324 ISO Programming

4.26 Milling Cycles

Area milling, face G797

Depending on Q, G797 mills surfaces, a polygon, or the figure defined

in the command following G797.

Parameters

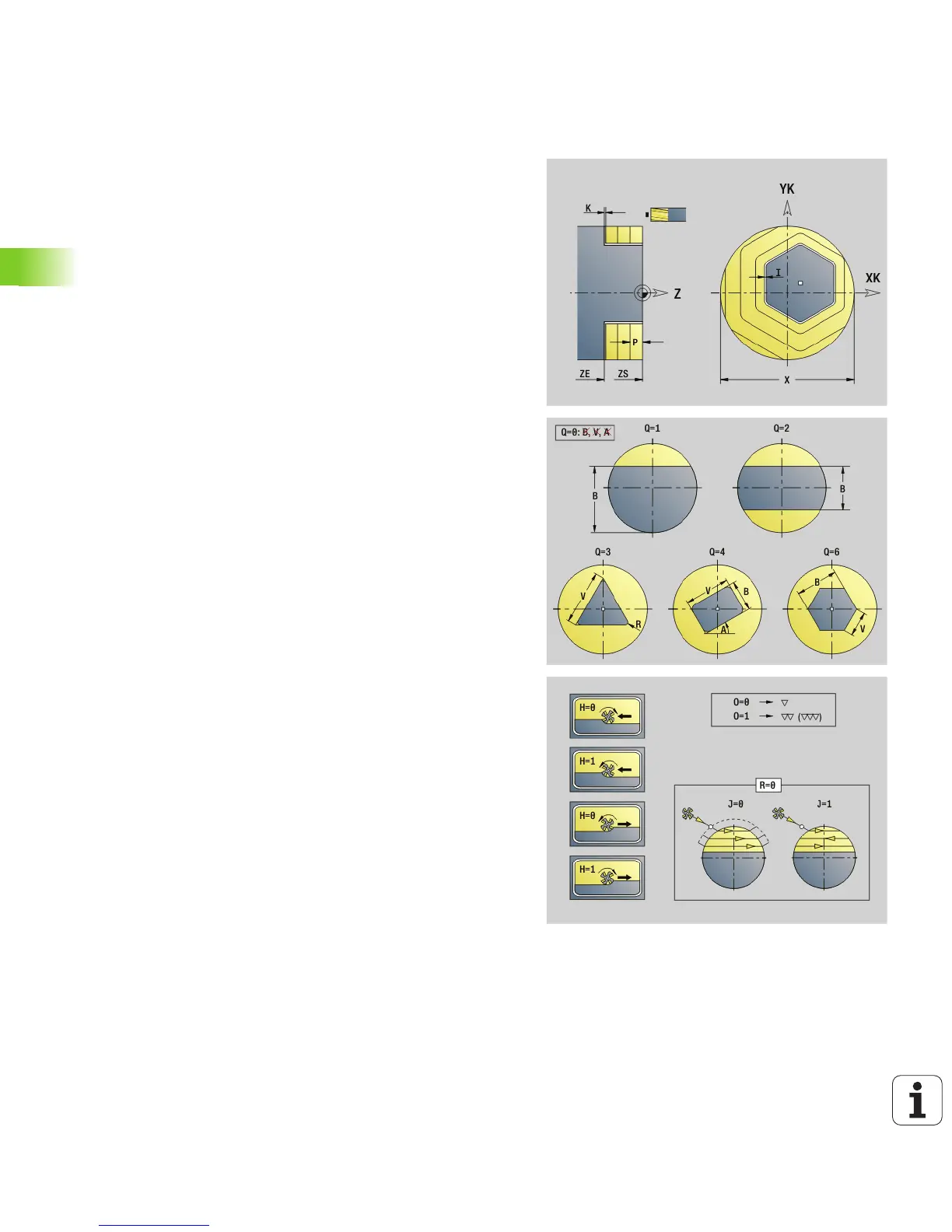

X Limit diameter

ZS Milling top edge

ZE Milling floor

B Width across flats (omit for Q=0): B defines the remaining

material. For an even number of surfaces, you can program B

as an alternative to V.

Q=1: B=Residual depth

Q>=2: B=Width across flats

V Edge length (omitted for Q=0)

R Chamfer/rounding

A Inclination angle (reference: see help graphic) —omitted for

Q=0

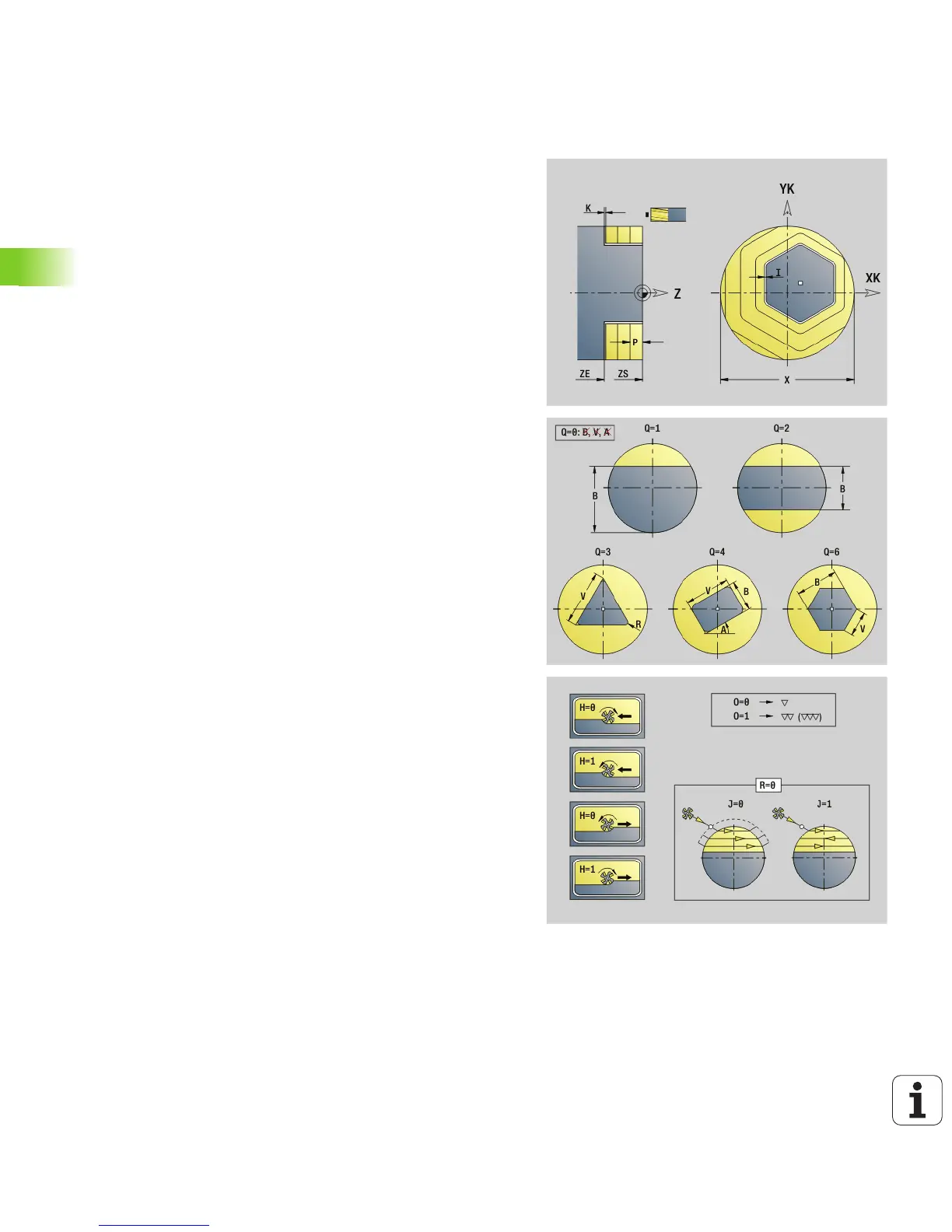

Q Number of surfaces (default: 0): Range 0 <= Q <= 127

Q=0: G797 is followed by a figure definition (G301 to G307,

G80) or a closed contour definition (G100 to G103, G80)

Q=1: One surface

Q=2: Two surfaces offset by 180°

Q=3: Triangle

Q=4: Rectangle, square

Q>4: Polygon

P Maximum approach (default: total depth in one infeed)

U Overlap factor (default: 0.5): Minimum overlap of milling paths

= U*milling diameter

I Contour-parallel oversize

K Oversize in Z

F Approach feed (infeed rate)

E Reduced feed rate for circular elements (default: current feed

rate)

H Cutting direction (default: 0): The cutting direction can be

changed with H and the direction of tool rotation (see help

graphic)

0: Up-cut milling

1: Climb milling

Loading...

Loading...