23

Introduction

96-8000 rev R June 2007

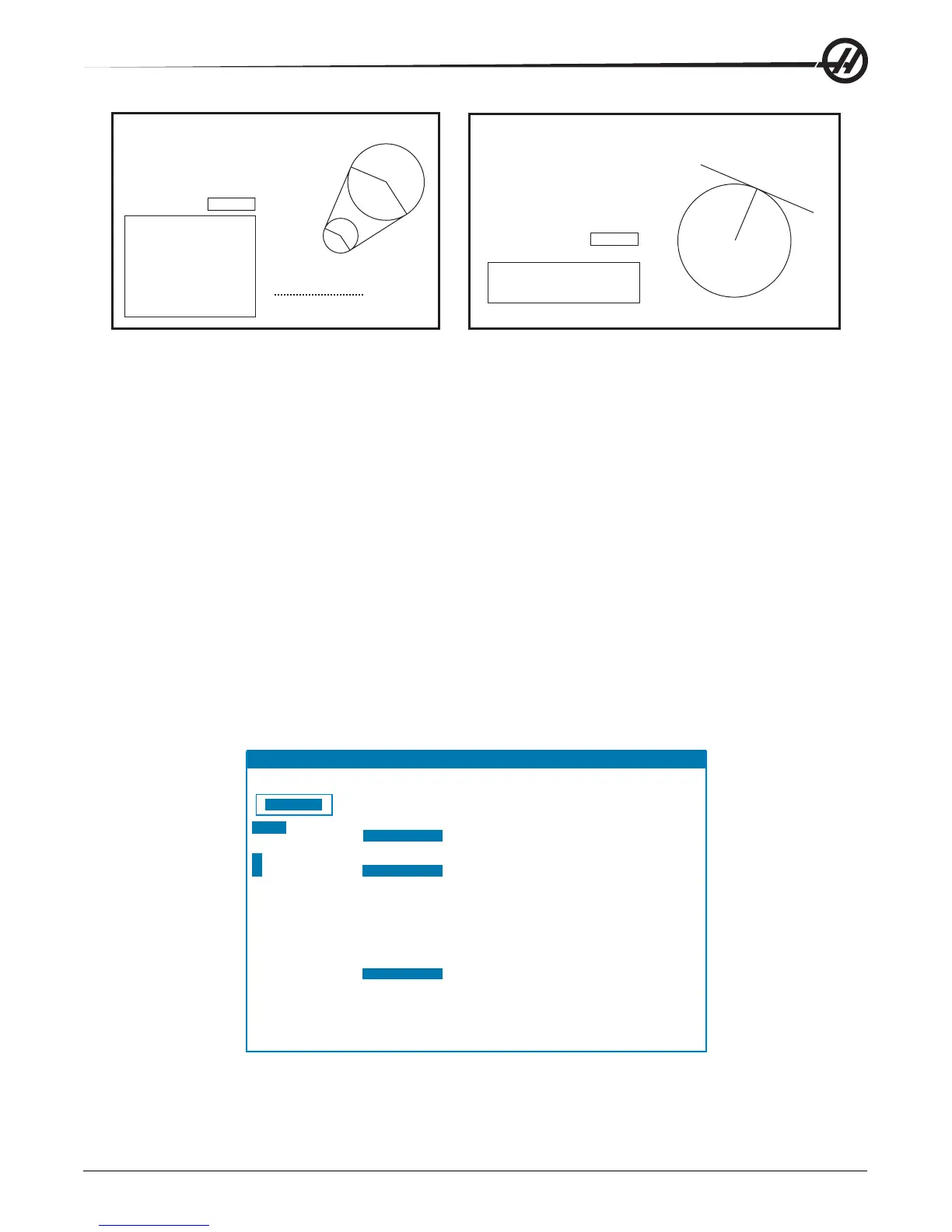

CIRCLE-CIRCLE TANGENT

CIRCLE1 X

CIRCLE1 Y

RADIUS 1

CIRCLE2 X

CIRCLE2 Y

RADIUS 2

TANGT A X

Y

TANGT B X

Y

TANGT C X

Y

TANGT D X

Y

5.0000

6.0000

4.0000

0.0000

0.0000

2.0000

1.3738

7.6885

7.3147

2.7378

-1.8131

0.8442

1.1573

-1.6311

a

b

c

d

Type: STRAIGHT

Use F and T to form G-code.

F1 for alternate solution

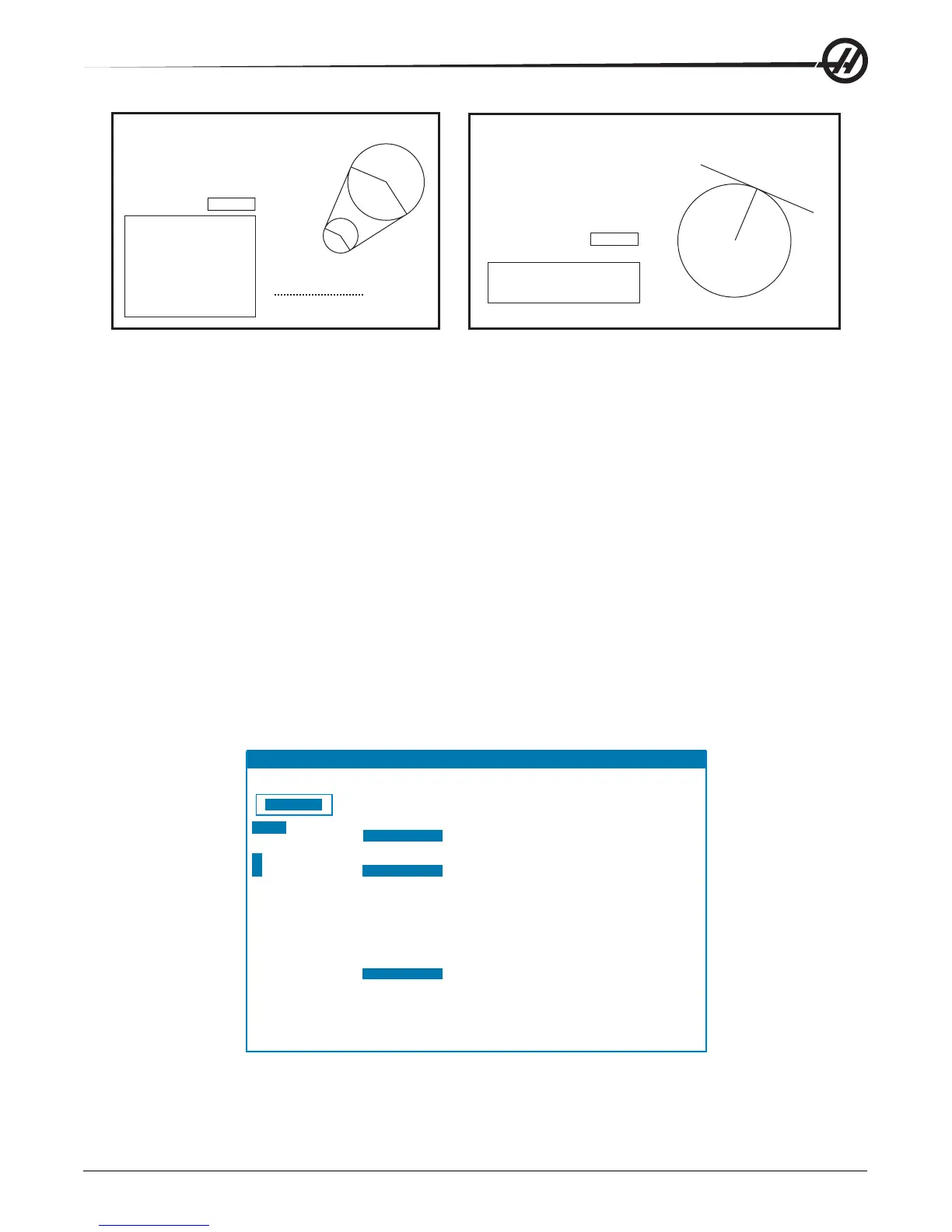

CIRCLE-LINE TANGENT

POINT A X

Y

XPOINT B

Y

POINT C X

Y

RADIUS

TANGT PT X

TANGT PT Y

5.0000

3.0000

1.0000

4.0000

0.0000

0.0000

4.1231

1.0000

4.0000

a

b

c

Circle-Circle Tangent Calculator

This feature provides the ability to determine points of intersection between two circles or points. The user

provides the location of two circles and their radii. The control then calculates all the intersection points that

are formed by lines tangent to both circles. Note: For every input condition where there are two disjointed

circles, there are up to eight intersection points. Four points are obtained from drawing straight tangents and

four points by forming cross tangents. The F1 key is used to toggle between the two diagrams. When "F" is

pressed, the control will prompt for the from and to points (A, B, C, etc.) that specify a segment of the diagram.

If the segment is an arc, the control will also prompt for C or W (CW or CCW). Sample G code is then dis-

played at the bottom of the screen. When "T" is entered, the previous to point becomes the new from point and

the control prompts for a new to point. To enter the solution (line of code), switch to MDI or Edit and press F3,

as the G-code is already on the input line.

Milling/Tapping Help

The Milling/Tapping Help page will help you solve equations relating to milling and tapping. They are:

1. SFM (Surface Feet per Minute) = (CUTTER DIAMETER IN.) * RPM * 3.14159 / 12

2. (FEED IN./MIN.) = RPM / (THREAD PITCH)

3. (CHIP LOAD IN.) = (FEED IN./MIN.) / RPM / #FLUTES

Enter all but one of the values and the control will compute the remaining value. Note that the RPM value for

the first two equations are the same entry.

CALCULATOR

PGM F0.

ACTF0.

PGM S0

CMD S0

ACT S0

PGM F0.

ACT

F0.

PGM

S0

CMD

S0

ACT

S0

MILLING

TAPPING

THREADS 3. 0000 /IN

RPM40

13. 3333 IN/MINFEED

THREADS 3. 0000 /IN

RPM

40

13.

3333 IN/MINFEED

CUTTER DIA 0. 5000 IN

SURFACE SPEED 5. 0000 FT/MIN RECOMMENDED

38

FLUTES4

FEED 6. 0000 IN/MIN

0. 0365 IN RECOMMENDED

MATERIAL LOW CARBON UNALLOYED STEEL

TOOL TYPE CARBIDE

CUT WIDTH 2. 0000 IN

CUT DEPTH 0. 0500 IN REQUIRED POWER

RPM

CHIP LOAD

CUTTER DIA 0. 5000 IN

SURFACE

SPEED 5. 0000 FT/MIN RECOMMENDED

38

FLUTES

4

FEED

6. 0000 IN/MIN

0.

0365 IN RECOMMENDED

MATERIAL

LOW CARBON UNALLOYED STEEL

TOOL

TYPE CARBIDE

CUT

WIDTH 2. 0000 IN

CUT

DEPTH 0. 0500 IN REQUIRED POWER

RPM

CHIP

LOAD

LOAD

+-*/

HELP (MEM) O00000 N00000000

0.000000000

(MACHINE)

0.0000 in

0.0000 in

3.5179 inZ

X

Y

(MACHINE)

0.0000

in

0.0000

in

3.5179

in

X

Y

Z

Note: When metric units are selected, the units displayed change to millimeters, threads per mm, mm per

minute, and meters, respectively.

Loading...

Loading...