109

EN

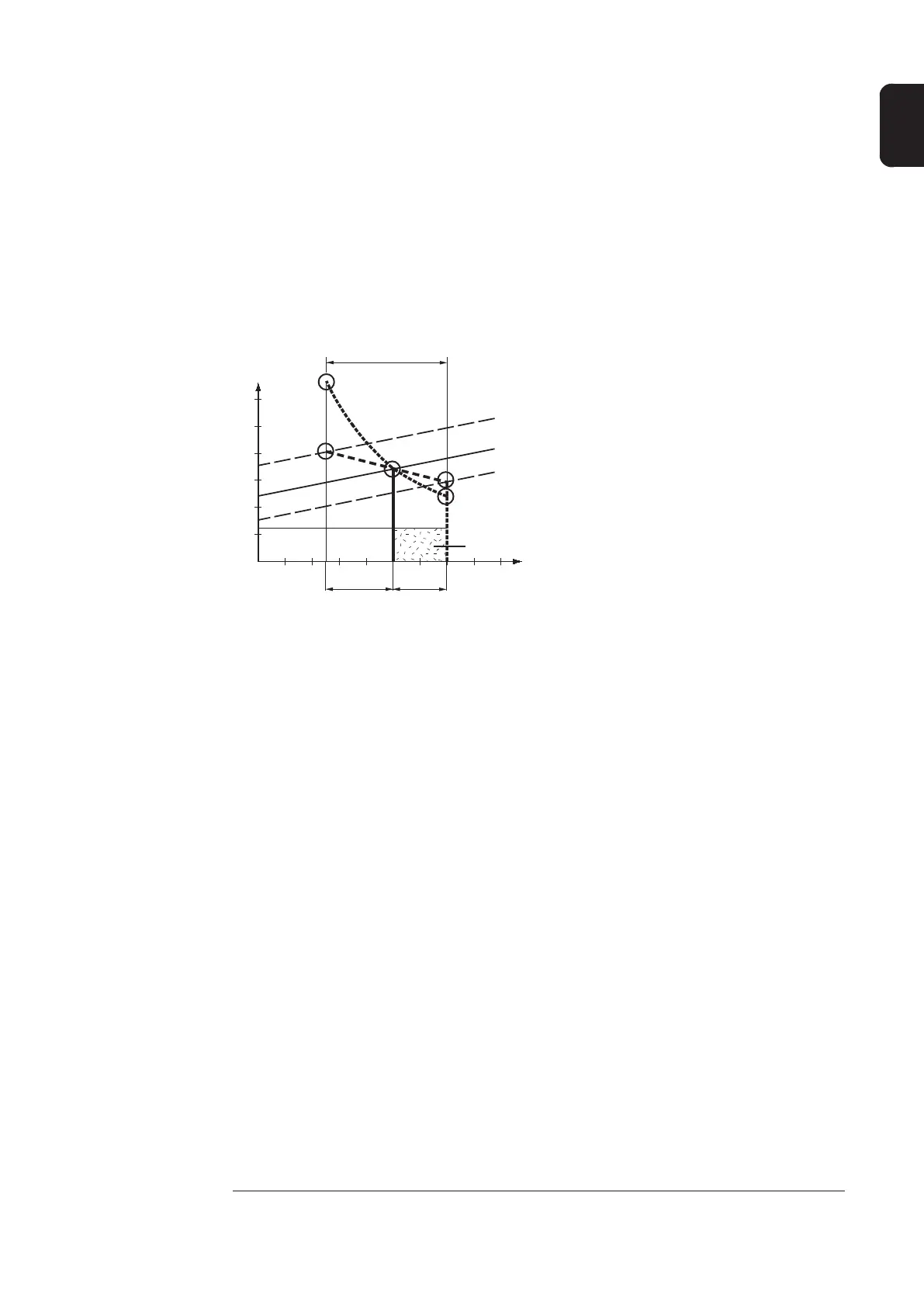

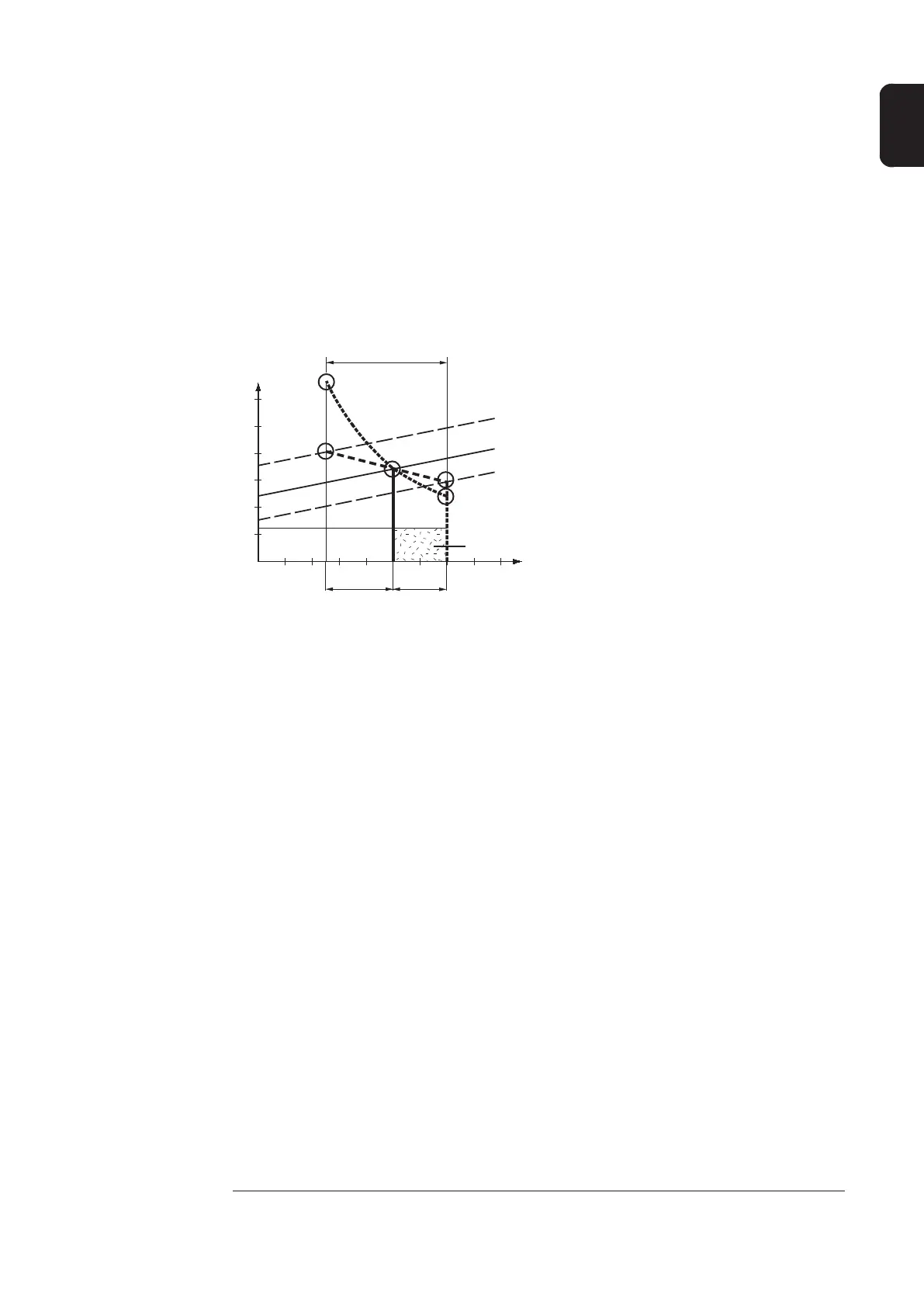

0.1 - 20.0 A/V

(drooping characteris-

tic with adjustable

slope)

- Parameter "0.1 - 20" is used to set a drooping characteristic

(5). The setting range extends from 0.1 A / V (very steep)

to 20 A / V (very flat).

- Setting a flat characteristic (5) is only advisable for cellu-

lose electrodes.

P-constant

(constant welding pow-

er)

- If the "P-constant" parameter is set, the welding power is

kept constant, irrespective of the welding voltage and weld-

ing current. This results in a hyperbolic characteristic (6).

- The "P-constant" parameter is particularly suitable for cel-

lulose electrodes, as well as for arc air gouging.

- For arc air gouging, set the arc-force dynamic to "100".

(1) Load line for rod electrode

(2) Load line for rod electrode where

arc length is increased

(3) Load line for rod electrode where

arc length is reduced

(4) Characteristic where "I-constant"

parameter is selected (constant

welding current)

(5) Characteristic where "0.1 - 20" pa-

rameter is selected (drooping

characteristic with adjustable

slope)

(6) Characteristic where "P-constant"

parameter is selected (constant

welding power)

(8) Example of pre-set arc-force dynamic where characteristic (5) or (6) is selected

(9) Possible change in the current where characteristic (5) or (6) is selected, as a

function of the welding voltage (arc length)

(a) Operating point where arc length is long

(b) Operating point where welding current I

H

is set

(c) Operating point where arc length is short

The characteristics (4), (5) and (6) shown here apply when using a rod electrode whose

characteristic corresponds - at a given arc length - to the load line (1).

Depending on what welding current (I) has been set, the point of intersection (operating

point) of characteristics (4), (5) and (6) will be displaced along the load line (1). The op-

erating point provides information on the actual welding voltage and the actual welding

current.

Where the welding current (I

H

) is permanently set, the operating point may migrate along

the characteristics (4), (5) and (6) according to the welding voltage at a given moment.

The welding voltage U is dependent upon the length of the arc.

If the arc length changes (e.g. in accordance with the load line (2)) the resulting operating

point will be the point where the corresponding characteristic (4), (5) or (6) intersects with

the load line (2).

Applies to characteristics (5) and (6): Depending upon the welding voltage (arc length),

the welding current (I) will also become either smaller or larger, even though the value set

for I

H

remains the same.

10

20

30

40

50

60

U (V)

004003001 200

I (A)

I

H

+ DynamikI

H

- 50 %

(8)

(2)

(1)

(3)

(7)

(c)

(c)

(b)

(a)

(a)

(6)

(5)

(4)

Loading...

Loading...