GE Power Management 269Plus Motor Management Relay 3-

61

3 SETUP AND USE THERMAL MEMORY

3

b) RTD INPUT TO THERMAL MEMORY

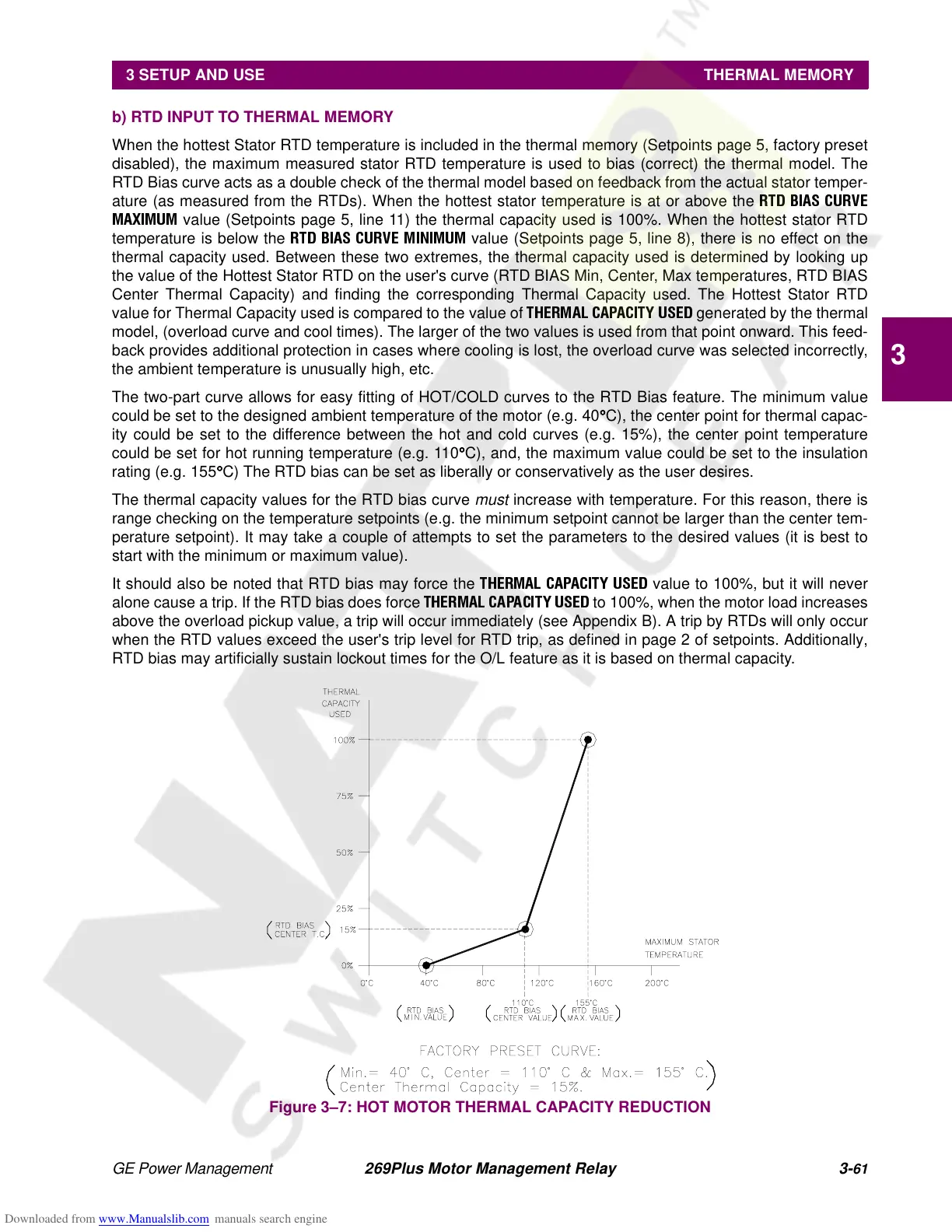

When the hottest Stator RTD temperature is included in the thermal memory (Setpoints page 5, factory preset

disabled), the maximum measured stator RTD temperature is used to bias (correct) the thermal model. The

RTD Bias curve acts as a double check of the thermal model based on feedback from the actual stator temper-

ature (as measured from the RTDs). When the hottest stator temperature is at or above the

RTD BIAS CURVE

MAXIMUM

value (Setpoints page 5, line 11) the thermal capacity used is 100%. When the hottest stator RTD

temperature is below the

RTD BIAS CURVE MINIMUM

value (Setpoints page 5, line 8), there is no effect on the

thermal capacity used. Between these two extremes, the thermal capacity used is determined by looking up

the value of the Hottest Stator RTD on the user's curve (RTD BIAS Min, Center, Max temperatures, RTD BIAS

Center Thermal Capacity) and finding the corresponding Thermal Capacity used. The Hottest Stator RTD

value for Thermal Capacity used is compared to the value of

THERMAL CAPACITY USED

generated by the thermal

model, (overload curve and cool times). The larger of the two values is used from that point onward. This feed-

back provides additional protection in cases where cooling is lost, the overload curve was selected incorrectly,

the ambient temperature is unusually high, etc.

The two-part curve allows for easy fitting of HOT/COLD curves to the RTD Bias feature. The minimum value

could be set to the designed ambient temperature of the motor (e.g. 40°

°°

°C), the center point for thermal capac-

ity could be set to the difference between the hot and cold curves (e.g. 15%), the center point temperature

could be set for hot running temperature (e.g. 110°

°°

°C), and, the maximum value could be set to the insulation

rating (e.g. 155°

°°

°C) The RTD bias can be set as liberally or conservatively as the user desires.

The thermal capacity values for the RTD bias curve

must

increase with temperature. For this reason, there is

range checking on the temperature setpoints (e.g. the minimum setpoint cannot be larger than the center tem-

perature setpoint). It may take a couple of attempts to set the parameters to the desired values (it is best to

start with the minimum or maximum value).

It should also be noted that RTD bias may force the

THERMAL CAPACITY USED

value to 100%, but it will never

alone cause a trip. If the RTD bias does force

THERMAL CAPACITY USED

to 100%, when the motor load increases

above the overload pickup value, a trip will occur immediately (see Appendix B). A trip by RTDs will only occur

when the RTD values exceed the user's trip level for RTD trip, as defined in page 2 of setpoints. Additionally,

RTD bias may artificially sustain lockout times for the O/L feature as it is based on thermal capacity.

Figure 3–7: HOT MOTOR THERMAL CAPACITY REDUCTION

Loading...

Loading...