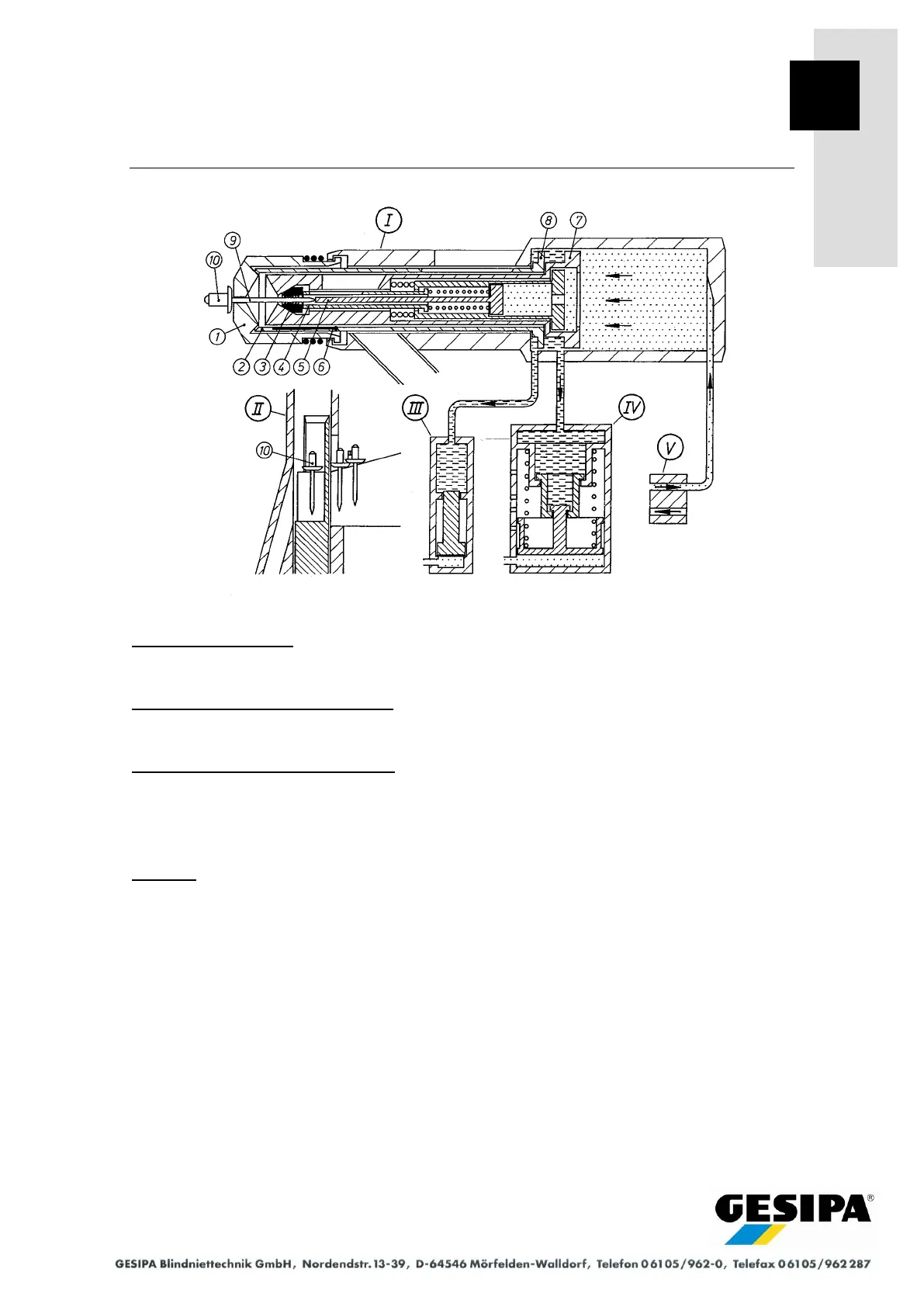

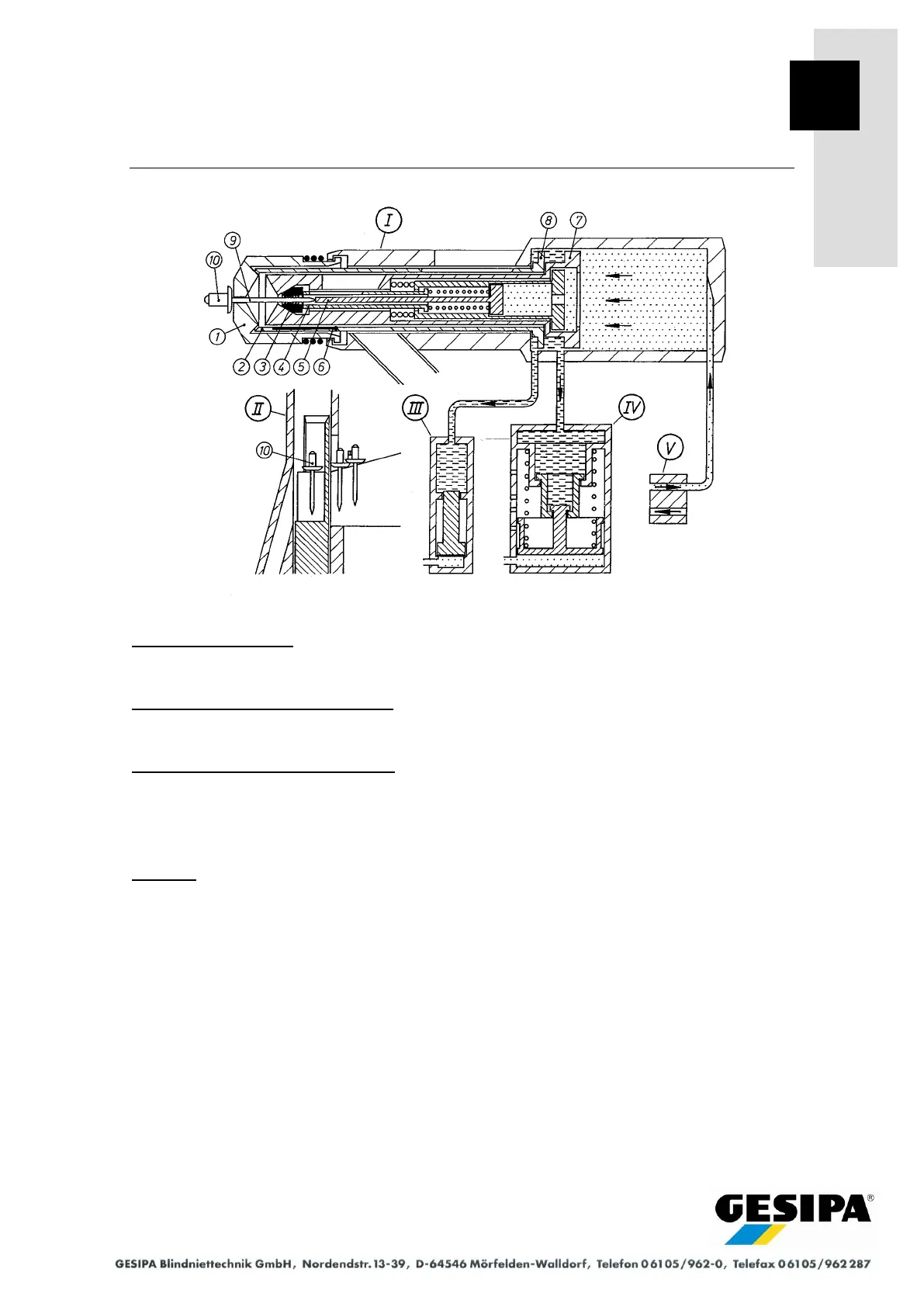

Functional Description

7 Functional Assemblies of the Supply Unit

Blind rivet separator (II)

Component part of the blind rivet feed system. Here the blind rivets (10) are separated and fed

by compressed air via the feed hose to the blind riveting gun.

Hydropneumatic pressure booster (III)

Applies pressure to the pressure piston (8), thus initiating the release stroke of the spreader

nosepiece.

Hydropneumatic pressure booster (IV)

Applies pressure to the pull piston (7) to initiate the rivet setting stroke and to the back of the

pressure piston (8) to lock the spreader nosepiece (1) during the setting procedure.

Cylinder switches send control pulses for the switching operations as the piston system moves

back and forth in the pressure booster (IV).

Valve (V)

Activates the reset air to return the complete piston unit (7/8) to its initial position. Correspond-

ing pistons use the reset air applied until the riveting procedure is completed to hold the stop

piston (5), jaw tube (4) as well as the closing sleeve (2) in the hold or end position.

Loading...

Loading...