196

Maintenance

96-8000 rev R June 2007

PERIODIC M AINTENANCE

A periodic maintenance page is found within the Current Commands screens titled “Maintenance”. Access the

screen by pressing CURNT COMDS and using Page Up or Page Down to scroll to the page.

An item on the list can be selected by pressing the up and down arrow keys. The selected item is then activated or

deactivated by pressing Origin. If an item is active, the remaining hours will be displayed, a deactivated item will

display, “—” instead.

The maintenance item time is adjusted by using the left and right arrows. Pressing the Origin key will reinstate the

default time.

Items are tracked either by the time accumulated while power is on (ON-TIME) or by cycle-start time (CS-TIME).

When the time reaches zero the message “Maintenance Due” is displayed at the bottom of the screen (a negative

number of hours indicates the hours past due).

This message is not an alarm and does not interfere with machine operation in any way. After the necessary

maintenance has been performed, the operator can select that item on the “Maintenance” screen, press the Origin

button to deactivate it, then press Origin again to reactivate it with the default number of hours remaining.

Refer to settings 167-186 for additional maintenance defaults. Note that settings 181-186 are used as spare

maintenance alerts by keying-in a number. The maintenance number will display on the Current Commands page

once a value (time) is added to the setting.

WINDOWS / GUARDING

Polycarbonate windows and guarding can be weakened by exposure to cutting liquids and chemicals that contain

amines. It is possible to lose up to 10% of the remaining strength annually. If degradation is suspected, replace the

window. It is recommended that the windows be replaced every two years.

Windows and guarding should be replaced if damaged or severely scratched. Replace dam-

aged windows immediately.

WORKLIGHT

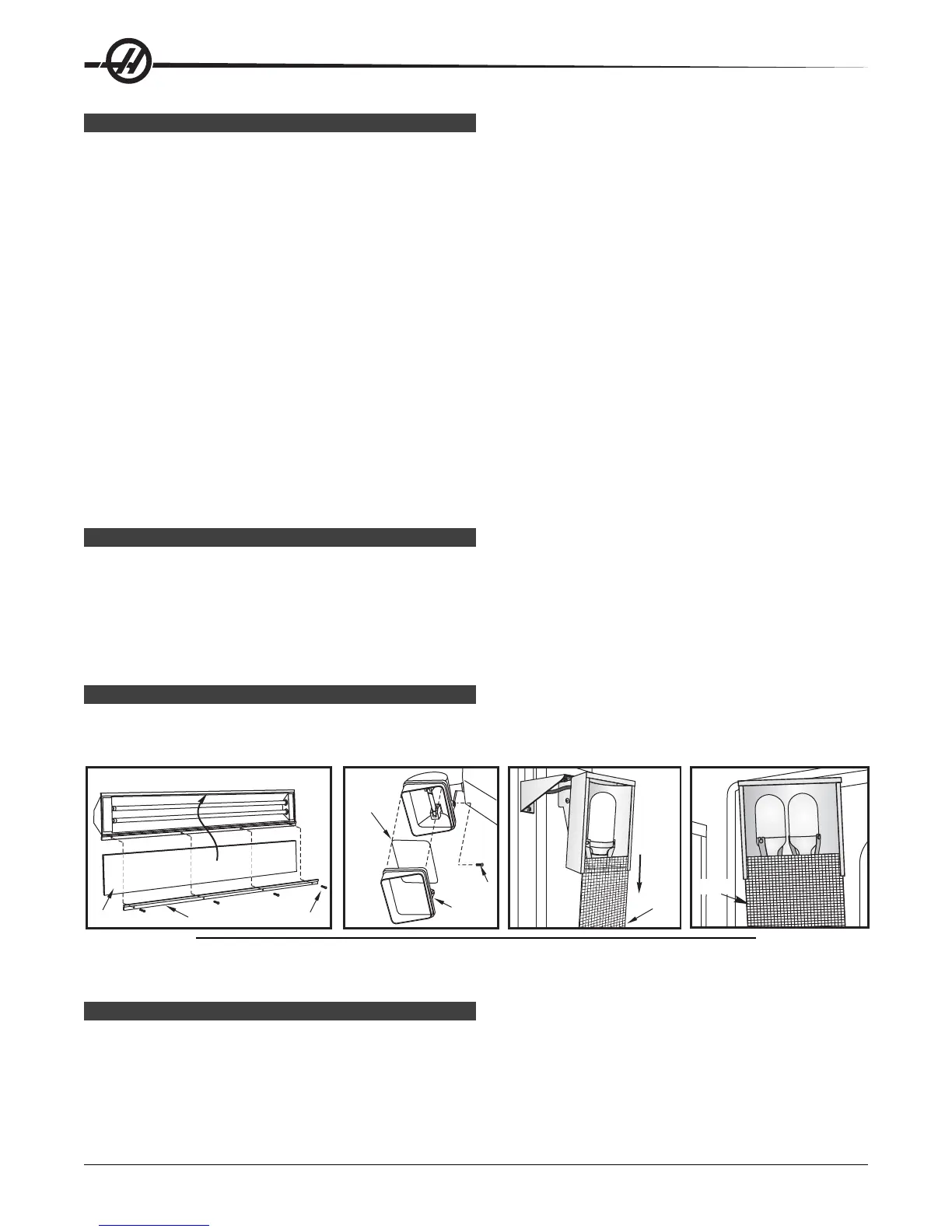

There are four types of worklights for the Haas mills. Turn off power to the machine at the main breaker before doing

any work on the mill.

Glass

Frame

Screw

Screws

Retainer

Lens

Lens

Lens

Note: The power for the worklight comes from the GFI circuit. If the worklight does

not turn on, check this first, it can be reset at the side of the control panel.

CHIP A UGER

During normal operation, most chips are discharged from the machine at the discharge tube. However, very small

chips may flow through the drain and collect in the coolant tank strainer. To prevent drain blockage, clean this

strainer regularly. Should the drain become clogged and cause coolant to collect in the pan, stop the machine,

loosen the chips blocking the drain, and allow the coolant to drain. Empty the coolant tank strainer, then resume

operation.

Loading...

Loading...