HEIDENHAIN MANUALplus 620 375

4.35 G Functions from Previous Controls

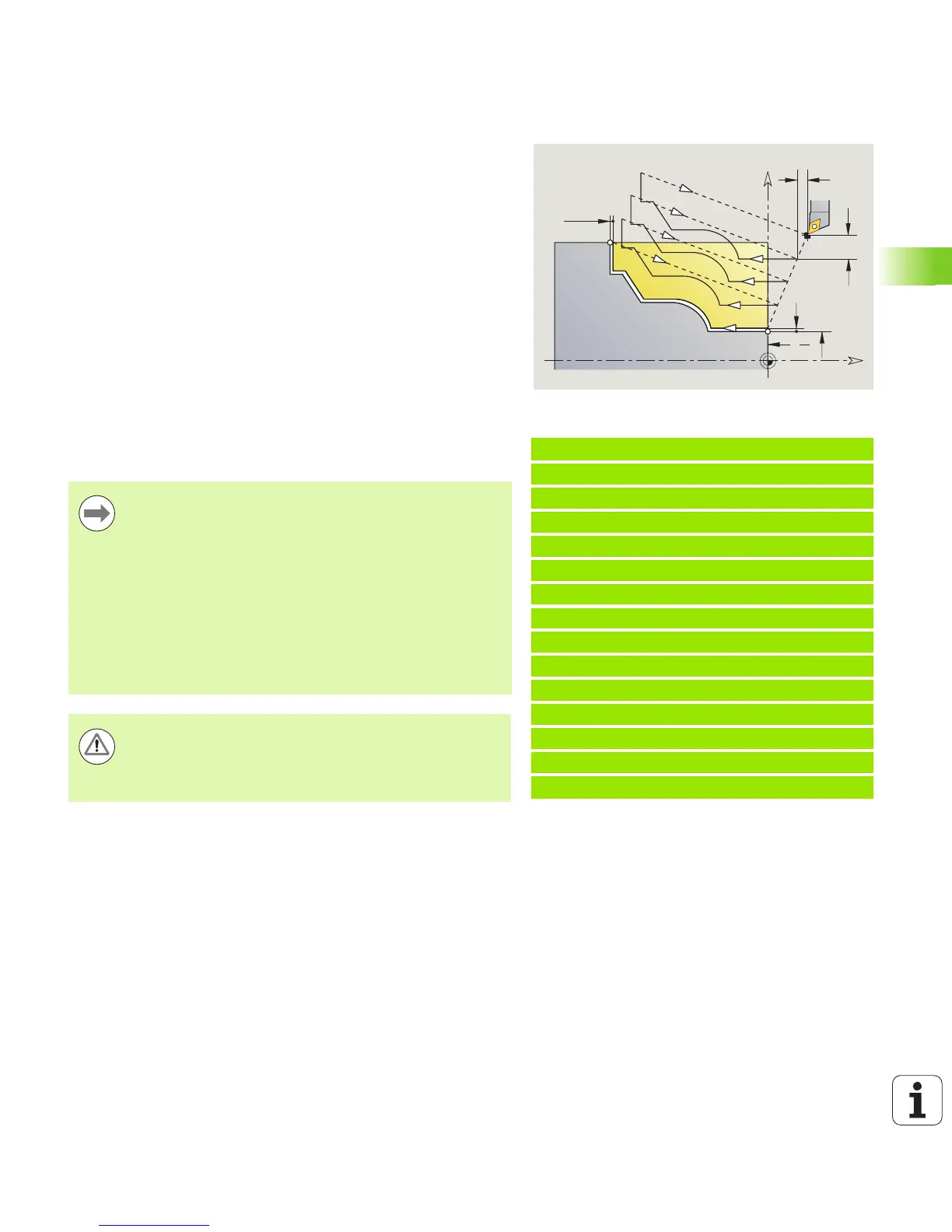

Contour repeat cycle G83

G83 carries out the functions programmed in the following blocks

(simple traverses or cycles without a contour definition) more than

once. G80 ends the machining cycle.

If the number of infeeds differs for the X and Z axes, the tool first

advances in both axes with the programmed values. The infeed is set

to zero if the target value for one direction is reached.

Programming:

G83 is alone in the block

G83 must not be nested, not even by calling subprograms

Example: G83

. . .

N1 T3 G95 F0.25 G96 S200 M3

N2 G0 X120 Z2

N3 G83 X80 Z0 I4 K0.3

N4 G0 X80 Z0

N5 G1 Z-15 B-1

N6 G1 X102 B2

N7 G1 Z-22

N8 G1 X90 Zi-12 B1

N9 G1 Zi-6

N10 G1 X100 A80 B-1

N11 G1 Z-47

N12 G1 X110

N13 G0 Z2

N14 G80

Parameters

X Contour target point (diameter)—(default: Load the last X

coordinate)

Z Contour target point—(default: Load the last Z coordinate)

I Maximum infeed in X direction (radius)—(default: 0)

K Maximum infeed in Z direction (default: 0)

The tool radius compensation is not active. You can

program the TRC separately with G40 to G42.

Safety clearance after each pass: 1 mm

A G57 oversize

Is calculated with algebraic sign (oversizes are

therefore impossible for inside contour machining)

Remains effective after cycle end

A G58 oversize

Is taken into account if you work with TRC

Remains effective after cycle end

Danger of collision!

After each pass, the tool returns on a diagonal path before

it advances for the next pass. If required, program an

additional rapid traverse path to avoid a collision.

Loading...

Loading...