262 ISO Programming

4.17 Contour-Based Turning Cycles

Finish contour G890

G890 finishes the defined contour area in one pass. The reference to

the contour to be machined can be transferred in the cycle

parameters, or the contour can be defined directly after the cycle call

(see “Working with contour-based cycles” on page 246). The contour

to be machined may contain various valleys. If required, the area to be

machined is divided into several sections.

Parameters

ID Auxiliary contour—ID number of the contour to be machined

NS Starting block number (beginning of contour section)

NE End block number (end of contour section)

NE not programmed: The contour element NS is machined

in the direction of contour definition.

NS=NE programmed: The contour element NS is machined

opposite to the direction of contour definition.

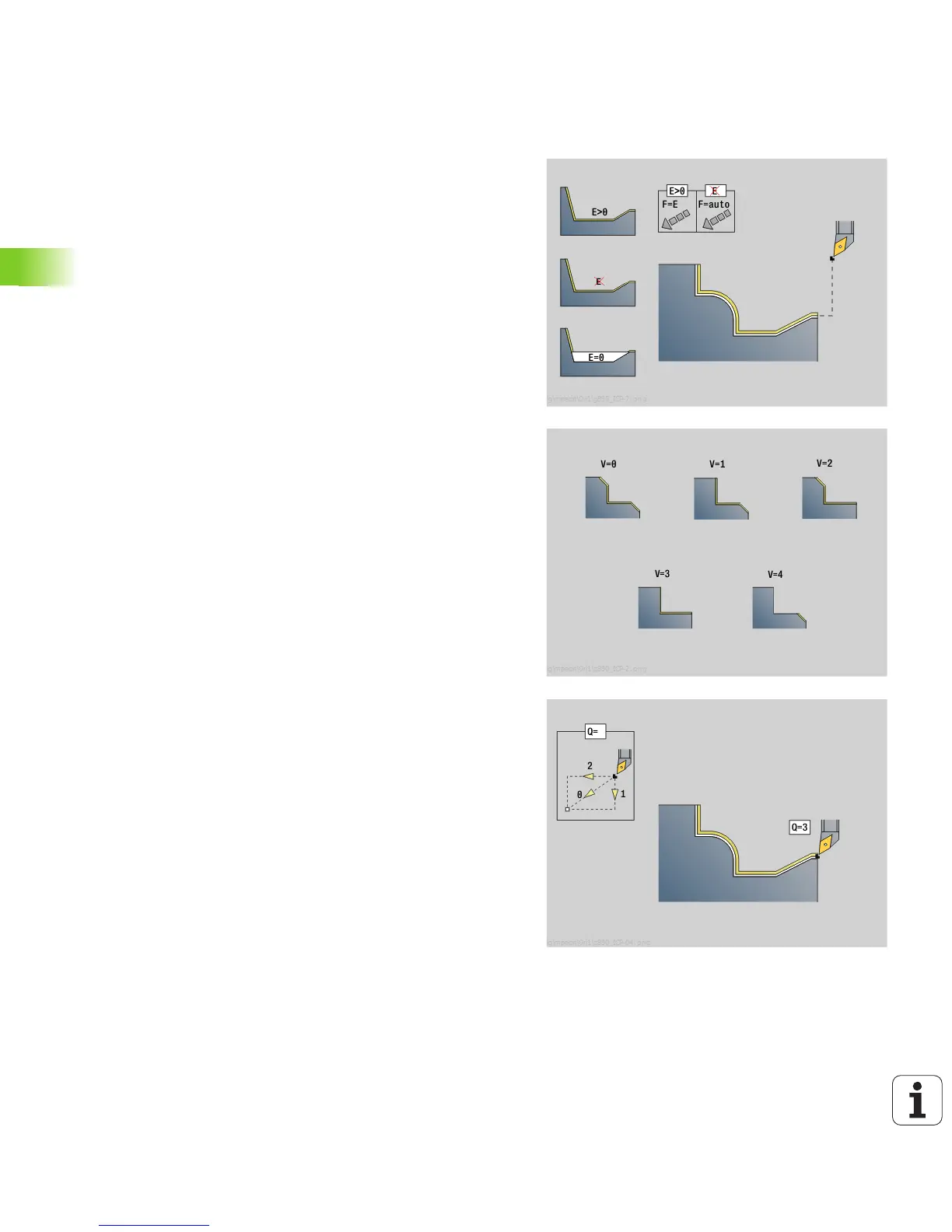

E Plunging behavior

E=0: Descending contours are not machined.

E>0: Plunging feed rate

No input: Descending contours are machined at

programmed feed rate

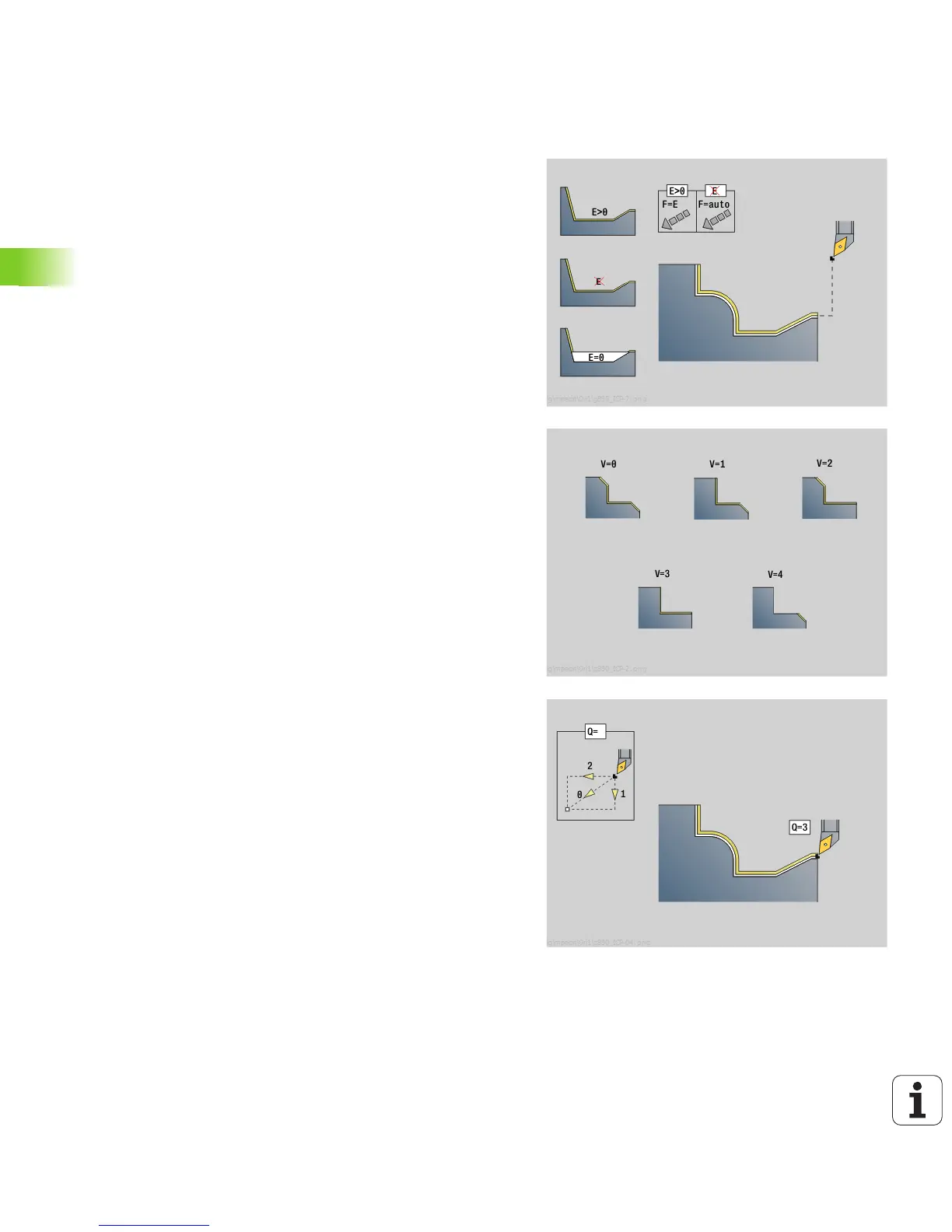

V Identifier start/end (default: 0) A chamfer/rounding arc is

machined:

0: At start and end

1: At the start

2: At the end

3: No machining

4: Chamfer/rounding arc is machined—not the basic

element (prerequisite: Contour section with one element)

Q Type of approach (default: 0)

0: Automatic selection—the MANUALplus checks:

Diagonal approach

First X, then Z direction

Equidistant around the barrier

Omission of the first contour elements if the starting

position is inaccessible

1: First X, then Z direction

2: First Z, then X direction

3: No approach—tool is located near the starting point of

the contour area.

Loading...

Loading...