Start-Up and Operation

Prior to start-up, read and follow the GAV operat-

ing instructions and safety information. Also ob-

serve the generally applicable Occupational

Health and Safety Regulations.

Start-up

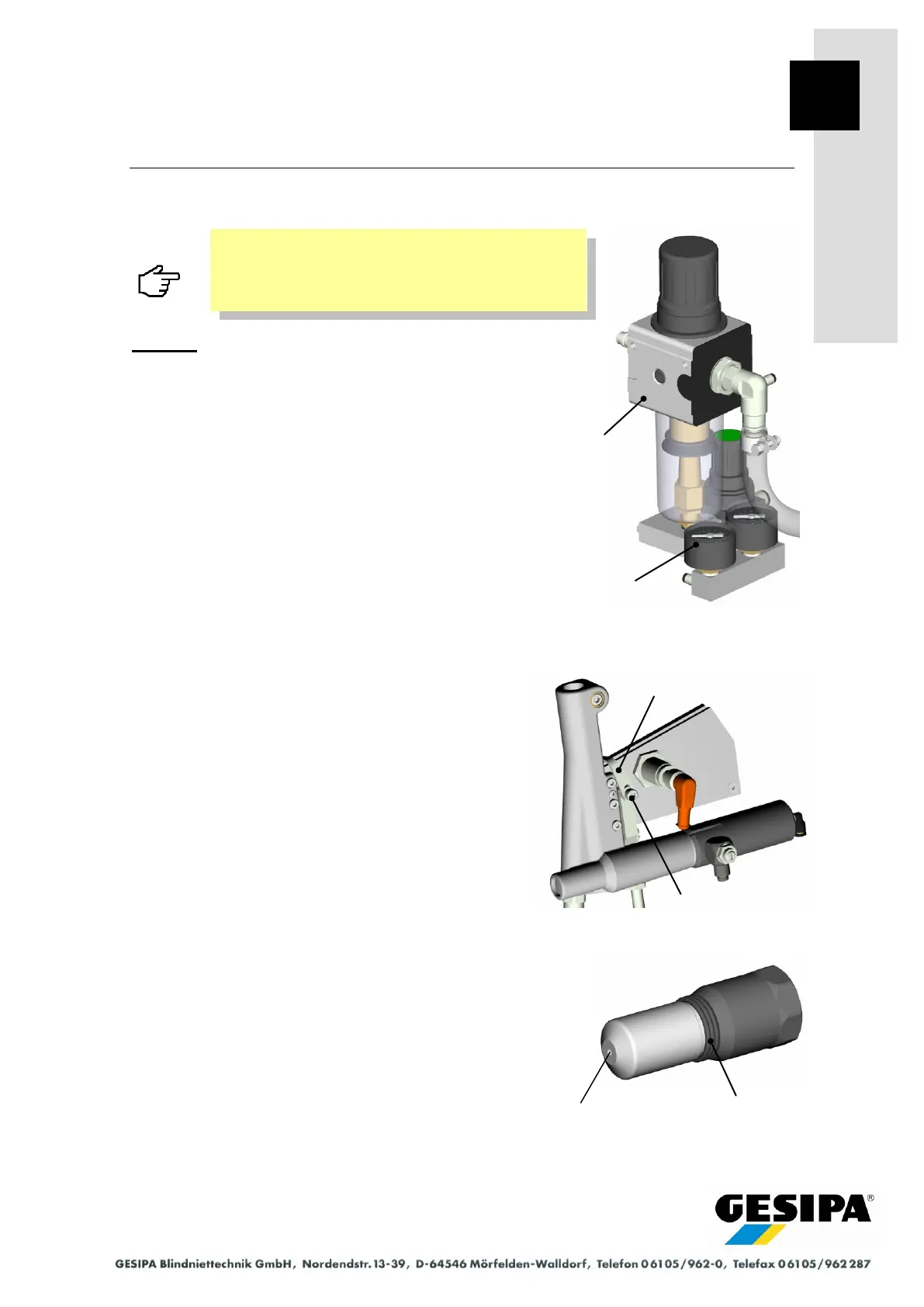

- Connect the device to the compressed air sup-

ply system.

- Set the operating pressure at the pressure re-

ducer valve to 6 bar, check on pressure gauge.

- Connect the power supply.

- Switch on the device at the master switch.

- Fill the vibration feed container half full with

blind rivets and switch on the vibration feed unit

(button F4, see Section 8 "Operation").

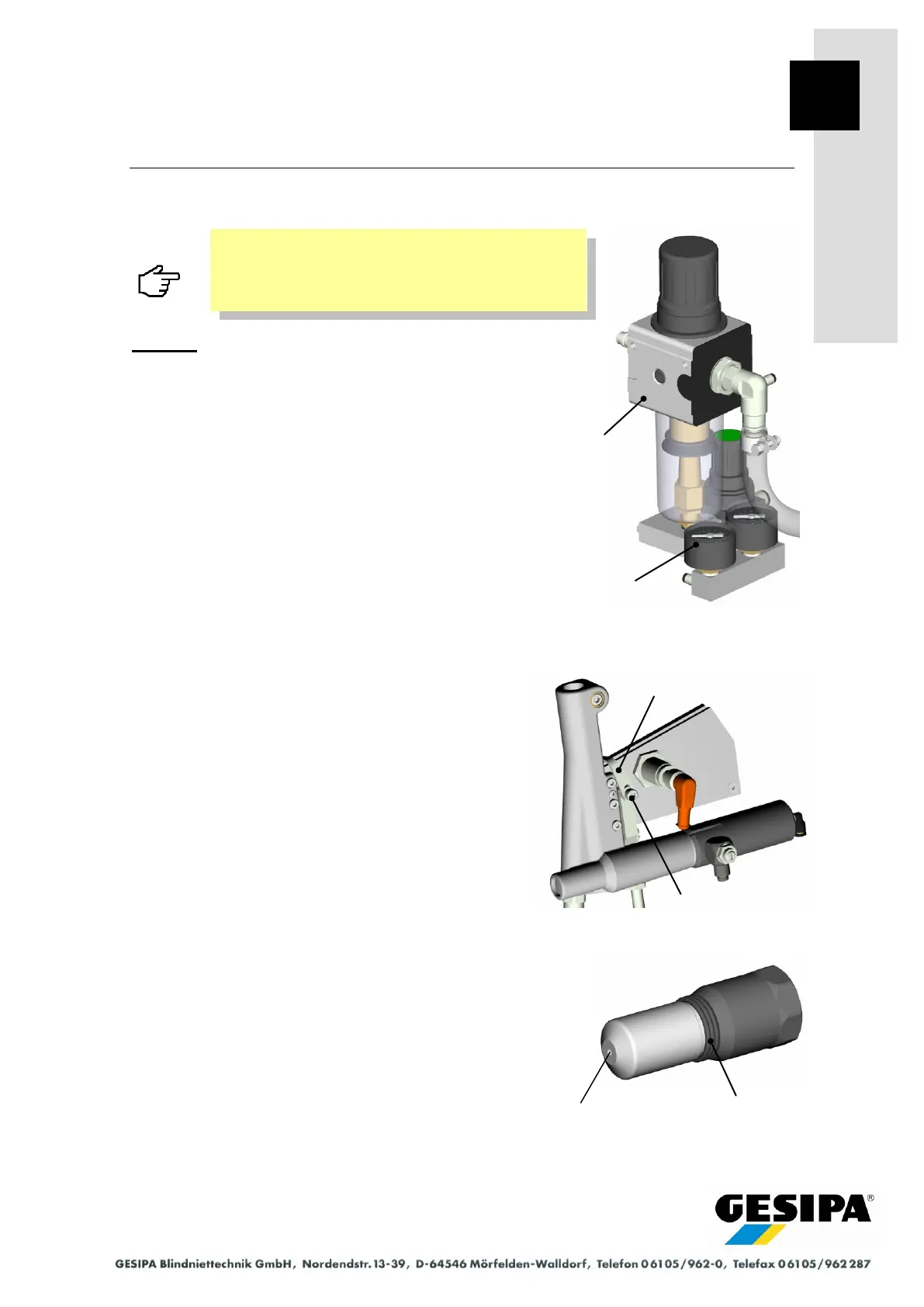

- Set the separator tongue at the setting screw

such that only one blind rivet at a time is sepa-

rated.

- Press "ON" button.

- Trigger blind riveting gun twice ("Cycle" func-

tion in "MAN" menu). The first blind rivet is

transferred to the spreader nosepiece.

As per the delivery specifications, the device is set

up for a certain size of blind rivet. Nevertheless

make sure that

- the inside diameter of the rivet feed hose is 2 - 3

mm larger than the setting head diameter of the

blind rivet (max. setting head diameter 11.4 mm)

- the hole of the spreader nosepiece 2-80 is 0.3

mm larger than the mandrel diameter of the blind

rivet. Spreader nosepieces with a cylindrical ex-

tension of up to 15 mm are available for difficult

to access riveting points (note length of blind riv-

et mandrel)

- the holding force of the spreader nosepiece 2-80

can be increased if necessary by fitting additional

O-rings.

Loading...

Loading...