254 ISO Programming

4.17 Contour-Based Turning Cycles

The MANUALplus uses the tool definition to distinguish between

external and internal machining.

Parameters

B Contour calculation

0: Automatic

1: Tool to the left (G41)

2: Tool to the right (G42)

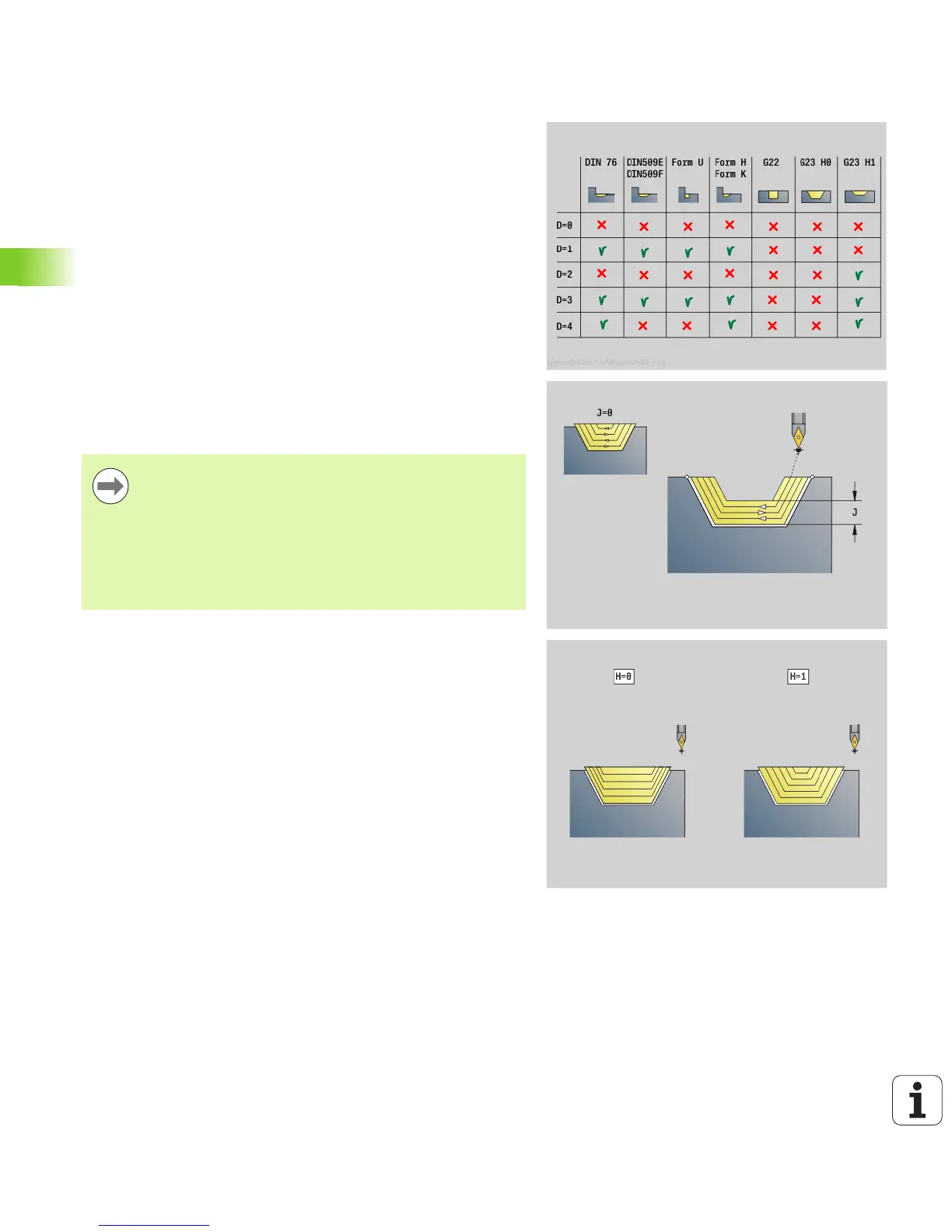

D Omit elements (see figure)

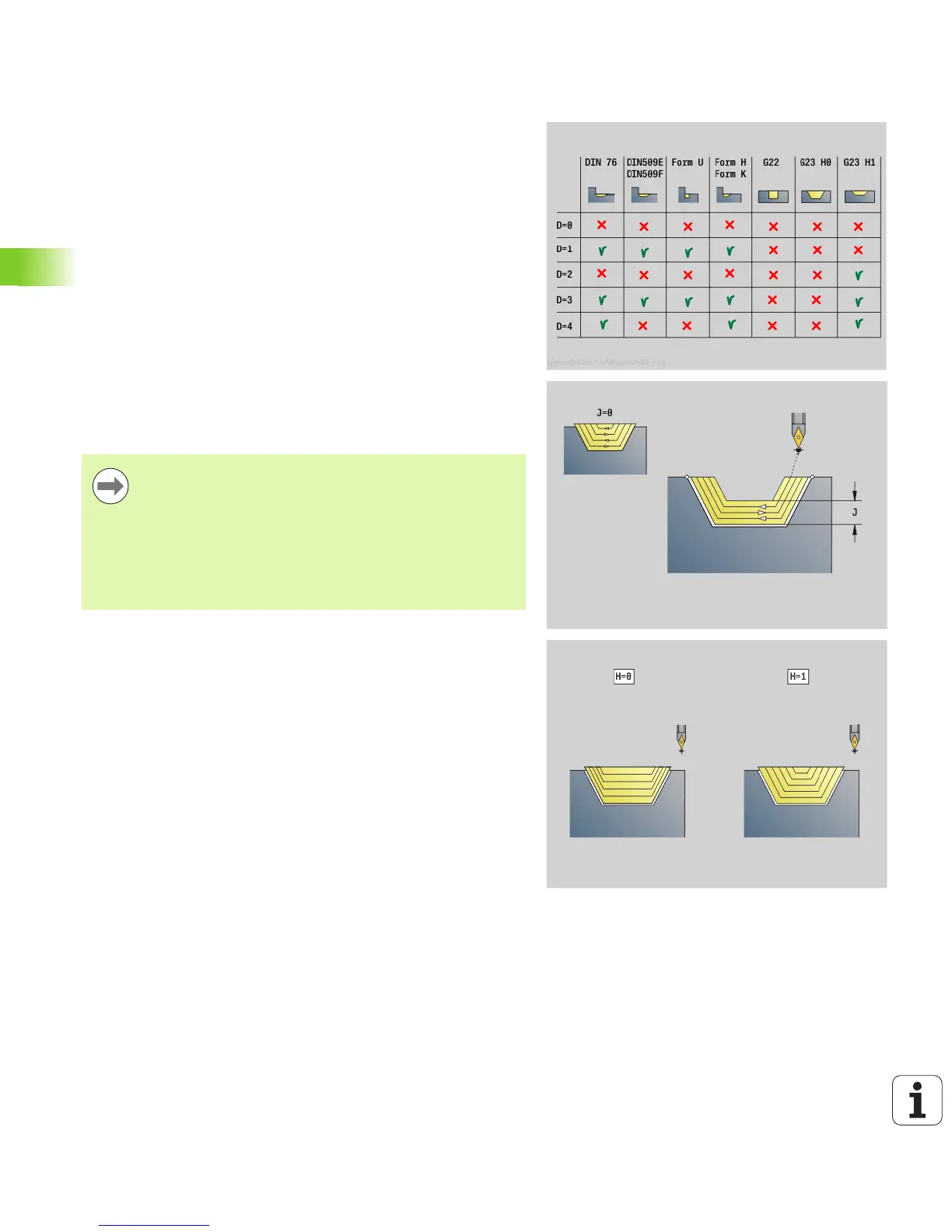

J Workpiece blank oversize (radius value)—active only if no

blank has been defined.

H Contour-parallel—Type of cutting paths:

0: Constant machining depth

1: Equidistant cut lines

The tool radius compensation: is active.

A G57 oversize enlarges the contour (also inside

contours).

A G58 oversize

>0: Enlarges the contour

<0: Is not offset

G57/G58 oversizes are deleted after cycle end.

Cycle run

1 Calculates the areas to be machined and the cutting

segmentation.

2 Approaches workpiece for first pass from starting point, taking

the safety clearance into account.

3 Executes the first cut (roughing).

4 Approaches for the next pass and execute the next cut

(roughing) in the opposite direction.

5 Repeats 3 to 4 until the complete area has been machined.

6 If required, repeats 2 to 5 until all areas have been machined.

7 Retracts as programmed in Q.

Loading...

Loading...