342 ISO Programming

4.26 Milling Cycles

You can change the milling direction with the cutting direction H, the

machining direction Q and the direction of tool rotation (see following

table). Program only the parameters given in the following table.

For the machining direction Q=1 (from the outside toward

the inside), please note:

The contour must start with a linear element.

If the starting element is < WB, WB is reduced to the

length of the starting element.

The length of the starting element must not be less than

1.5 times the diameter of the milling cutter.

Cycle run

1 Starting position (X, Z, C) is the position before the cycle begins.

2 Calculates the number of cuts (infeeds to the milling planes,

infeeds in the milling depths) and the plunging positions and

paths for reciprocating or helical plunges.

3 Approaches to safety clearance and, depending on O, feeds to

the first milling depth or approaches helically or on a

reciprocating path.

4 Mills a plane.

5 Retracts by the safety clearance, returns and cuts to the next

milling depth.

6 Repeat steps 4 and 5 until the complete surface is milled.

7 Returns to retraction plane RB.

Pocket milling, roughing G845

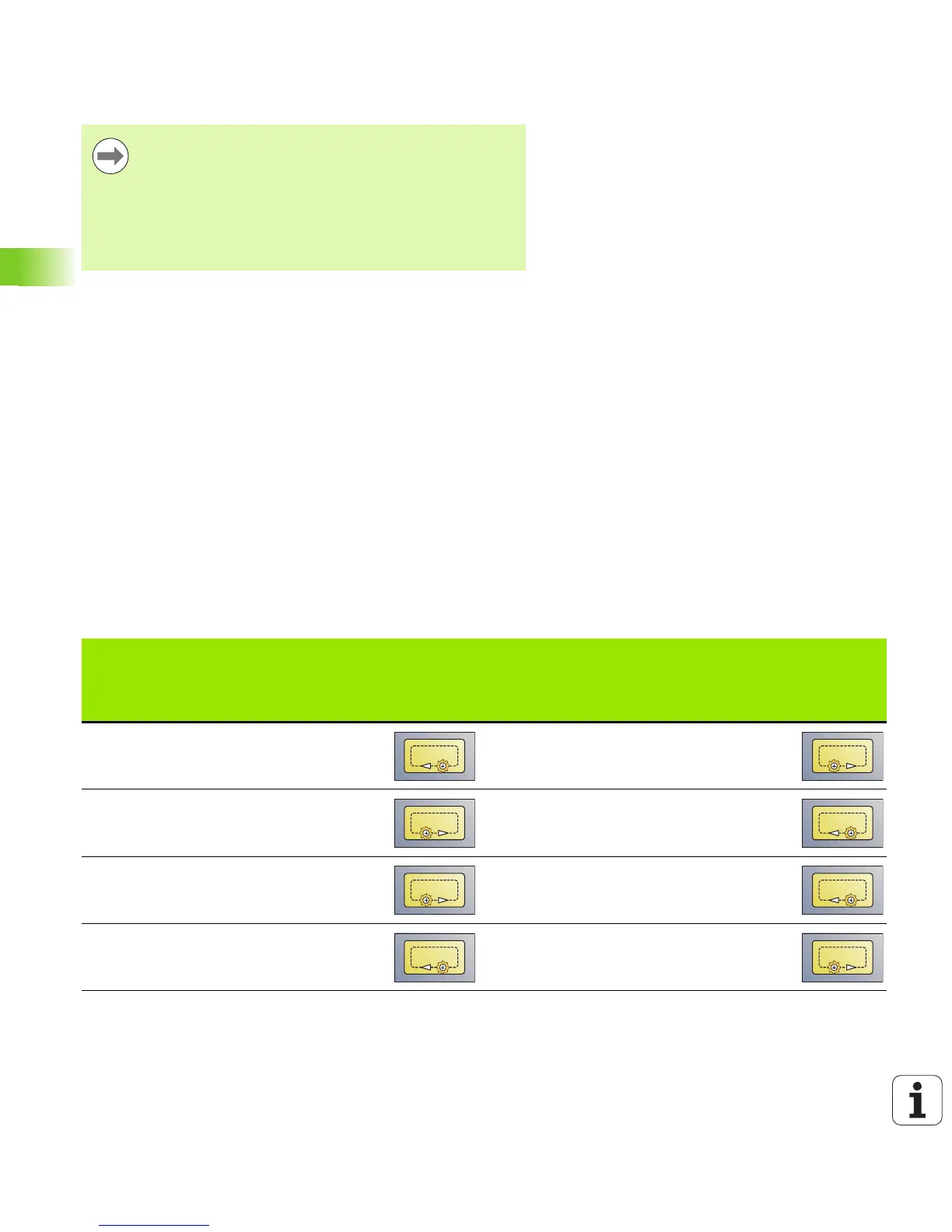

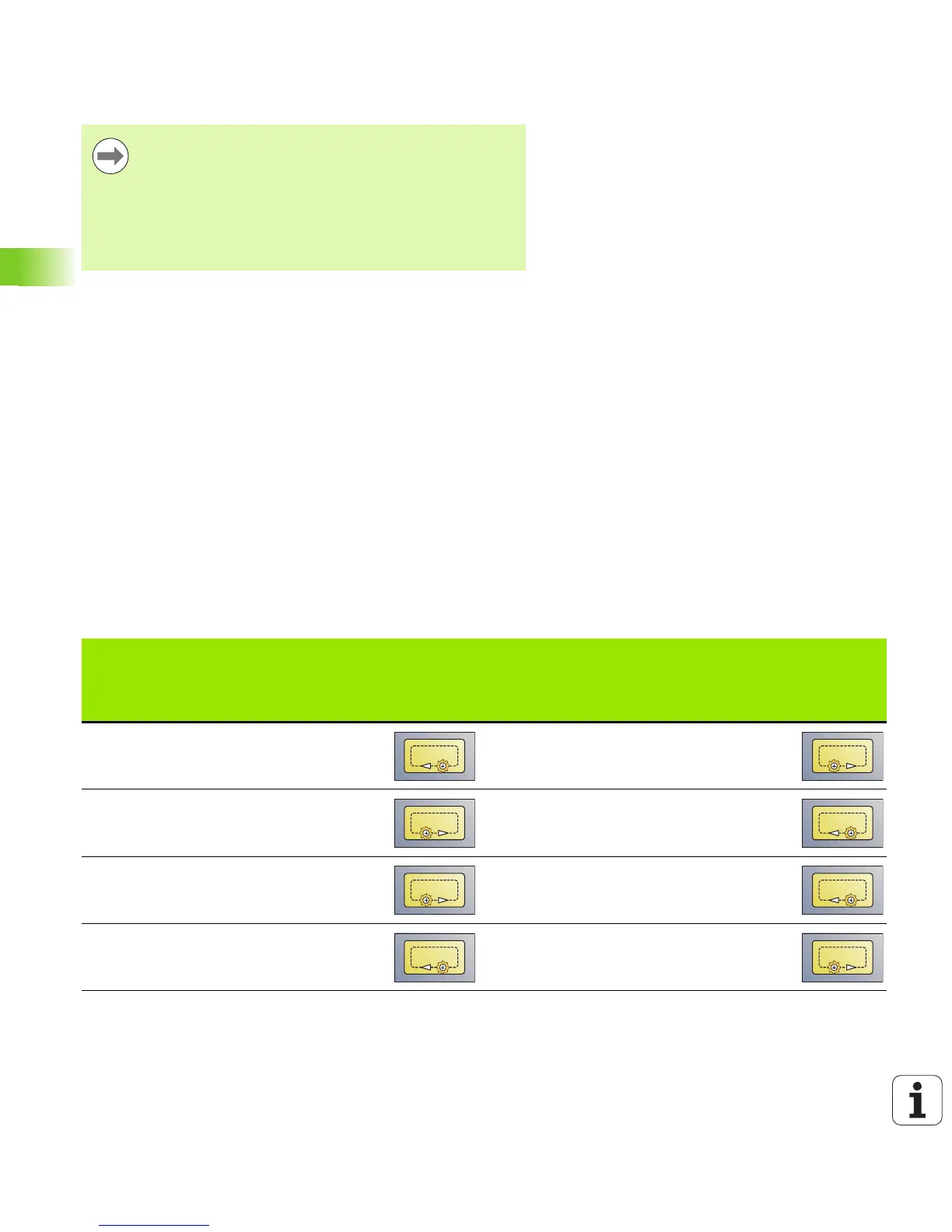

Cutting

direction

Machining

direction

Direction

of tool

rotation

Execution

Cutting

direction

Machining

direction

Direction

of tool

rotation

Execution

Up-cut milling

(H=0)

From inside

(Q=0)

Mx03 Climb milling

(H=1)

From inside

(Q=0)

Mx03

Up-cut milling

(H=0)

From inside

(Q=0)

Mx04 Climb milling

(H=1)

From inside

(Q=0)

Mx04

Up-cut milling

(H=0)

From outside

(Q=1)

Mx03 Climb milling

(H=1)

From outside

(Q=1)

Mx03

Up-cut milling

(H=0)

From outside

(Q=1)

Mx04 Climb milling

(H=1)

From outside

(Q=1)

Mx04

Loading...

Loading...