Dust on devices may cause electrostatic discharge and result in poor contact for

connectors or metal connection points. This problem can shorten the life span of

devices and cause faults.

The equipment room must be free from explosive, conductive, magnetically-

permeable, and corrosive dust. Table 4-64 lists the requirement for dust

concentration in the equipment room.

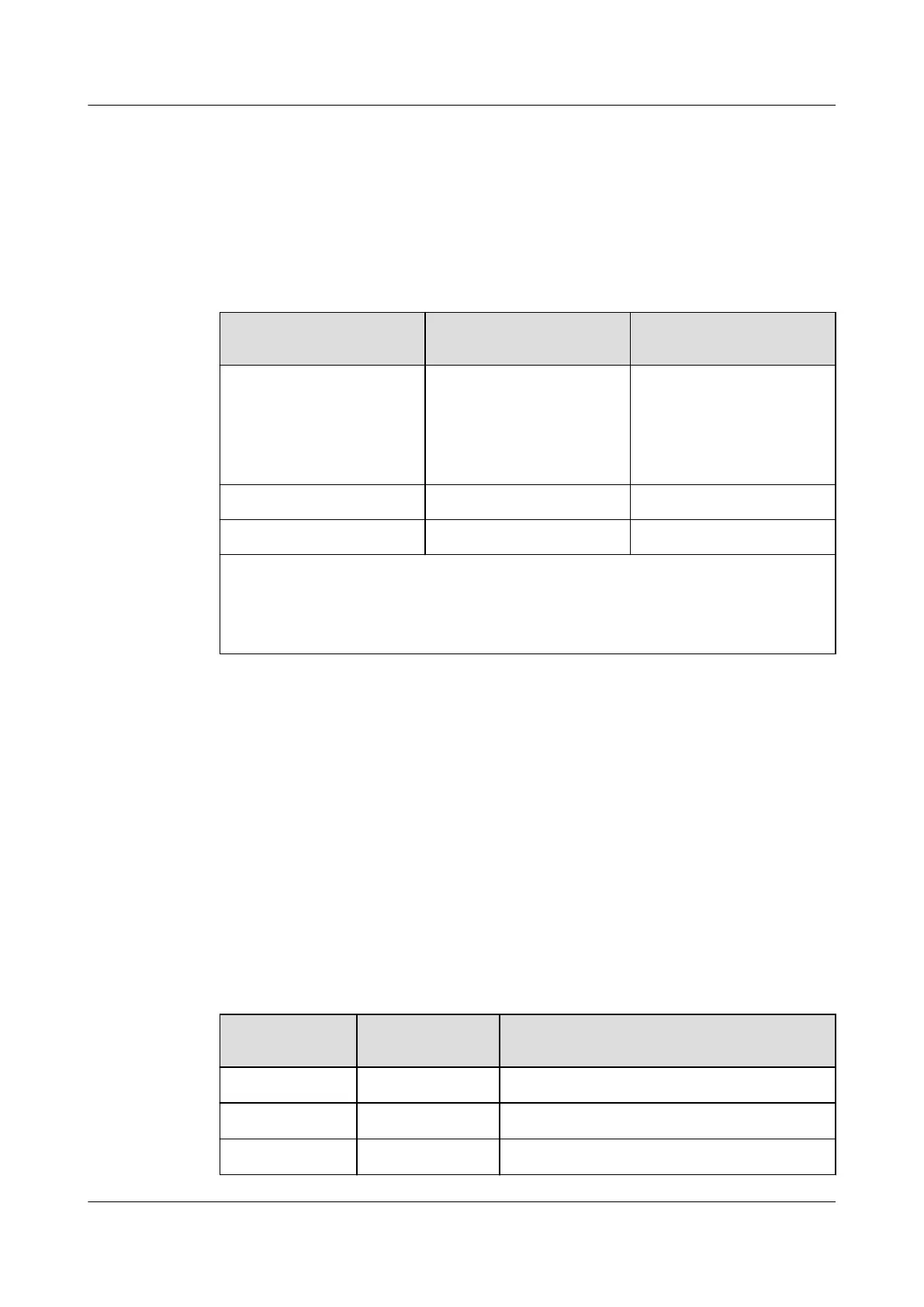

Table 4-64 Requirements for dust particles in the equipment room

Mechanical active

material

Unit Concentration

Dust particle

Particle /m

3

≤ 3x 10

4

(no visible dust

accumulated on a

workbench in three

days)

Suspending dust

mg/m

3

≤0.2

Precipitable dust

mg/m

2

·h

≤1.5

NOTE

● Dust particle diameter ≥ 5 µm

● Suspending dust diameter ≤ 75 µm

● 75 µm ≤ precipitable dust diameter ≤ 150 µm

Take the following measures to meet the requirements:

● Use dustproof materials for ground, wall, and ceiling construction.

● Use screens on the door and windows facing outside. The outer windows

should be dust-proof.

● Clean the equipment room regularly and clean the air

lter door monthly.

● Wear shoe covers and ESD clothing before entering the equipment room.

Requirements for Corrosive Gases

The room should be free from dusts and corrosive gases, such as SO

2

, H

2

S, and

NH

3

. Table 4-65 lists the requirements for the corrosive gas concentration.

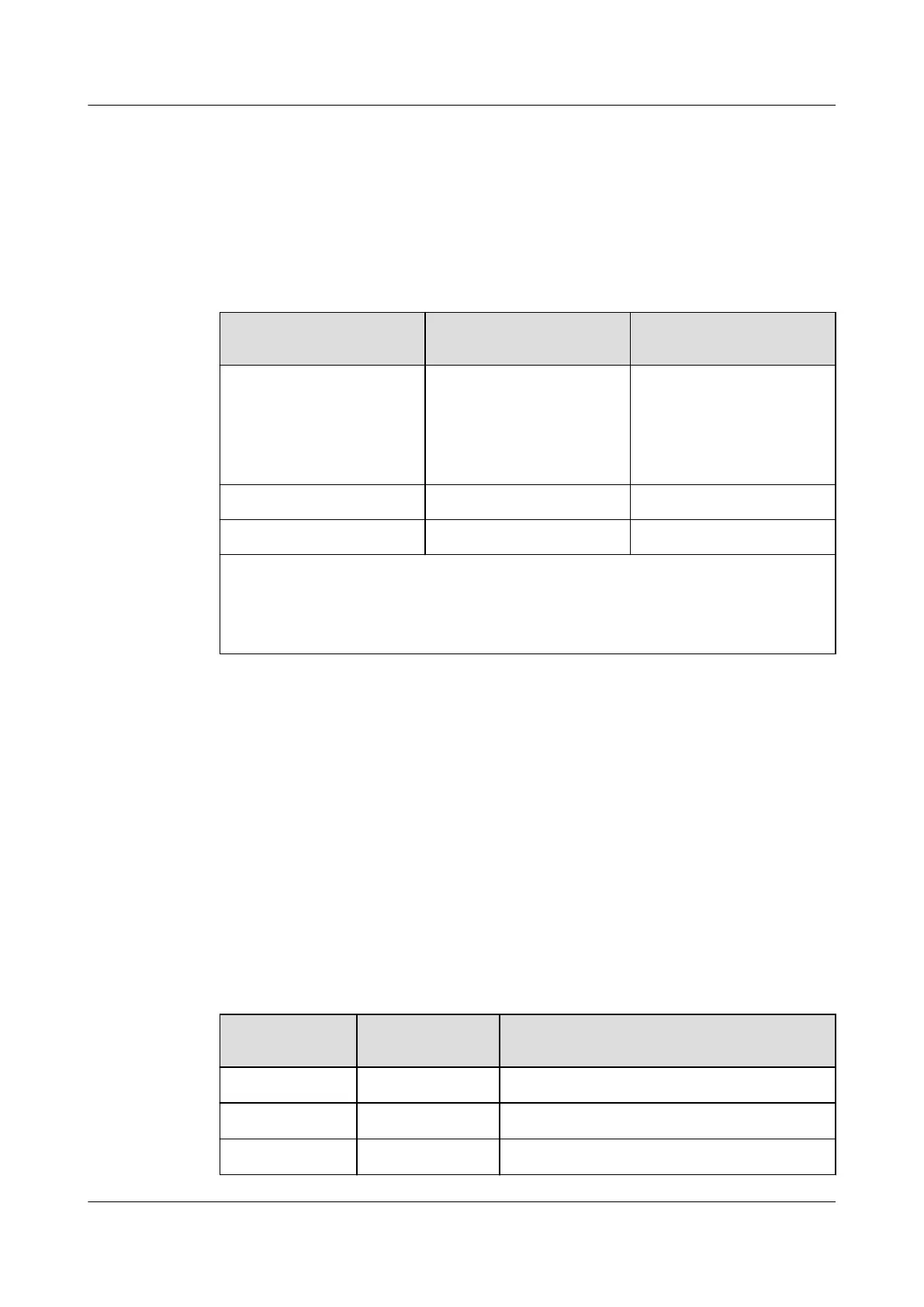

Table 4-65 Requirements for corrosive gas concentration

Chemical

active material

Unit Concentration

SO

2

mg/m

3

≤0.30

H

2

S

mg/m

3

≤0.10

NO

x

mg/m

3

≤0.50

HUAWEI NetEngine 8000 F

Hardware Guide 4 Hardware Installation and Parts Replacement

Issue 05 (2023-03-31) Copyright © Huawei Technologies Co., Ltd. 644

Loading...

Loading...