HEIDENHAIN MANUALplus 620 265

4.18 Contour Definitions in the Machining Section

4.18 Contour Definitions in the

Machining Section

Cycle end / Simple contour G80

By programming G80 (with parameters), a turning contour consisting

of more than one element can be defined in one NC block. G80

(without parameters) ends a contour definition directly after a cycle.

“IC” and “KC” are used in the control to show the chamfer/rounding

cycles.

Example: G80

N1 T3 G95 F0.25 G96 S200 M3

N2 G0 X120 Z2

N3 G810 P3

N4 G80 XS60 ZS-2 XE90 ZE-50 BS3 BE-2 RC5

N5 ...

N6 G0 X85 Z2

N7 G810 P5

N8 G0 X0 Z0

N9 G1 X20

N10 G1 Z-40

N11 G80

Parameters

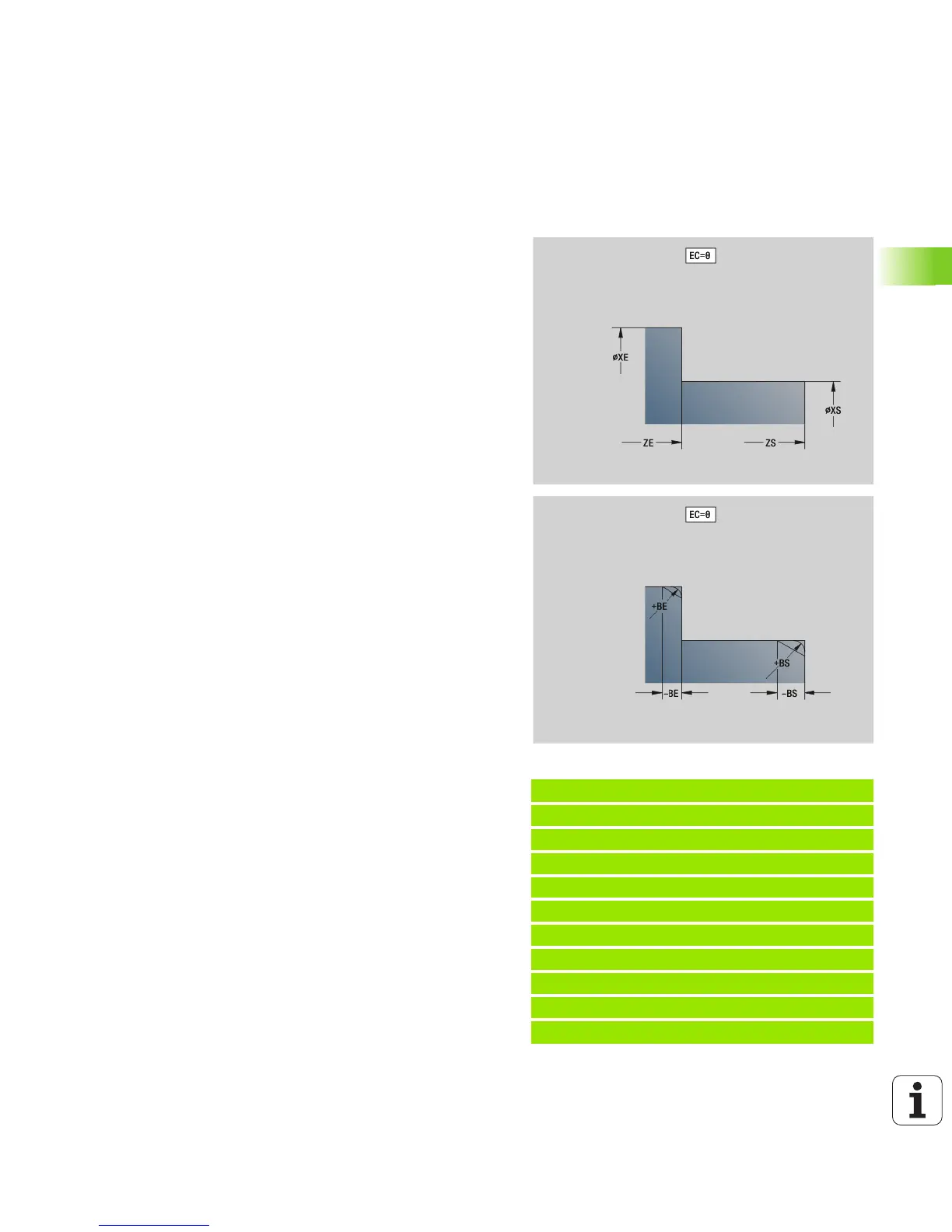

XS Starting point of contour in X (diameter value)

ZS Starting point of contour in Z

XE Contour end point in X (diameter value)

ZE Contour end point in Z

AC Angle of 1st element (range 0°<=AC<90°)

WC Angle of 2nd element (range 0°<=AC<90°)

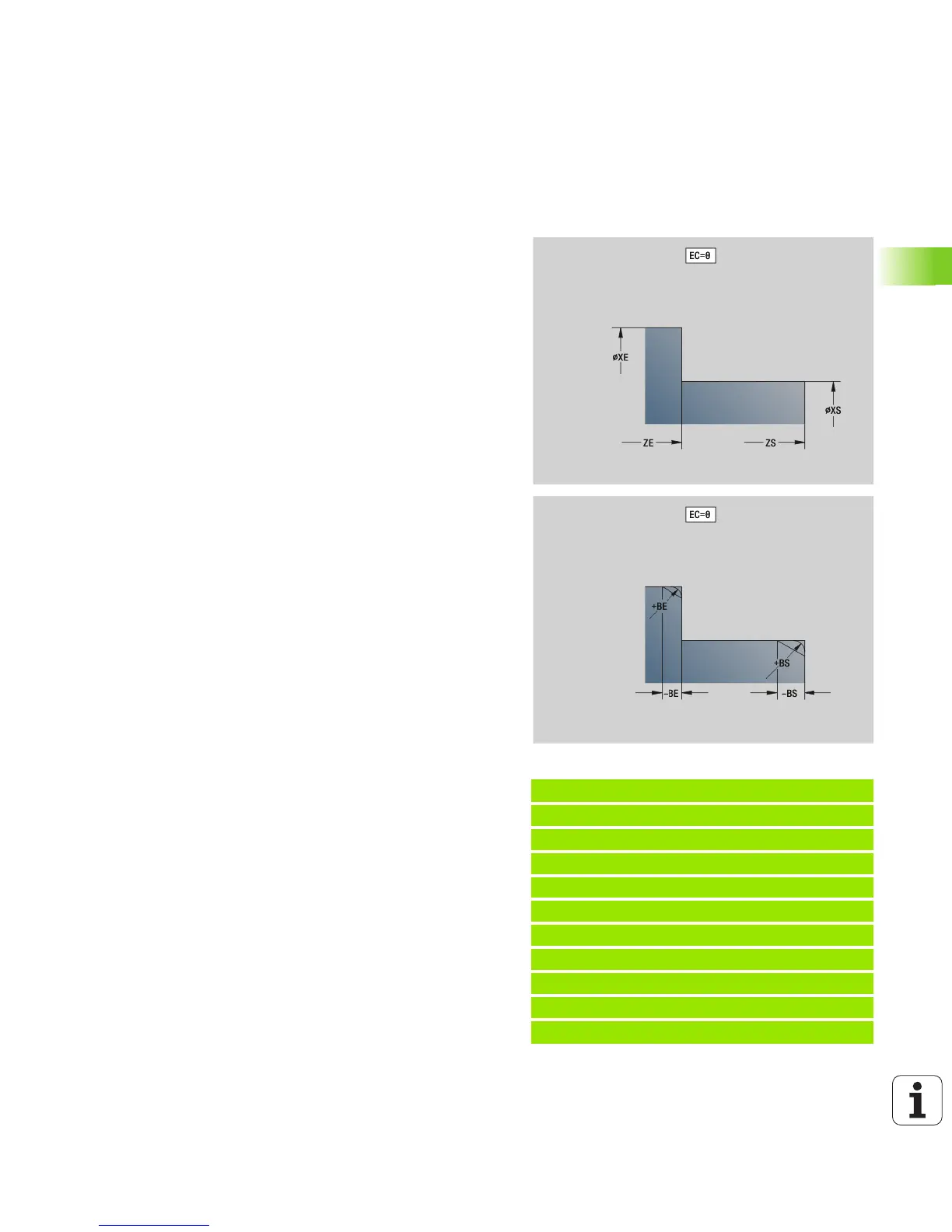

BS Chamfer/rounding arc at starting point

WS Angle for chamfer at starting point

BE Chamfer/rounding arc at end point

WE Angle for chamfer at end point

RC Radius

IC Chamfer width

KC Chamfer width

JC Execution (see cycle programming)

0: Simple contour

1: Expanded contour

EC Plunging contour

0: Rising contour

1: Plunging contour

HC Contour direction for finishing:

0: Longitudinal

1: Transverse

Loading...

Loading...