KT5500 5-

1

/

2

” Tong & CLInCHER® BaCKup

SECTIon ConTEnTS

2.3

TECHnICaL ManuaL

SETup & opERaTIon

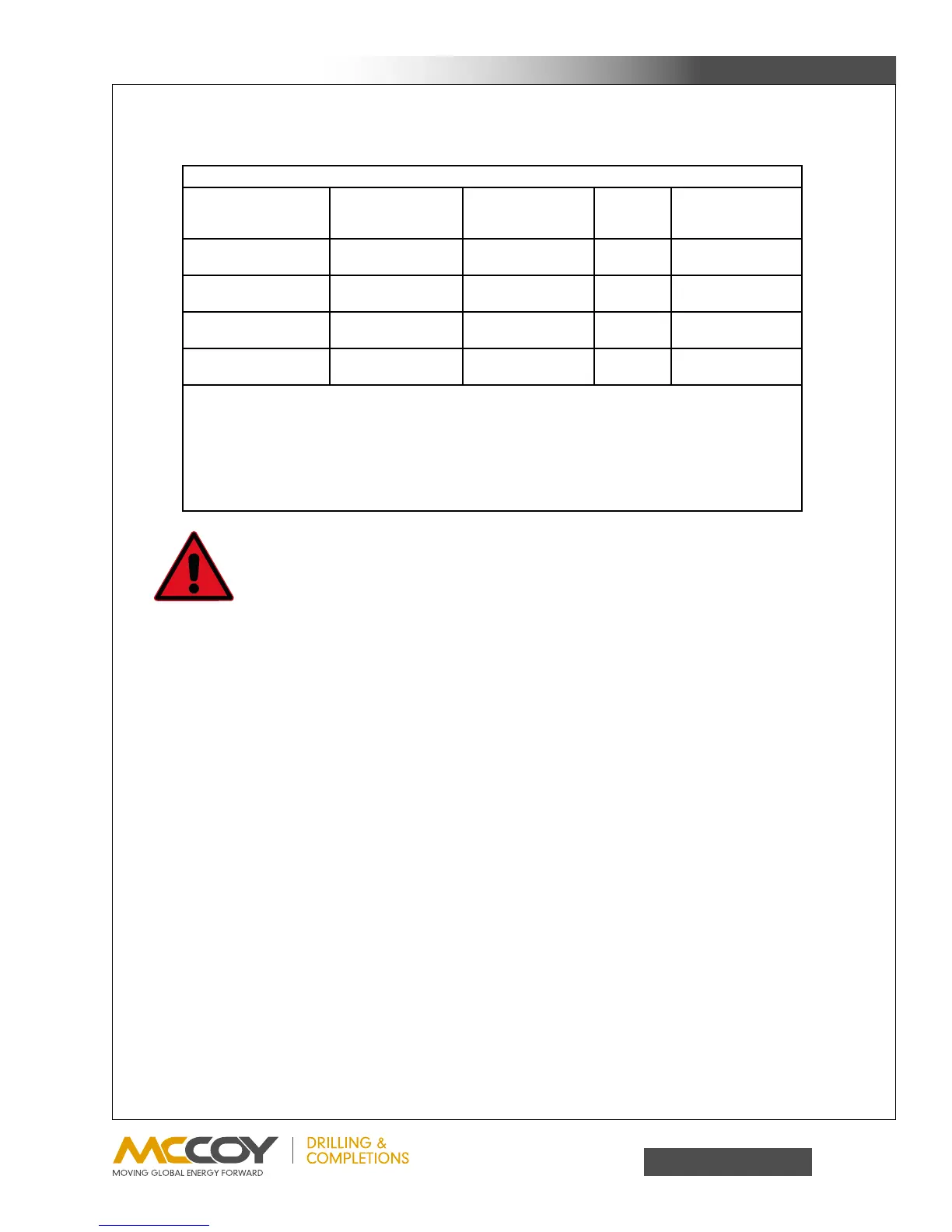

UnitsdesignedandmanufacturedinaccordancewithEN12079andDNV2.7-1shouldbetestedandexaminedinaccordance

withthefollowingscheduleofexaminationandtest.Theuseroftheload-bearingdeviceshallplaceapermanentplacardorplate

uponwhichthetypeanddateofthelasttestshallberecorded.Toavoidconfusion,theplateshallnotcarrythedateofthenext

testorexamination,onlythemostrecent.

Test / Examination

Time / inTerval lifTing TesTs

1

non-DesTrucTive

examinaTion (nDe)

of lifTing PoinTs

Thorough

visual

examinaTion

suffix To Be markeD

on PlaTe aTTacheD

To uniT

InitialCertificationBy

Farr/Superior

YES YES YES T

IntervalNotExceeding

12Months

Atthediscretionof

inspectionbody

Atthediscretionof

inspectionbody

YES TorVN

3

IntervalNotExceeding

60Months

Atthediscretionof

inspectionbody

YES YES TorVN

FollowingSubstantial

RepairorAlteration

YES YES YES T

1.LiftingtestasperS7.3BSEN12079orDNV2.7-1May1995

2.T=ProofTest,non-destructiveexamination;VN=nondestructiveexaminationandvisualexamination;

V=visualexamination.

3.Dependantuponwhethernon-destructiveexaminationhasbeencarriedout.

4.Forthepurposesofthisstandard,asubstantialrepairormodificationisdefinedasanyrepairand/or

modificationthathasbeencarriedoutwhichmay,intheopinionoftheinspectionbody,affecttheload-

bearingelementsofthecontainerorliftingdevice,orelementsthatcontributedirectlytoitsstructural

integrity.

IF MECHANICAL DAMAGE IS SEEN OR SUSPECTED ON A LOAD-BEARING

DEVICE, OR IF THE LOAD-BEARING DEVICE HAS BEEN OVERLOADED, IT MUST

BE REMOVED FROM SERVICE AND QUARANTINED UNTIL RECERTIFIED

Writtenrecordsofthemostrecentperiodicinspectionshallbemaintained,andshallincludetheconditionofthesling.

2. Proper Use Of Load-Bearing Devices

Wheneveranyload-bearingdeviceisused,thefollowingpracticesshallbeobserved.

• Load-bearingdevicesthataredamagedordefectiveshallnotbeused.

• Slingsshallnotbeshortenedwithknotsorboltsorothermakeshiftdevices.

• Slinglegsshallnotbekinked.

• Load-bearingdevicesshallnotbeloadedinexcessoftheirratedcapacities.

• Slingsshallbesecurelyattachedtotheirload.

• Load-bearingdevicesshallbeprotectedfromsnagging,andshallnotbefurtherobstructedbyanyobject.

• Suspendedloadsshallbekeptclearofallobstruction.

• Allemployeesshallbekeptclearofloadsabouttobeliftedandofsuspendedloads.

• Handsorfingersshallnotbeplacedbetweentheslinganditsloadwhiletheslingisbeingtightenedaroundtheload.

• Shockloadingisprohibited.

• Donotstanddirectlyunderaloadduringlifting.

3. Storage Of Load-Bearing Devices

Properstorage ofout-of-service loadbearing devicesis importantto ensurefull integrityof thedevice onceit isreturned to

service.Farrrecommendsobservingthefollowingpractices.

• Wipeoffallexcessgrease.Useasolvent-basedcleaneronragstowipeallexternalsurfacestoremoveresidualgrease

orhydraulicfluid.Oncetheoutsidesurfaceshavebeende-greased,wipeallexternalsurfaceswithcleanwatertoremove

residualsolvent.

• Farrrecommendsthatananti-corrosiveagentsuchasTectyl

®

506beappliedtoallexternalsurfaces.Refertomanufac-

turerdatasheetsforproperapplicationandsafetyinformation.Allowtheanti-corrosivecoatingampletimetodry-referto

manufacturerdatasheetsfordryingtimesatroomtemperature.

• Storeinaclean,drylocation.Whenreturningtoservice,notethatafullinspectionofthedevicemustbeperformed.

Loading...

Loading...