9.4 Small Pressure Booster

GAV Settings

9.4 Small Pressure Booster

WS3 Displacement Sensor Calibration and Basic Setting

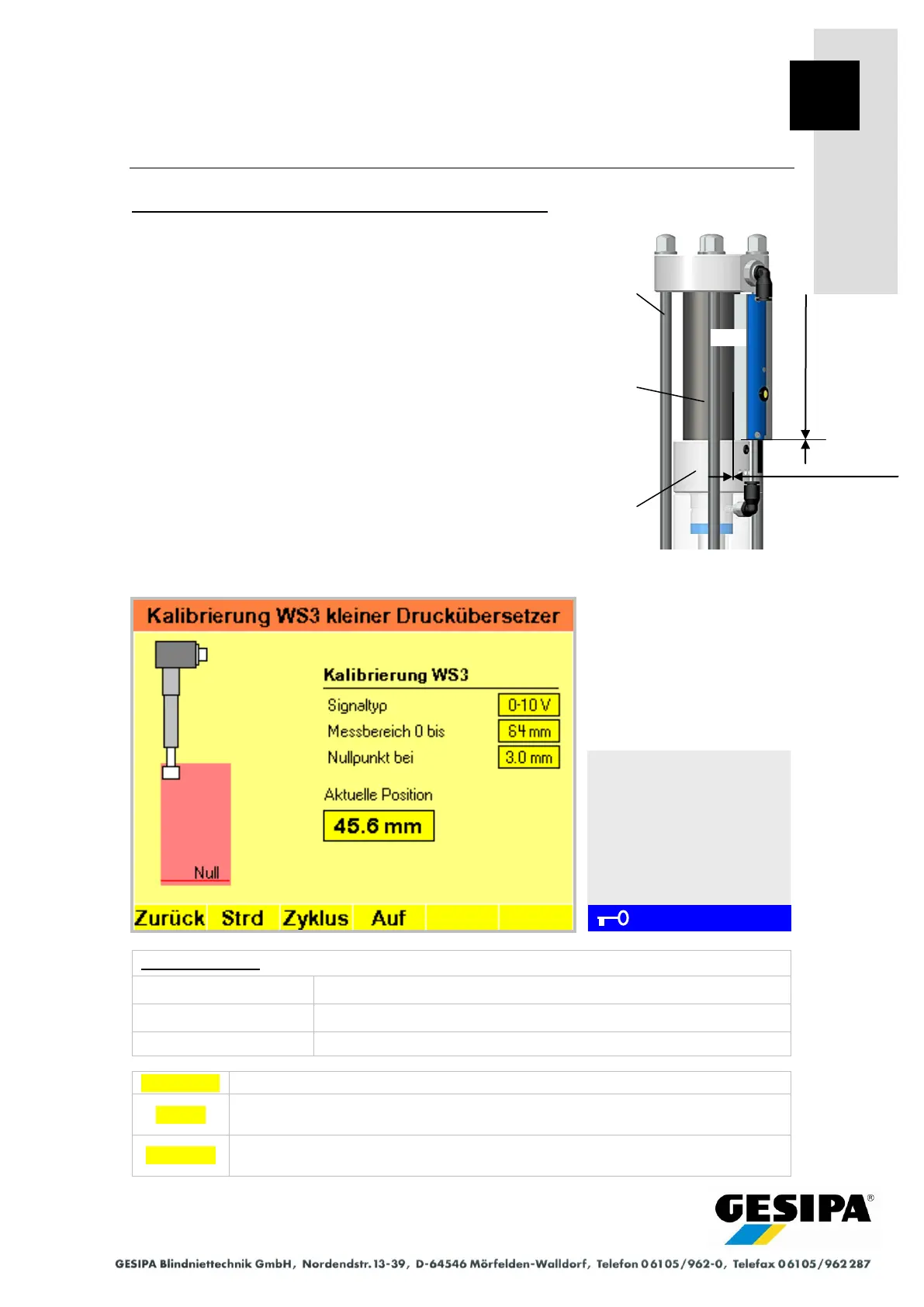

The displacement sensor (WS3) can be replaced with the pres-

sure booster installed in position. Based on the hydraulic con-

nection, the displacement sensor (WS3) should be installed on

the tie rod on the right-hand side.

When installing the displacement sensor (WS3) the cable side

of the sensor body must be directed with the sensor holder

downwards towards the top of the centre piece and the longitu-

dinal side of the displacement sensor (WS3) additionally

pressed flush against the cylinder wall and screwed in position.

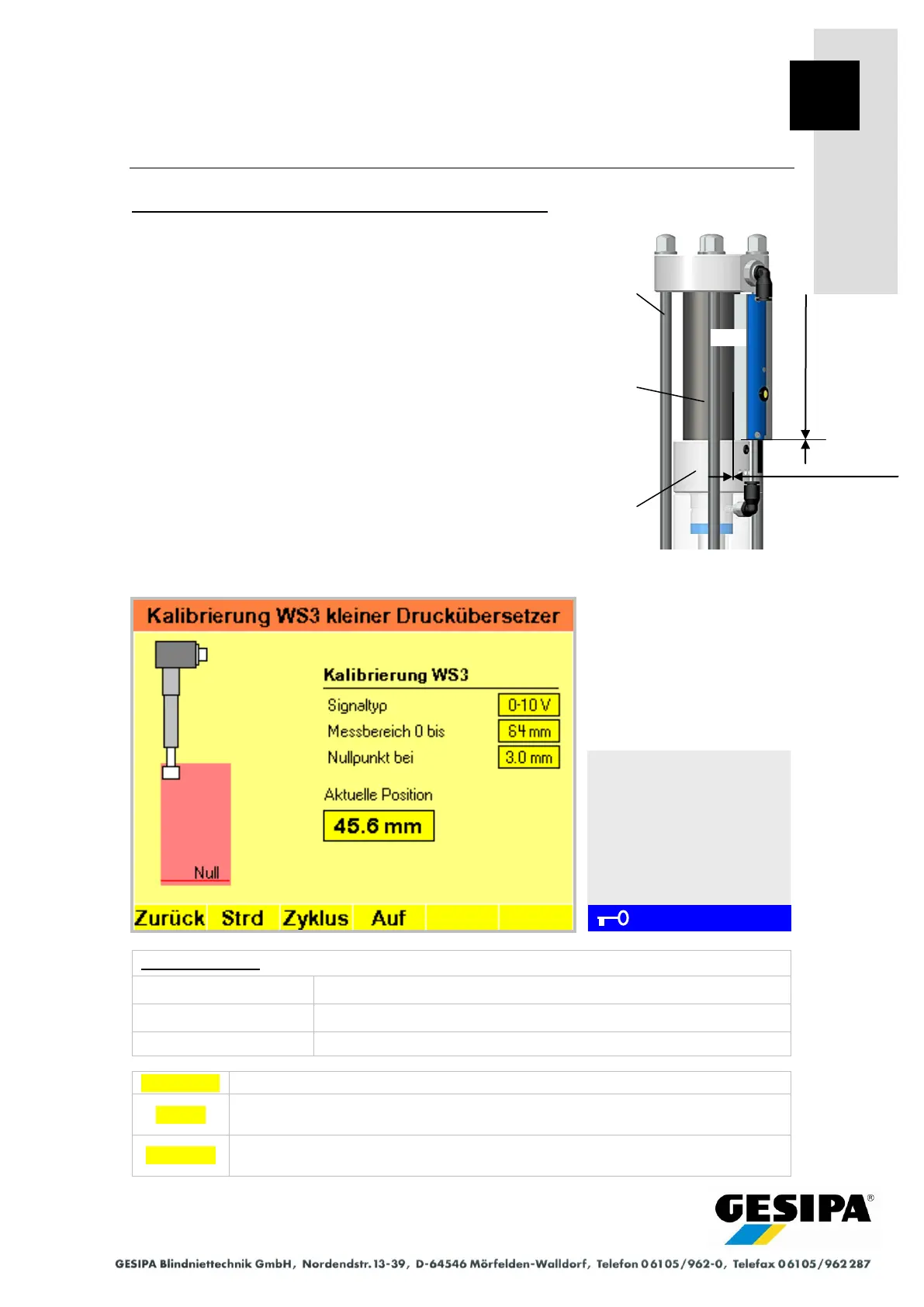

The calibration data "signal type" and "measuring range" are

set in the "WS3 Small Pressure Booster Calibration" menu dur-

ing device installation and must not be changed.

The basic setting of the pressure booster is achieved with the

"zero point" parameter. In the basic setting, "zero point" is set

such that the "current position" is 0.0 mm. The "zero point" pa-

rameter should then be between 2 and 4 mm. Slight corrections

can be made by shifting the displacement sensor in the pres-

sure booster.

Signal type of displacement sensor.

Measuring range of displacement sensor.

Zero point of displacement sensor.

Resets all settings to default.

Executes one processing cycle

(see Section 8.7 "Manual Operation" "Cycle" function).

Opens the riveting gun lock in home position

(see Section 8.7 "Manual Operation" "Lock Open" function).

Navigation:

AUTO

►MAN

► Menu

► GAV settings

► Small pressure booster

► Cal

Small pressure booster

calibration menu

WS3 displacement sensor

Installation dimen-

sion 0 mm

Installation dimen-

sion 0 mm

Loading...

Loading...