Operation

54

96-8000 rev R June 2007

PROGRAMABLE COOLANT

DO NOT ADJUST NOZZLE

BY HAND

DO NOT ADJUST NOZZLE

BY HAND

Home

H01

H20

Warning

Do not rotate the coolant spigot by hand. Serious motor damage will

occur.

Minimum Oil Machining (MOM)

Minimum Oil Machining (MOM) is an automated process, which can operate in two modes: lubricating a tool during

a canned cycle operation (Canned Mode), or as an alternative to flood coolant (MOM Mode). MOM Mode is similar

to Near Dry Machining (NDM) and Minimum Quantity Lubrication (MQL), and can produce dry or near dry chips.

Canned Mode is used to lubricate taps, drills, or boring bars during Canned Cycles. Parameters 696-699 and M

codes 101-103 are used with this option, refer to these sections for further information. MOM can be setup and

tested by using the MOM page of the CURNT COMDS display. The MOM page displays the following information:

MOM Override: None - Use M-Codes to operate MOM.

Ignore - Ignore MOM M-Codes.

Canned Cycle - Act as if M101 is always active (squirt per G-Code).

Manual - Turns MOM Mode on (squirt every time between squirts)

Squirt On Time Canned Cycle (M101 Ix.xxx): 0.100 sec (Tapping)

Squirt On Time MOM (M102 Ix.xxx): 0.050 sec

Time Between Squirts MOM (M102 Jx.xxx): 2.000 sec (Time between squirts)

Pressing display page function keys will perform specific operations useful in setting up the MOM system:

F1 - Squirt once

F2 - Toggle MOM On and Off

F3 - Toggle Purge On and Off

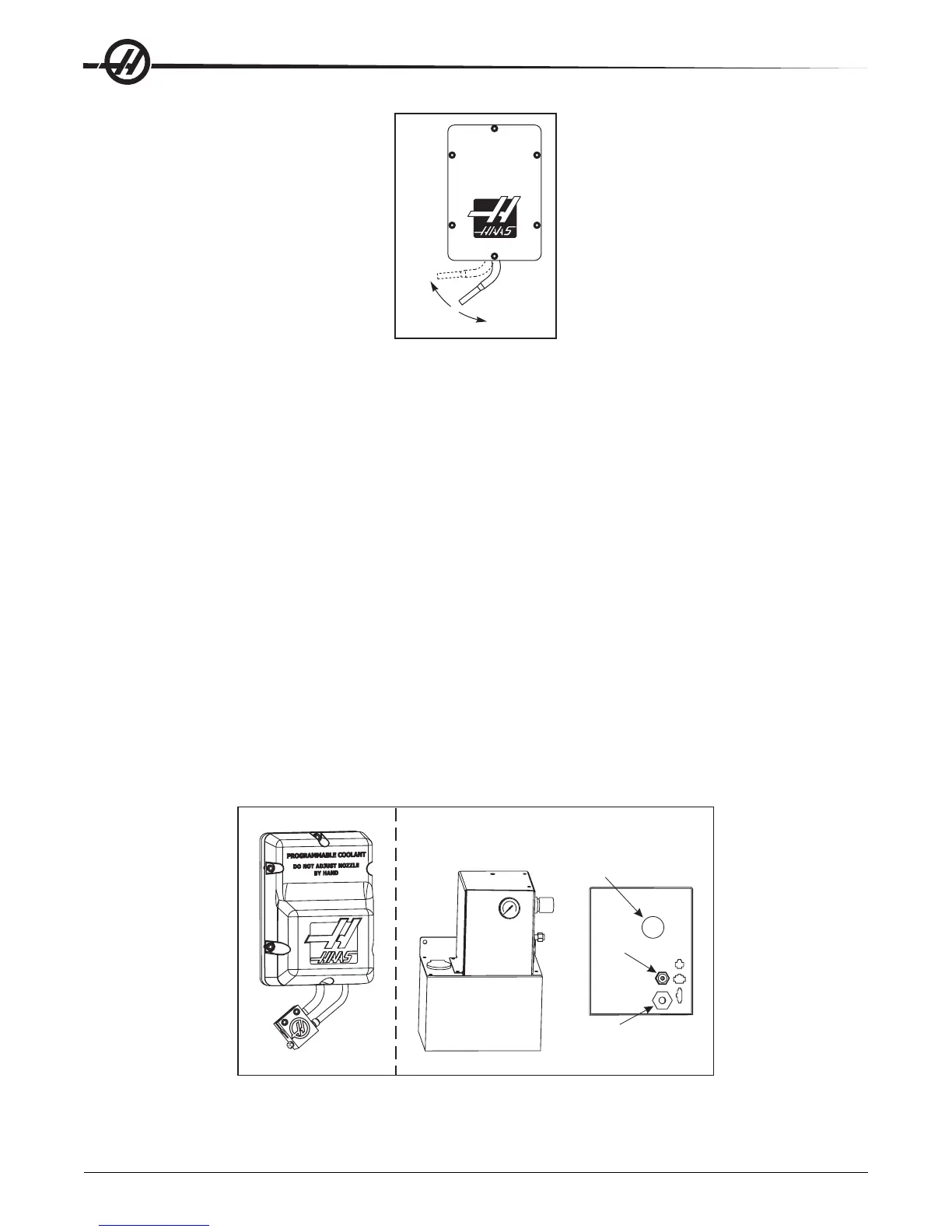

Delivery System

INSIDE MACHINE

ON BACK

Oil

Pressure

Regulator

Air Supply In

Pump

Fluid

Reservoir

Loading...

Loading...