Maintenance

197

96-8000 rev R June 2007

SPINDLE A IR P RESSURE

Verify Spindle air pressure using the gauge located behind the main air regulator. VF, VR, and VS mills should be

set to 17 psi. EC-series and HS Series should be set to 25psi. Adjust if necessary.

12K & 15K Spindle

The air pressure for 12K &15K Spindles is 20 psi. The 12K &15K Spindles require higher pressure to slightly

reduce the delivery speed and amount of oil on the bearings.

TSC MAINTENANCE

The TSC pump is a precision gear pump and will wear out faster and lose pressure if abrasive particles are present

in the coolant.

• Check the dirt indicator on the 20-micron mesh filter with the TSC system running and no tool in the spindle.

Change the element when the indicator reaches the red zone.

• Clean the pump intake filter when indicator is in the red zone. Reset indicator with button. Gate filters can be

cleaned with a wire brush.

• After changing or cleaning filter elements, run the TSC system with no tool in spindle for at least one minute to

prime system.

• Coolant will be used more quickly when the TSC system is in use. Make sure to keep the coolant level up and

check the level more frequently (check after every eight hour shift). Premature wear of the pump can result

from running with a low coolant level in the tank.

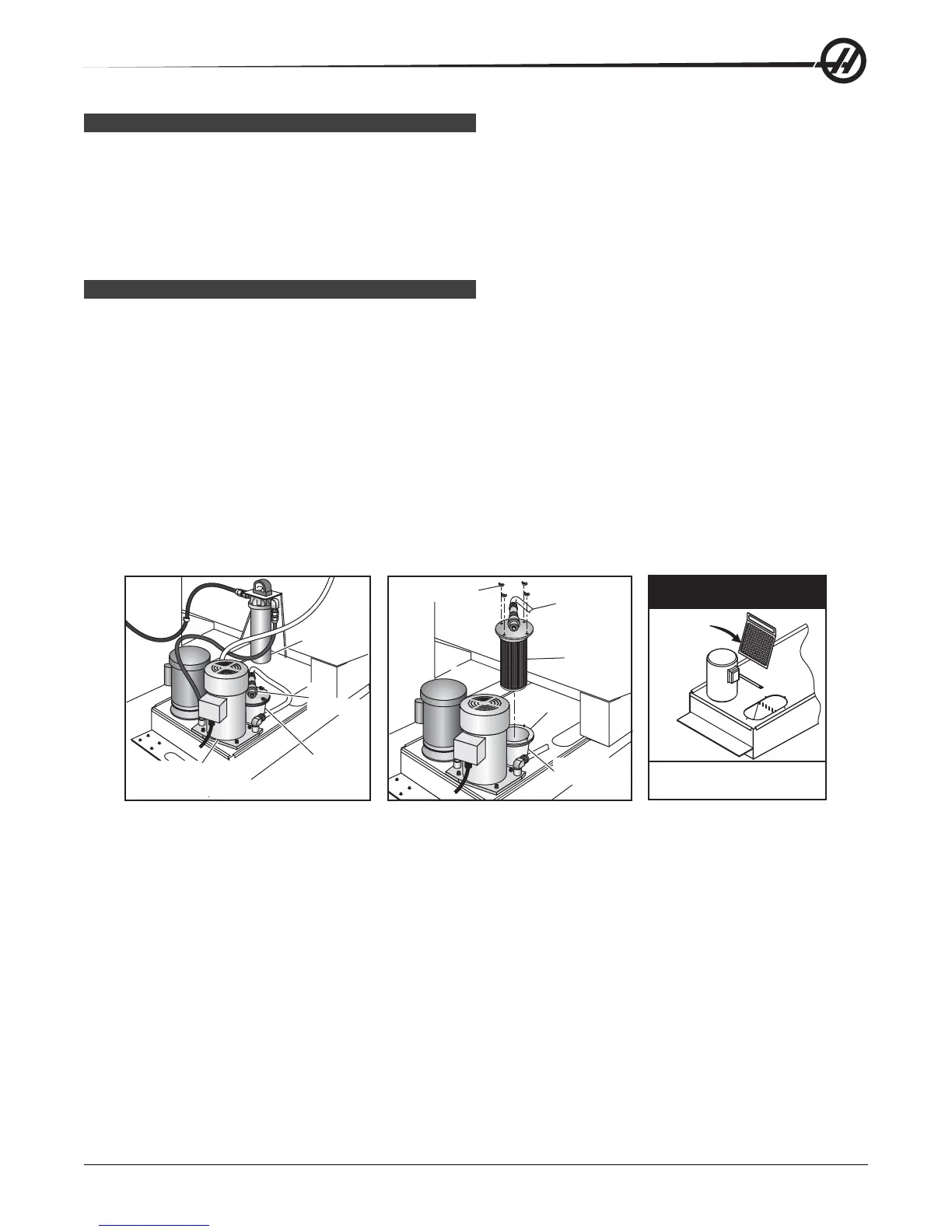

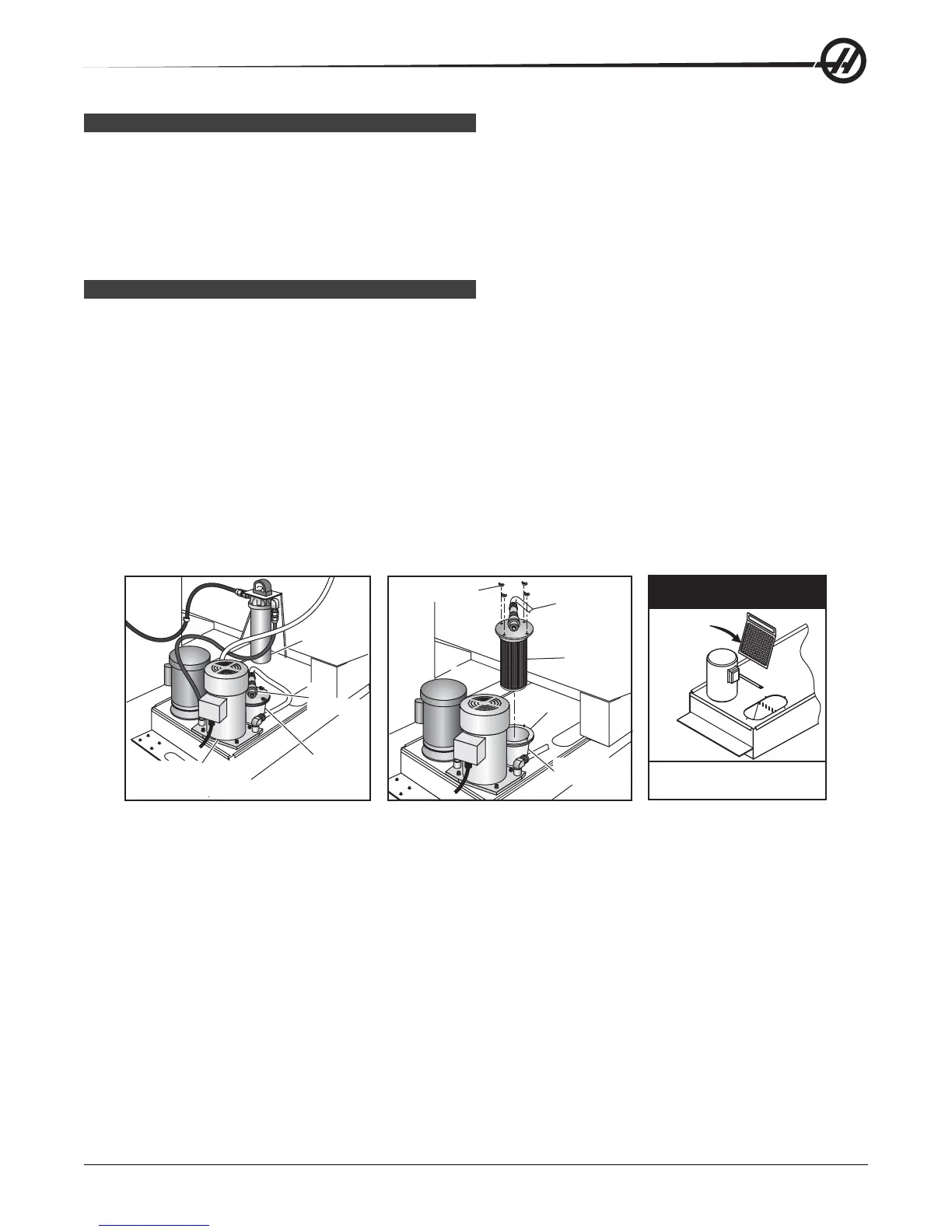

Intake Filter

Assembly

TSC Filter

Assembly

Dirt

Indicator

TSC Coolant

Pump Assembly

Wing Nuts (4)

Gasket

20 Mesh

Intake

Filter

Disconnect

Hose for

Cleaning

Intake Filter

Housing

IMPORTANT!

CLEAN THE GATE FILTER

REGULARLY

GATE

FILTER

TSC Coolant Pump Assembly Cleaning the Intake Filter Gate Filter

Warnings

Use of coolants with extremely low lubricity can damage the TSC coolant tip and pump.

Shortened pump life, reduction of pressure and increased maintenance are normal and to be expected in abrasive

environments and are not covered by warranty. A special filter, in addition to the standard filter should be used;

contact Haas for recommendations.

Machining of ceramics and the like voids all warranty claims for wear and is done entirely at customer's risk.

Increased maintenance schedules are absolutely required with abrasive swarf. The coolant must be changed more

often and the tank thoroughly cleaned of sediment on the bottom. An auxiliary coolant filter is recommended.

When machining castings, sand from the casting process and the abrasive properties of cast aluminum and cast

iron will shorten pump life unless a special filter is used in addition to the 20 mesh intake filter. Contact Haas for

recommendations.

Loading...

Loading...