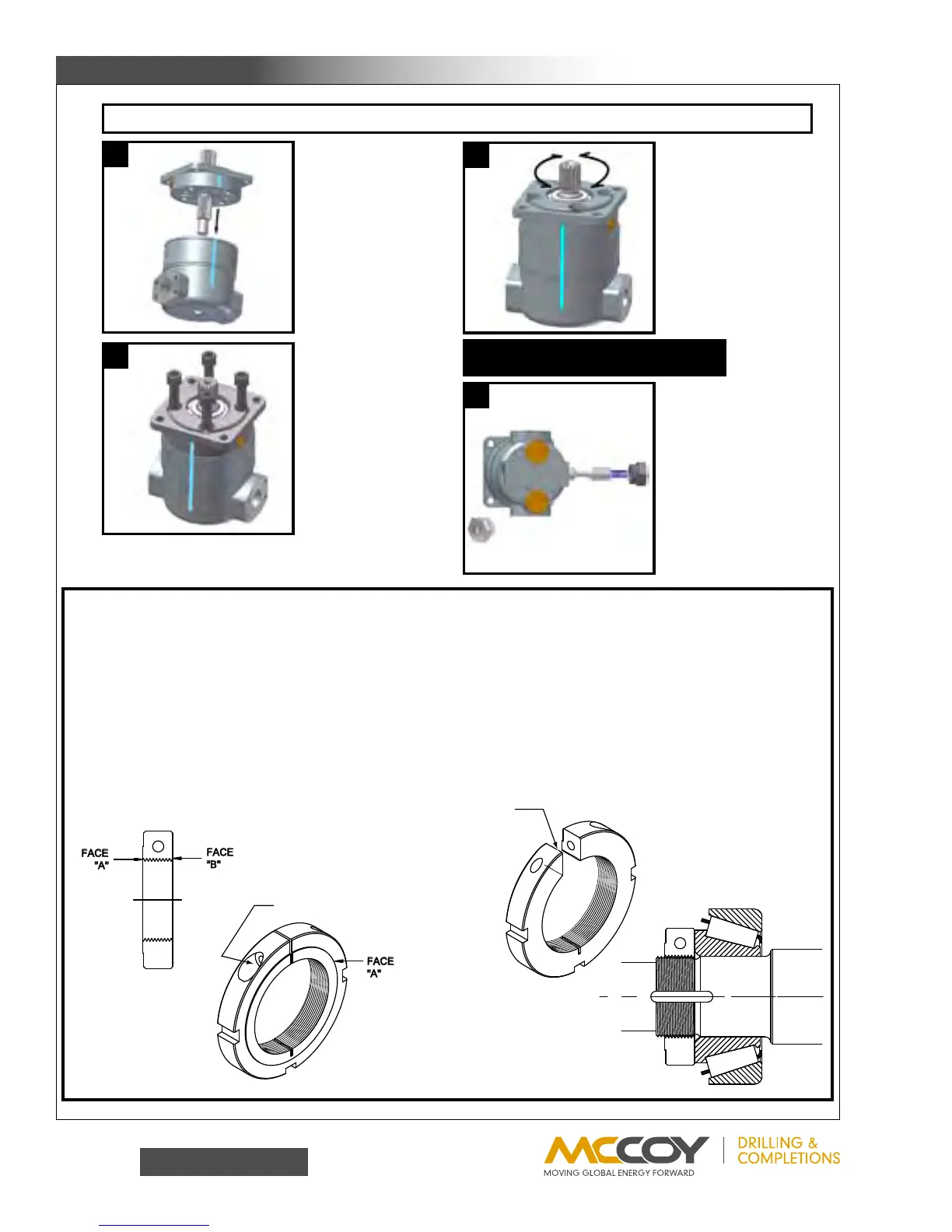

1)� Clean ALL assembly parts w/ lacquer thinner.

2)� Dip clampnut and clamping bolt separately in lacquer thinner.

� (Steps 3 thru 10 must be conducted to completion ONE assembly at a time.)

3)� Press bearing cups into bearing housing. Make sure they are pressed completely against bearing shoulders.

4)� Coat inner race of large cone with #609 (green) Loctite and press cone onto the shaft. Make sure the cone is completely against the shoulder of the shaft.

5

)� Insert shaft and large cone into bearing housing.

6)� Coat inner race of small cone with #609 (green) Loctite and press small cone onto shaft.

7)� Apply #272 (red) Loctite to the clampnut threads of the shaft. Apply #242 (blue) Loctite to the threads of the clamping bolt and install in the clampnut.

8)� Spin clampnut onto shaft with the "B" face towards bearings. After the nut threads are fully engaged, but prior to the nut contacting the bearings, �

� tighten the clamping bolt until there is drag on the clamping nut (see note Fig. 1). Tighten the nut until a 20 to 30 inch pound rolling torque is achieved.

9)� Tighten clamping bolt on clampnut to 70 inch pounds and recheck rolling torque. Apply inspectors lacquer to head of the bolt.

10)� Allow a minimum of 24 hrs. to dry.

Figure 1

CUTAWAY

Note:

The slit in the clampnut

allows for loose

assembly on the shaft.

Once in position, the

clampnut clamping bolt

MUST be tightened to

a slight drag in order to

correctly engage the

threads on the shaft to

achieve the clamp

force required.

CLAMPING BOLT

WHEEL MOTOR SHAFT AND BEARING ASSEMBLY PROCEDURE

Loading...

Loading...