Start-Up and Operation

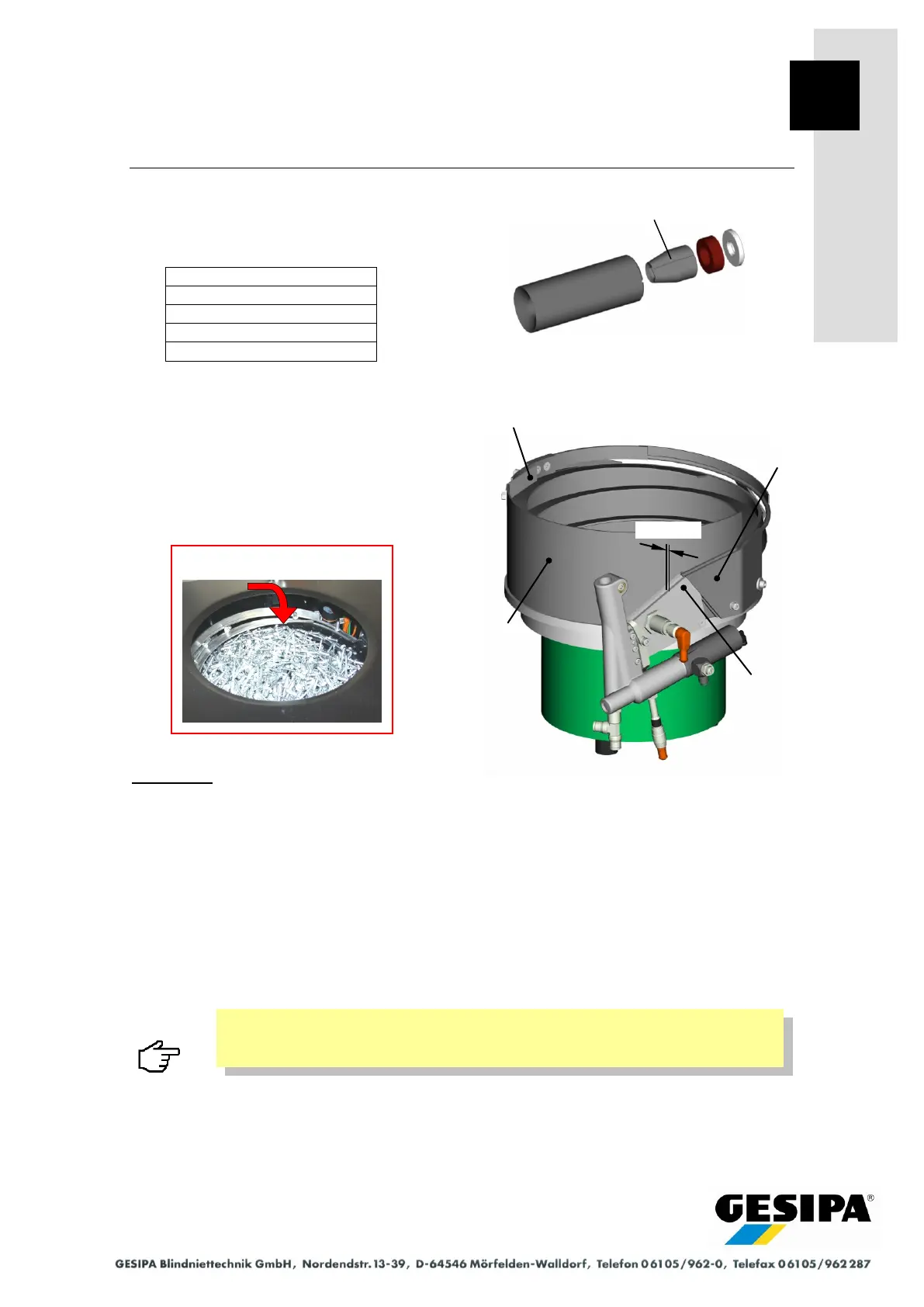

- jaws corresponding to the diameter of the

blind rivet mandrel are used. The jaw sizes

are graduated as follows:

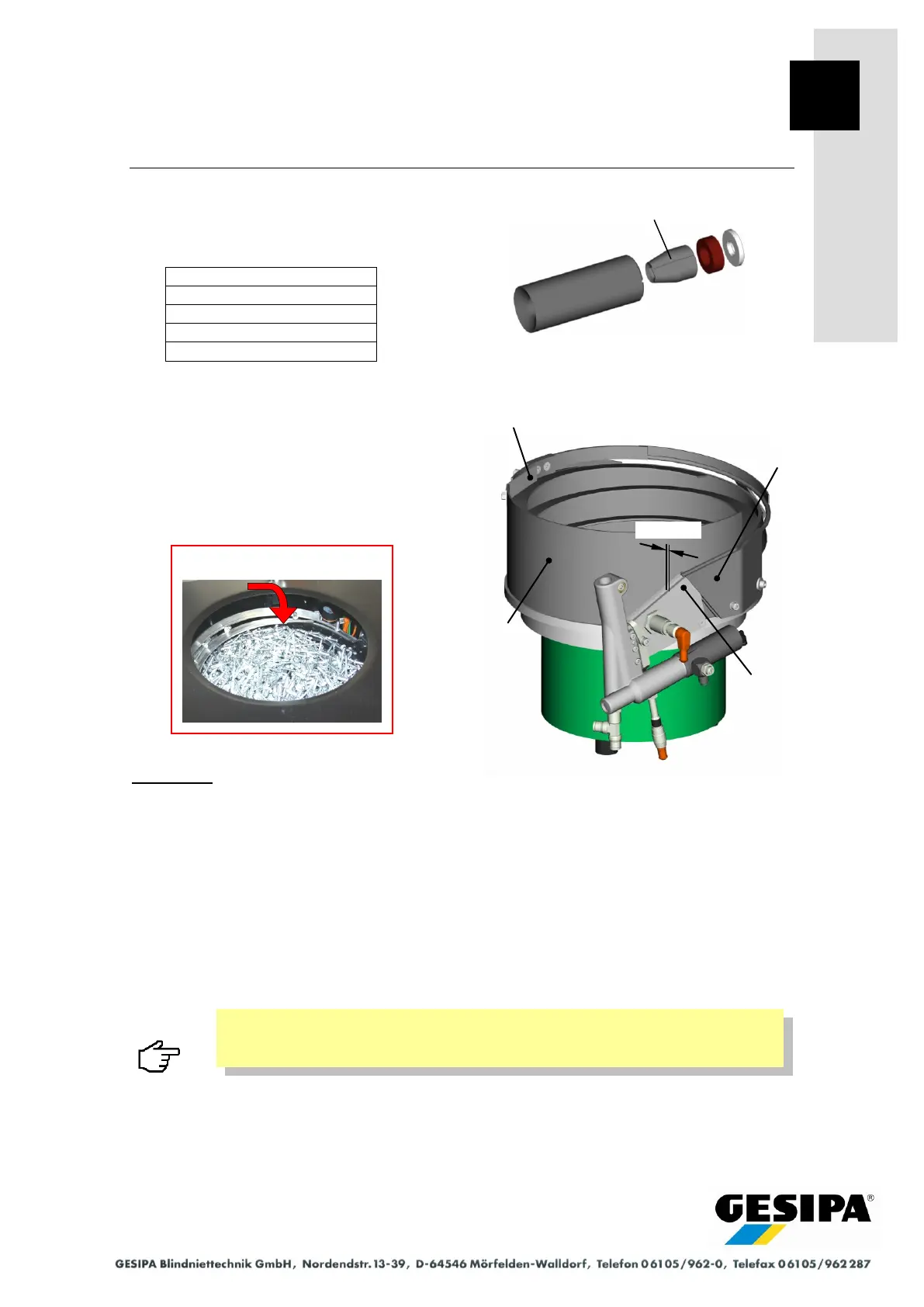

- the adjustable baffle ahead of the outlet

channel of the vibration feed container is

set such that only one blind rivet can pass

through this chicane.

- the spacing between the chute plates is

set to approx. the mandrel diameter +0.5

mm.

Operation

Insert the blind rivet, set in the working position in the riveting gun, in the blind rivet hole up to

the setting head.

The riveting operation is triggered by pressing the triggering button, the spent mandrel is re-

moved and the next blind rivet is automatically made available in the working position.

Immediately after the blind rivet mandrel has broken off, the blind riveting gun must be pulled

back from the riveting point to ensure the next blind rivet can be fed in unobstructed from the

spreader nosepiece.

The spent mandrels are automatically conveyed to the spent mandrel container. The evacua-

tion system is then switched off automatically.

The spent mandrel container can hold 1800 to 5500 spent mandrels (depending

on the size). Ensure the spent mandrel container is emptied in good time.

The blind riveting gun can be conveniently suspended from the balancer at the workplace.

The supply unit must only be placed on an even surface. The operator must always check

the stability.

Blind rivet mandrel diameter

Vibration feed con-

tainer

Loading...

Loading...