HEIDENHAIN MANUALplus 620 277

4.19 Thread Cycles

The cycle calculates the thread from the thread end point, thread

depth and the tool position.

First infeed = Remainder of the division of thread depth/cutting depth.

Transverse thread: Use G31 with contour definition for cutting

transverse threads.

Example: G32

. . .

N1 T4 G97 S800 M3

N2 G0 X16 Z4

N3 G32 X16 Z-29 F1.5 [thread]

. . .

Parameters

C Starting angle (thread start is defined with respect to

rotationally nonsymmetrical contour elements)—(default: 0)

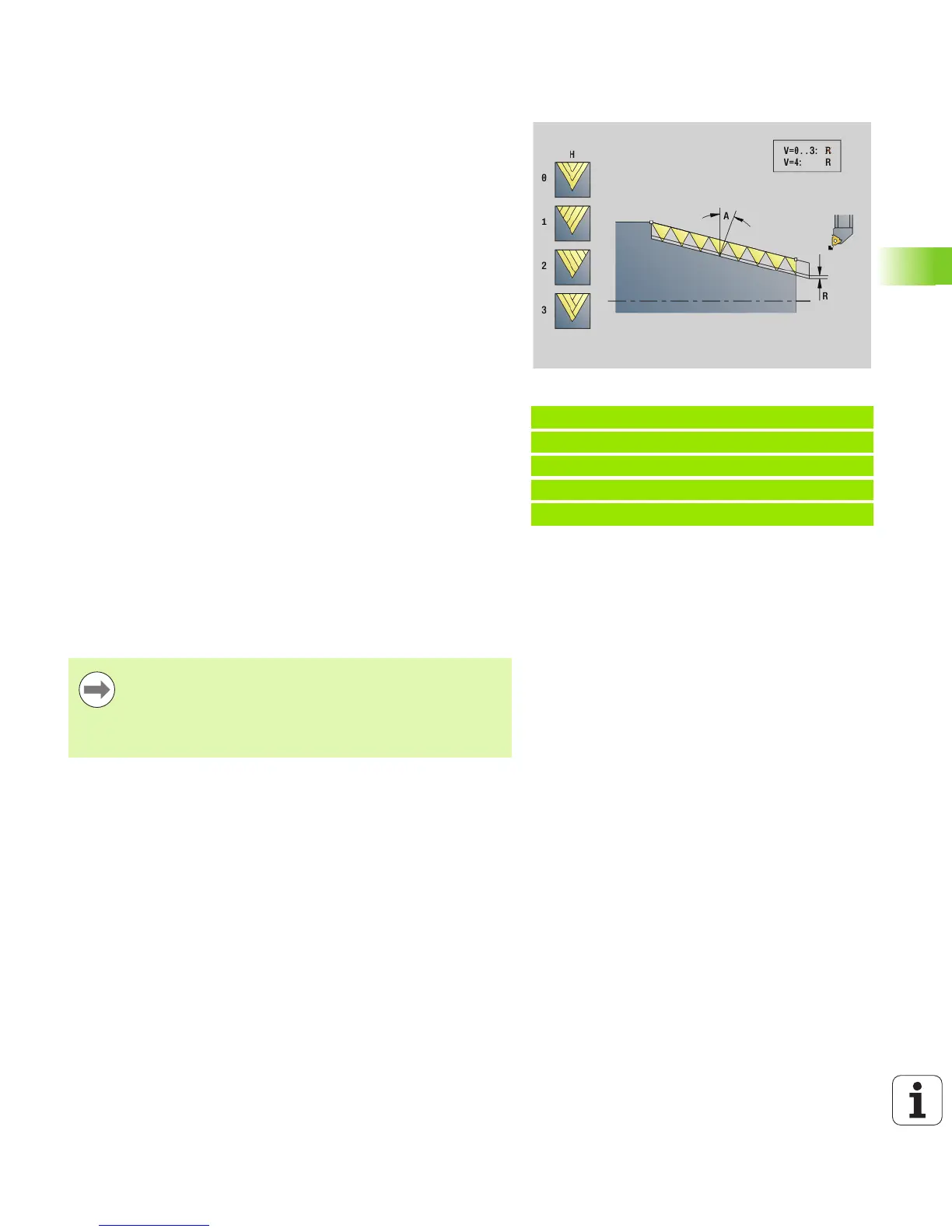

A Approach angle (angle of infeed) (default: 30°)

R Remainder cuts (default: 0)

0: The last cut is divided into four partial cuts: 1/2, 1/4, 1/8

and 1/8.

1: W/o remaining cutting (without distribution of remaining

cuts)

E Variable pitch (no effect at present)

Q Number of air cuts after the last cut (for reducing the cutting

pressure in the thread base)—(default: 0)

D Number of thread turns for multi-start thread

J Reference direction:

No input: The reference direction is determined from the

first contour element.

J=0: Longitudinal thread

J=1: Transverse thread

Cycle stop—the MANUALplus retracts the tool from the

thread groove and then stops all tool movements. (Lift-

off distance: OEM configuration parameter:

cfgGlobalPrperties-threadliftoff)

Feed rate override is not effective.

Cycle run

1 Calculates the number of cutting passes.

2 Executes a thread cut.

3 Returns at rapid traverse and approaches for next pass.

4 Repeats 2 to 3 until the complete thread has been cut.

5 Executes air cuts.

6 Returns to starting point.

Loading...

Loading...