HEIDENHAIN MANUALplus 620 299

4.22 Drilling and Boring Cycles

Deep-hole drilling G74

G74 is used for axial and radial holes in several stages using driven or

stationary tools.

Example: G74

. . .

N1 M5

N2 T4 G197 S1000 G195 F0.2 M103

N3 M14

N4 G110 C0

N5 G0 X80 Z2

N6 G745 XK0 YK0 Z2 K80 Wi90 Q4 V2

N7 G74 Z-40 R2 P12 I2 B0 J8 [drilling]

N8 M15

. . .

Parameters

ID Drilling contour—Name of the hole definition

NS Block number of contour

Reference to the contour of the hole (G49-Geo, G300-Geo

or G310-Geo)

No input: Single hole without contour description

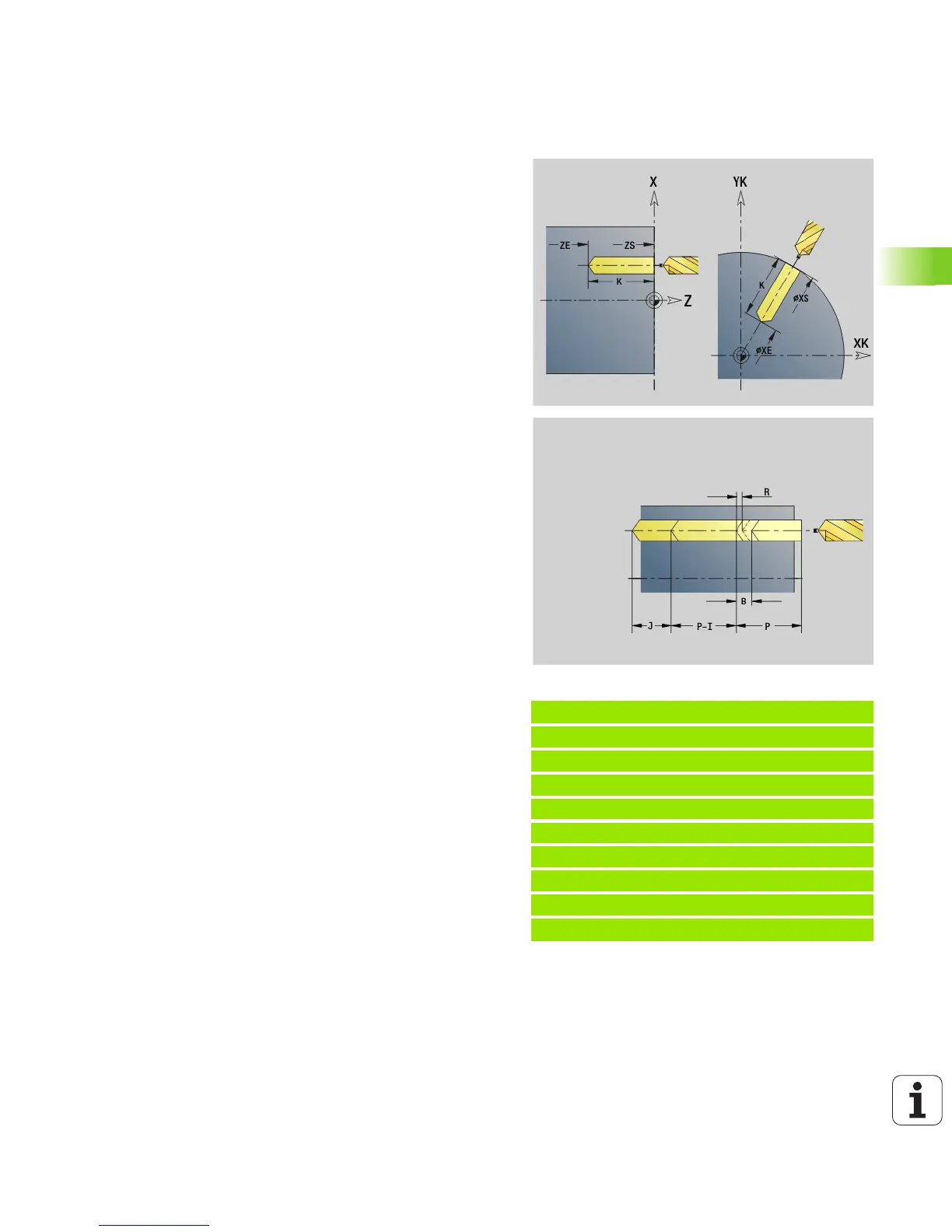

XS Starting point of axial hole (diameter value)

ZS Starting point of radial hole

XE Final point of axial hole (diameter value)

ZE Final point of radial hole

K Boring depth (hole depth) (alternative to XE/ZE)

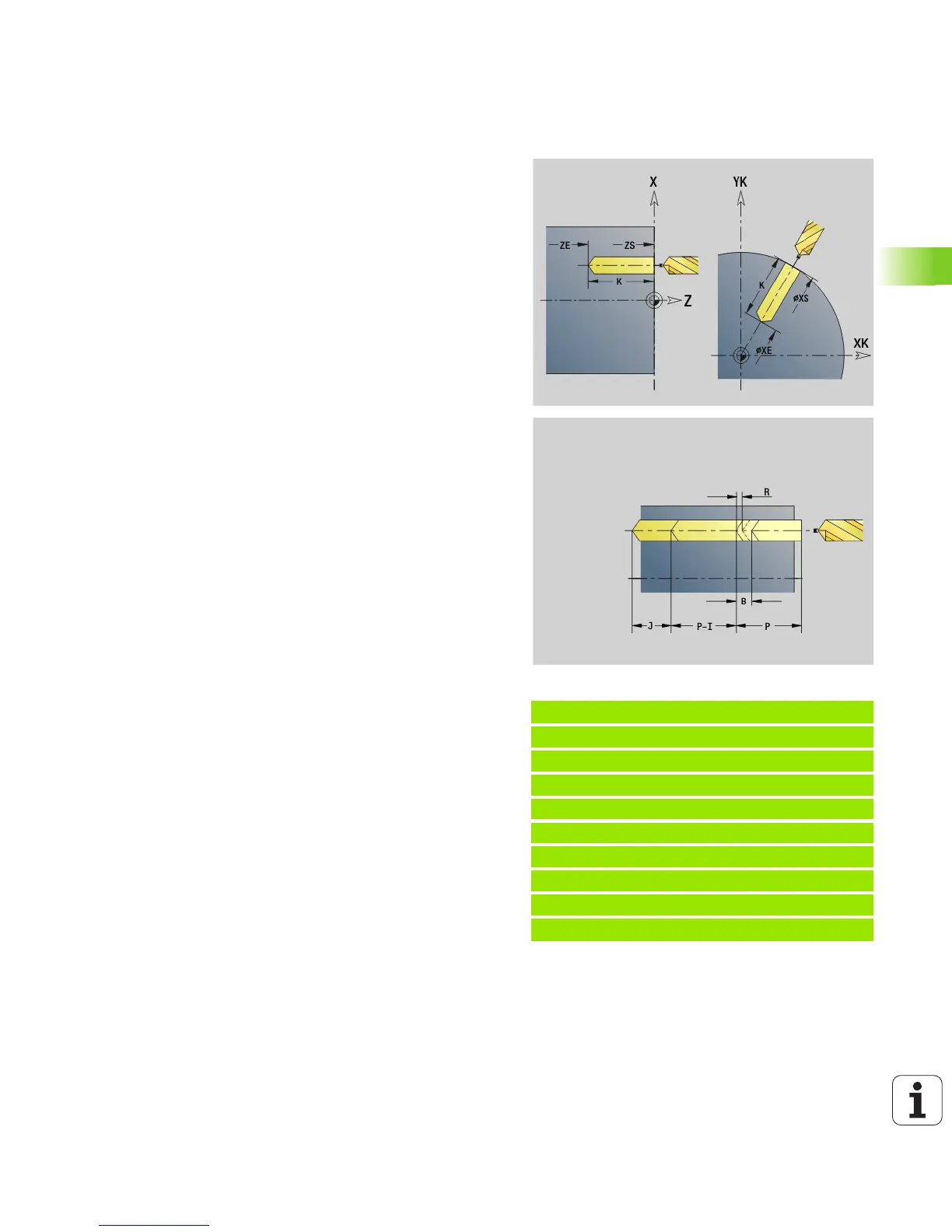

P 1st hole depth (1st drilling depth)

I Reduction value (default: 0)

B Retraction distance (default: to starting point of hole)

J Minimum hole depth (default: 1/10 of P)

R Safety distance (inside)

A Drilling lengths—(default: 0)

V Bore (through-drilling) variant (feed rate reduction 50%)—

(default: 0)

0: No feed rate reduction

1: Feed reduction for through-drilling

2: Feed reduction for pre-drilling

3: Feed reduction for pre-drilling and through-drilling

RB Return plane (radial holes: diameter)—(default: to starting

position or to safety clearance)

E Period of dwell for chip breaking at end of hole (in seconds)—

(default: 0)

D Retraction speed and infeed within the hole (default: 0)

0: Rapid traverse

1: Feed rate

BS Start element no. (number of the first hole to be machined in

a pattern)

BE End element no. (number of the last hole to be machined in a

pattern)

H (Spindle) Brake off (default: 0)

0: Spindle brake on

1: Spindle brake off

Loading...

Loading...