KT5500 5-

1

/

2

” Tong & CLInCHER® BaCKup

SECTIon ConTEnTS

2.23

TECHnICaL ManuaL

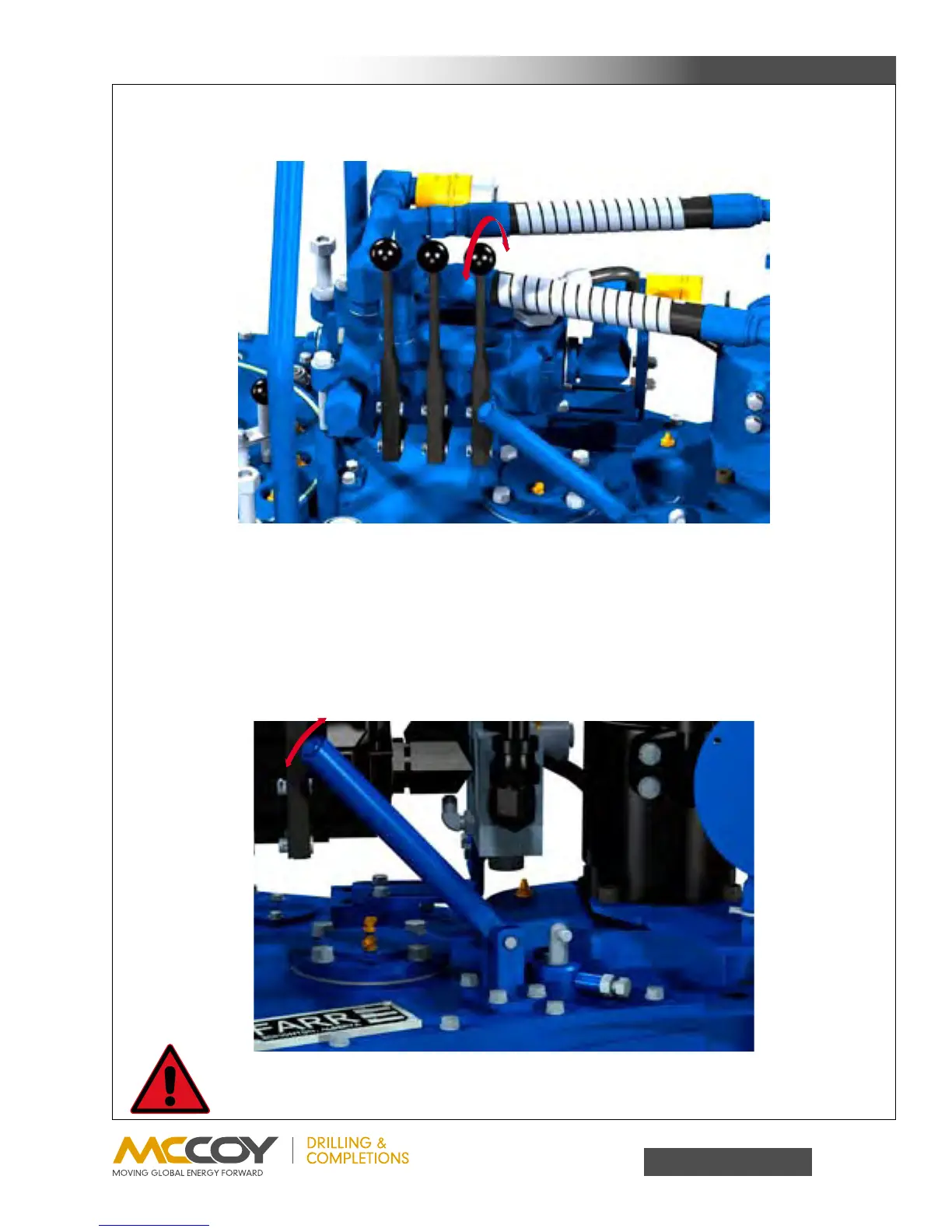

LIFT CYLINDER

Thisisadirect-actingvalve.Pushingthevalvehandleforwardwillcausetheliftcylindertoliftthetongvertically.Pullingthe

valvehandleintheoppositedirectionwillcausetheliftcylindertolowerthetong.

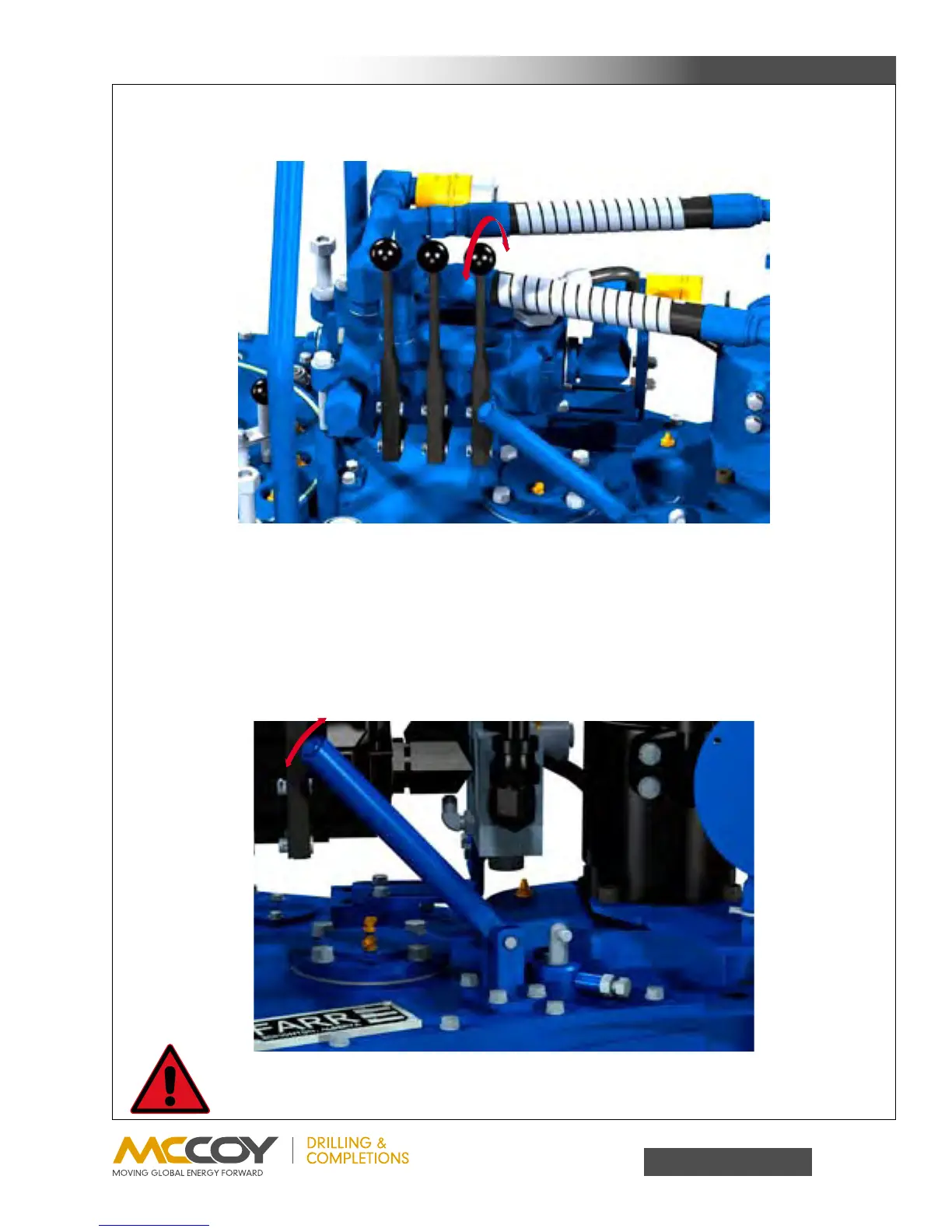

3. SHIFTING GEARS

Theshiftingshafthasthree“detent”positionsidentifyingthelowspeed/hightorqueposition,the“neutral”orfree-spinningposi-

tion,andthehighspeed/lowtorqueposition.Thedetentstrengthmaybeadjustedbyreleasingthelocknutonthedetenttube

andincreasingorrelaxingpressureonthedetentspring.Ensurethelocknutistightenedoncethedesireddetentpressurehas

beenset.

Toshifttothe high-speed gear,movetheshiftinghandle upwardfromneutralposition.To shifttothelow-speedgear, move

theshiftinghandledownthroughtheneutraldetenttoitslowestposition.Notethatthehighclutchgearorthelowclutchgear

maynotbeexactlyalignedwhenshifting,sotheoperatormayneedto“bump”themotorcontrolhandleslightlytoturnthemain

clutchgearshaftandshiftingcollarintoalignment.Thisismosteffectivewhenapplyingasmallamountofpressureonthegear

shiftleverinthedirectionyouwanttoshiftthetong,ensuringtheshiftingcollarwill“catch”whenthemainclutchgearaligns

witheitherthehighorlowclutchgear.

SETup & opERaTIon

SHIFTING TONG WHILE ROTATING THE MOTOR AND CAGE PLATE MAY RESULT IN CATASTROPHIC

GEAR TRAIN FAILURE

Loading...

Loading...