328 ISO Programming

4.26 Milling Cycles

G840—Calculating hole positions

“G840 A1 ..” calculates the hole positions and stores them at the

reference specified in “NF.” Program only the parameters given in the

following table.

See also:

G840—Fundamentals: Page 327

G840— Milling: Page 330

Parameters—Calculating hole positions

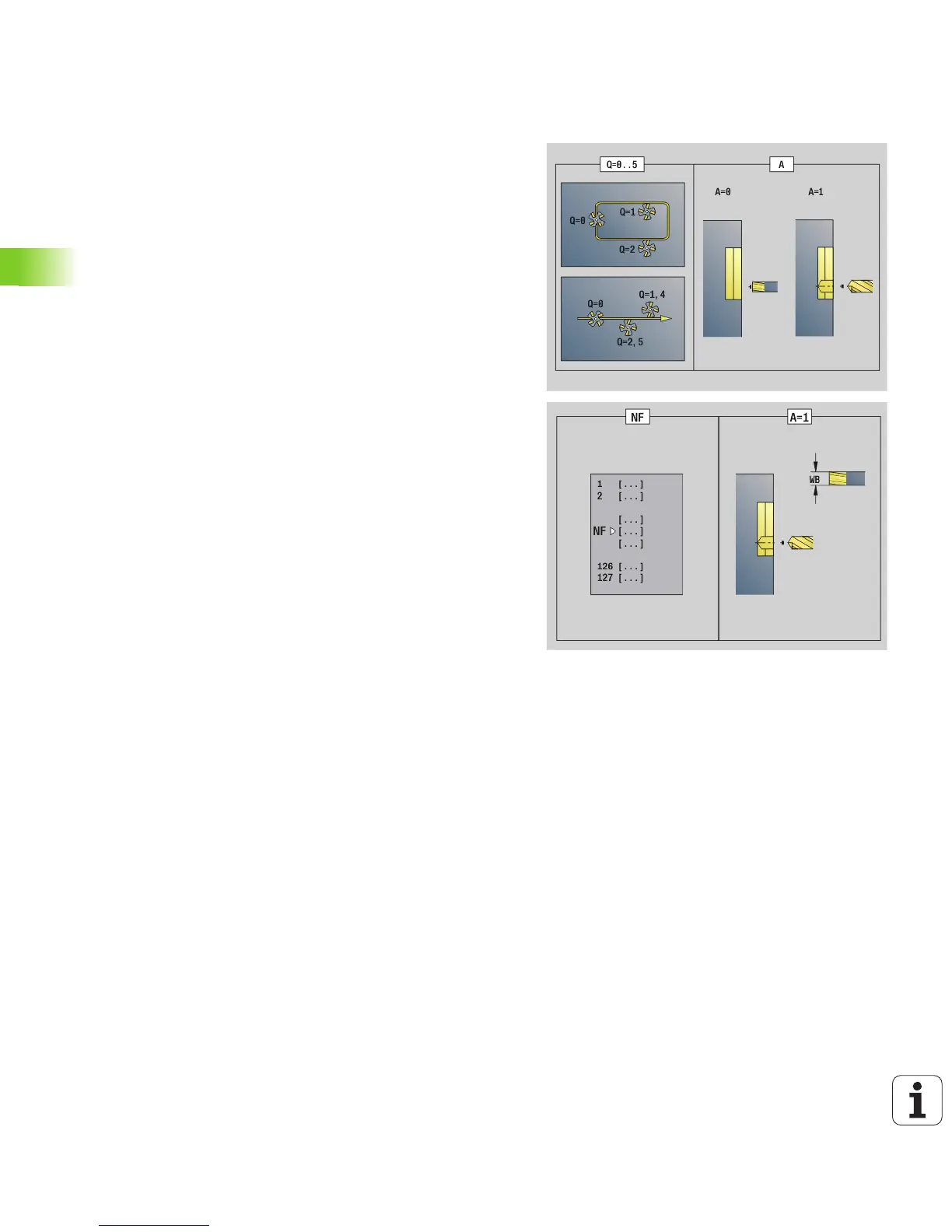

Q Cycle type (= milling location)

Open contour. If there is any overlapping, Q defines

whether the first section (as of starting point) or the entire

contour is to be machined.

Q=0: Center of milling cutter on the contour (hole

position = starting point)

Q=1: Machining at the left of the contour. If there is

overlapping, only the first section of the contour is

machined.

Q=2: Machining at the right of the contour. If there is

overlapping, only the first section of the contour is

machined.

Q=3: Not allowed

Q=4: Machining at the left of the contour. If there is

overlapping, the entire contour is machined.

Q=5: Machining at the right of the contour. If there is

overlapping, the entire contour is machined.

Closed contours

Q=0: Center of milling cutter on the contour (hole

position = starting point)

Q=1: Inside milling

Q=2: Outside milling

Q=3 to 5: Not allowed

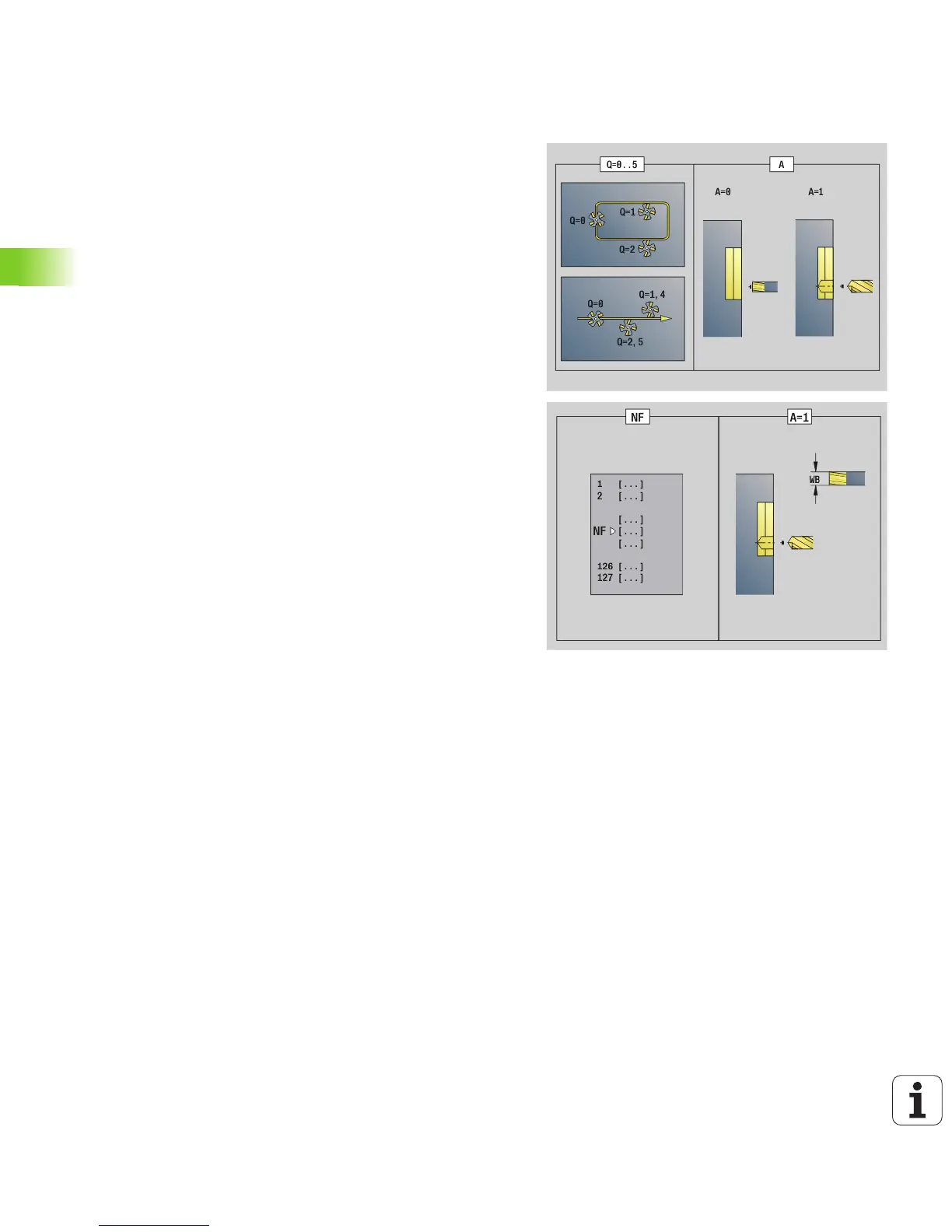

ID Milling contour—name of the contour to be milled

NS Contour start block number—beginning of contour section

Figures: Block number of the figure

Free closed contour: First contour element (not starting

point)

Open contour: First contour element (not starting point)

NE Contour end block number—end of contour section

Figures, free closed contour: No input

Open contour: last contour element

Contour consists of one element:

No input: Machining in contour direction

NS=NE programmed: Machining against the contour

direction

Loading...

Loading...