GE Power Management 269Plus Motor Management Relay

iii

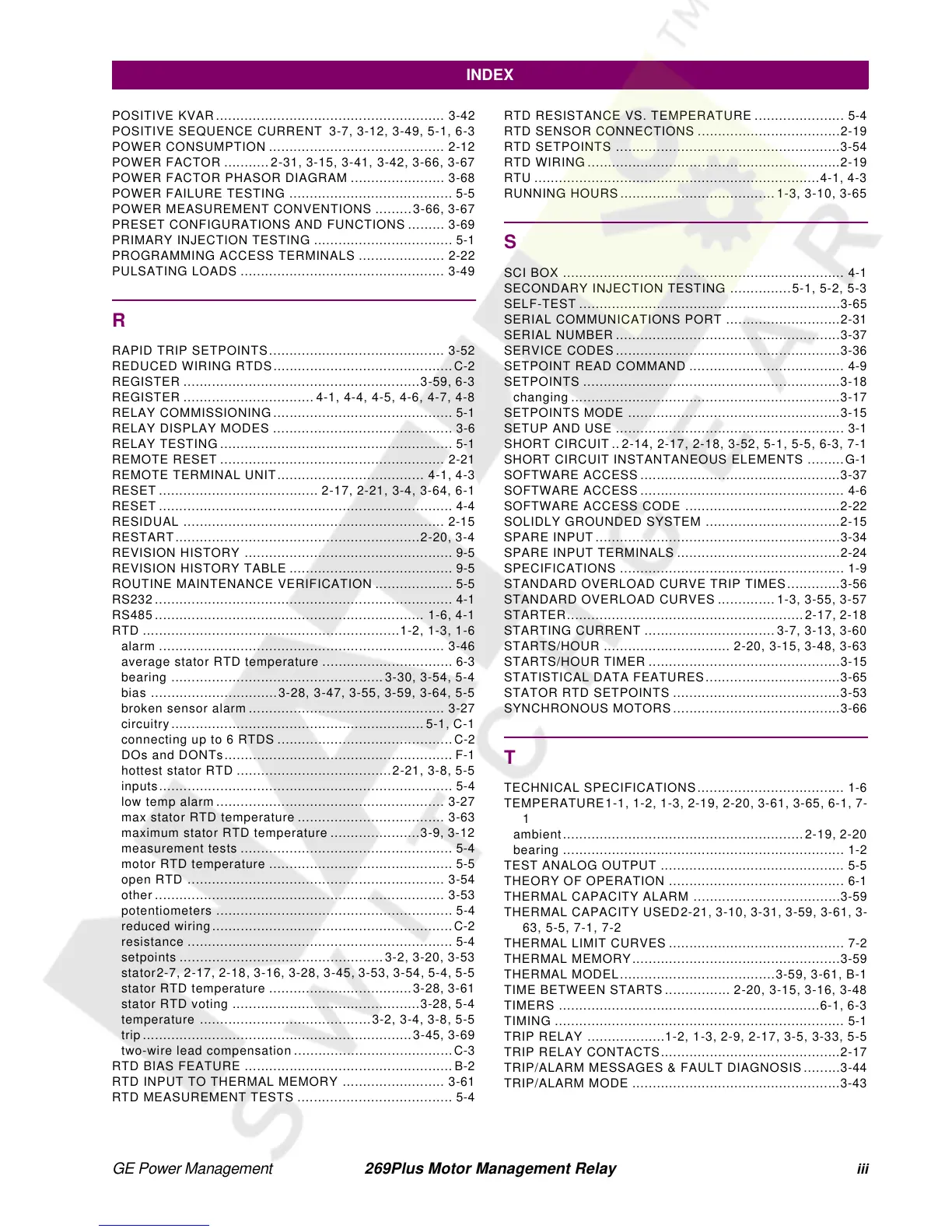

INDEX

POSITIVE KVAR........................................................ 3-42

POSITIVE SEQUENCE CURRENT 3-7, 3-12, 3-49, 5-1, 6-3

POWER CONSUMPTION ........................................... 2-12

POWER FACTOR ...........2-31, 3-15, 3-41, 3-42, 3-66, 3-67

POWER FACTOR PHASOR DIAGRAM ....................... 3-68

POWER FAILURE TESTING ........................................ 5-5

POWER MEASUREMENT CONVENTIONS .........3-66, 3-67

PRESET CONFIGURATIONS AND FUNCTIONS ......... 3-69

PRIMARY INJECTION TESTING .................................. 5-1

PROGRAMMING ACCESS TERMINALS ..................... 2-22

PULSATING LOADS .................................................. 3-49

R

RAPID TRIP SETPOINTS........................................... 3-52

REDUCED WIRING RTDS............................................C-2

REGISTER ..........................................................3-59, 6-3

REGISTER ................................ 4-1, 4-4, 4-5, 4-6, 4-7, 4-8

RELAY COMMISSIONING............................................ 5-1

RELAY DISPLAY MODES ............................................ 3-6

RELAY TESTING......................................................... 5-1

REMOTE RESET ....................................................... 2-21

REMOTE TERMINAL UNIT.................................... 4-1, 4-3

RESET ....................................... 2-17, 2-21, 3-4, 3-64, 6-1

RESET ........................................................................ 4-4

RESIDUAL ................................................................ 2-15

RESTART............................................................2-20, 3-4

REVISION HISTORY ................................................... 9-5

REVISION HISTORY TABLE ........................................ 9-5

ROUTINE MAINTENANCE VERIFICATION ................... 5-5

RS232......................................................................... 4-1

RS485.................................................................. 1-6, 4-1

RTD ...............................................................1-2, 1-3, 1-6

alarm ...................................................................... 3-46

average stator RTD temperature ................................ 6-3

bearing ....................................................3-30, 3-54, 5-4

bias ...............................3-28, 3-47, 3-55, 3-59, 3-64, 5-5

broken sensor alarm ................................................ 3-27

circuitry..............................................................5-1, C-1

connecting up to 6 RTDS ...........................................C-2

DOs and DONTs........................................................ F-1

hottest stator RTD ......................................2-21, 3-8, 5-5

inputs........................................................................ 5-4

low temp alarm........................................................ 3-27

max stator RTD temperature .................................... 3-63

maximum stator RTD temperature ......................3-9, 3-12

measurement tests .................................................... 5-4

motor RTD temperature ............................................. 5-5

open RTD ............................................................... 3-54

other ....................................................................... 3-53

potentiometers .......................................................... 5-4

reduced wiring...........................................................C-2

resistance ................................................................. 5-4

setpoints ..................................................3-2, 3-20, 3-53

stator2-7, 2-17, 2-18, 3-16, 3-28, 3-45, 3-53, 3-54, 5-4, 5-5

stator RTD temperature ...................................3-28, 3-61

stator RTD voting ..............................................3-28, 5-4

temperature ..........................................3-2, 3-4, 3-8, 5-5

trip..................................................................3-45, 3-69

two-wire lead compensation .......................................C-3

RTD BIAS FEATURE ...................................................B-2

RTD INPUT TO THERMAL MEMORY ......................... 3-61

RTD MEASUREMENT TESTS ...................................... 5-4

RTD RESISTANCE VS. TEMPERATURE ...................... 5-4

RTD SENSOR CONNECTIONS ...................................2-19

RTD SETPOINTS .......................................................3-54

RTD WIRING ..............................................................2-19

RTU ......................................................................4-1, 4-3

RUNNING HOURS......................................1-3, 3-10, 3-65

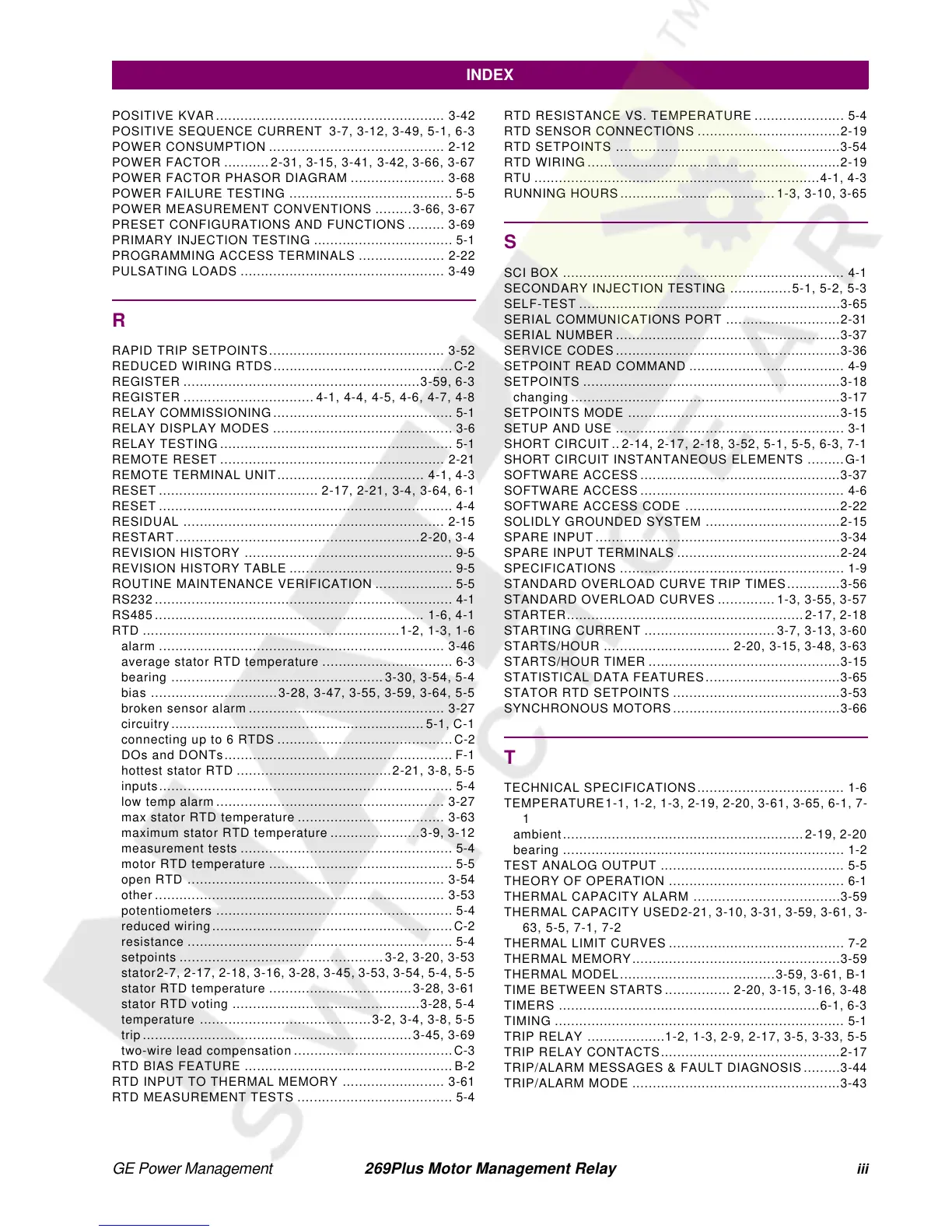

S

SCI BOX ..................................................................... 4-1

SECONDARY INJECTION TESTING ...............5-1, 5-2, 5-3

SELF-TEST ................................................................3-65

SERIAL COMMUNICATIONS PORT ............................2-31

SERIAL NUMBER .......................................................3-37

SERVICE CODES.......................................................3-36

SETPOINT READ COMMAND ...................................... 4-9

SETPOINTS ...............................................................3-18

changing ..................................................................3-17

SETPOINTS MODE ....................................................3-15

SETUP AND USE ........................................................ 3-1

SHORT CIRCUIT .. 2-14, 2-17, 2-18, 3-52, 5-1, 5-5, 6-3, 7-1

SHORT CIRCUIT INSTANTANEOUS ELEMENTS .........G-1

SOFTWARE ACCESS .................................................3-37

SOFTWARE ACCESS .................................................. 4-6

SOFTWARE ACCESS CODE ......................................2-22

SOLIDLY GROUNDED SYSTEM .................................2-15

SPARE INPUT............................................................3-34

SPARE INPUT TERMINALS ........................................2-24

SPECIFICATIONS ....................................................... 1-9

STANDARD OVERLOAD CURVE TRIP TIMES.............3-56

STANDARD OVERLOAD CURVES ..............1-3, 3-55, 3-57

STARTER..........................................................2-17, 2-18

STARTING CURRENT ................................3-7, 3-13, 3-60

STARTS/HOUR ............................... 2-20, 3-15, 3-48, 3-63

STARTS/HOUR TIMER ...............................................3-15

STATISTICAL DATA FEATURES.................................3-65

STATOR RTD SETPOINTS .........................................3-53

SYNCHRONOUS MOTORS.........................................3-66

T

TECHNICAL SPECIFICATIONS.................................... 1-6

TEMPERATURE1-1,1-2,1-3,2-19,2-20,3-61,3-65,6-1,7-

1

ambient...........................................................2-19, 2-20

bearing ..................................................................... 1-2

TEST ANALOG OUTPUT ............................................. 5-5

THEORY OF OPERATION ........................................... 6-1

THERMAL CAPACITY ALARM ....................................3-59

THERMAL CAPACITY USED2-21, 3-10, 3-31, 3-59, 3-61, 3-

63,5-5,7-1,7-2

THERMAL LIMIT CURVES ........................................... 7-2

THERMAL MEMORY...................................................3-59

THERMAL MODEL......................................3-59, 3-61, B-1

TIME BETWEEN STARTS................ 2-20, 3-15, 3-16, 3-48

TIMERS ................................................................6-1, 6-3

TIMING ....................................................................... 5-1

TRIP RELAY ...................1-2, 1-3, 2-9, 2-17, 3-5, 3-33, 5-5

TRIP RELAY CONTACTS............................................2-17

TRIP/ALARM MESSAGES & FAULT DIAGNOSIS.........3-44

TRIP/ALARM MODE ...................................................3-43

Loading...

Loading...