DAD 143.x User Manual Profinet Rev.1.1.1 March 2023 Page 31 of 95

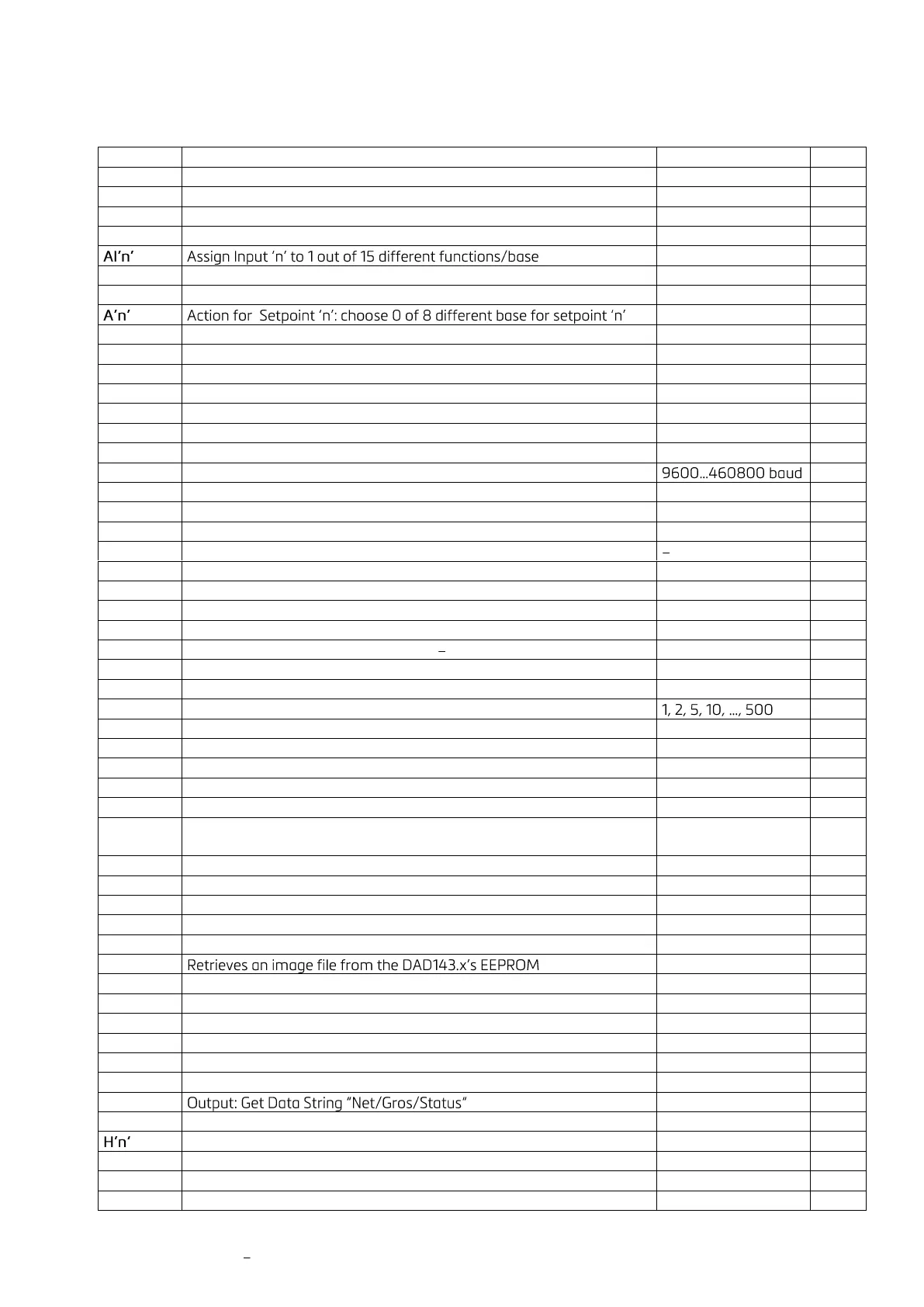

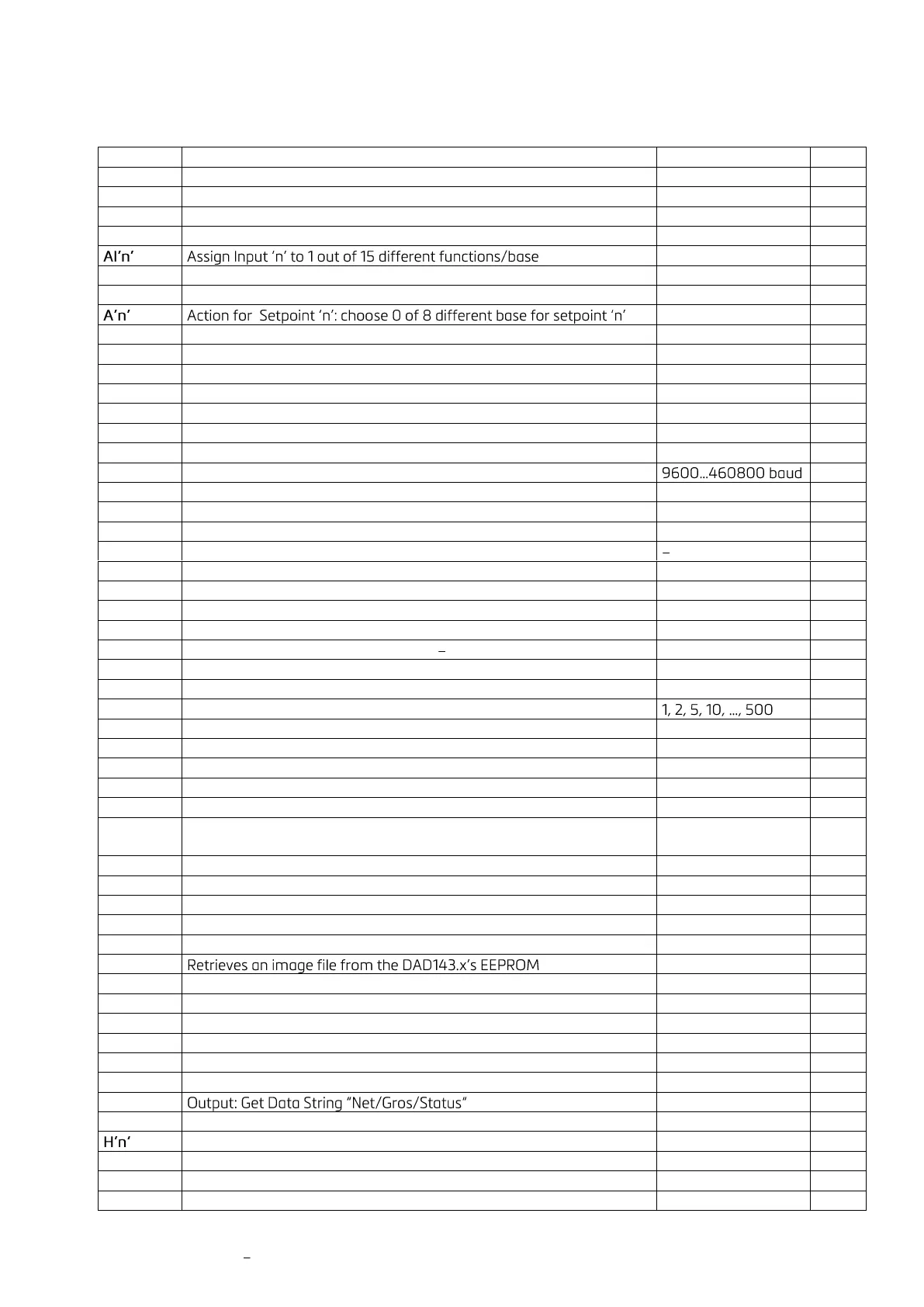

8 Setup via PC / PLC - Command Overview -

Get/set analog output action (base)

Communication: Device Address

Absolute gain calibration

Analog Output Mode Current / Voltage

Reference value for analog output

Ethernet address assignment method

Save analog output parameters

Auto transmit after Power ON

Show the actual internal mV/V value

Absolute zero point calibration

Calibration: Open Calibration Sequence; Read TAC Counter

Calibration: Set Calibration Gain (Span) at Load > Zero

Calibration: Minimum Output Value

Communication: Close Device

Calibration: Set Maximum Output Value (n = 1, 2 or 3)

Save the Calibration Data (CM, CI, DS, DP, etc.) to the EEPROM

Calibration: Set Calibration Zero Point Scale Without Load

Calibration: Set Decimal Point Position

Calibration: Set Display Step Size

Communication: Set full-duplex (1) or half duplex (0)

Factory default settings: Write Data to the EEPROM (TAC protected)

Read / modify filter mode: IIR (0) or FIR (1)

Digital low pass filter: Filter Cut-off Frequency

Firmware type, check weighing, weighing filler, dose out, loss in

weight

Firmware Update (program PFL.exe and file FWUPDATE.zip needed)

Output: Get Triggered Average Value

Output: Get ADC Sample Value

Hysteresis for Setpoint H0 (S0) or H1 (S1) or H2 (S2)

Trigger function: Hold time for Violation of Setpoint Limit

Device information: Identify Device

Loading...

Loading...