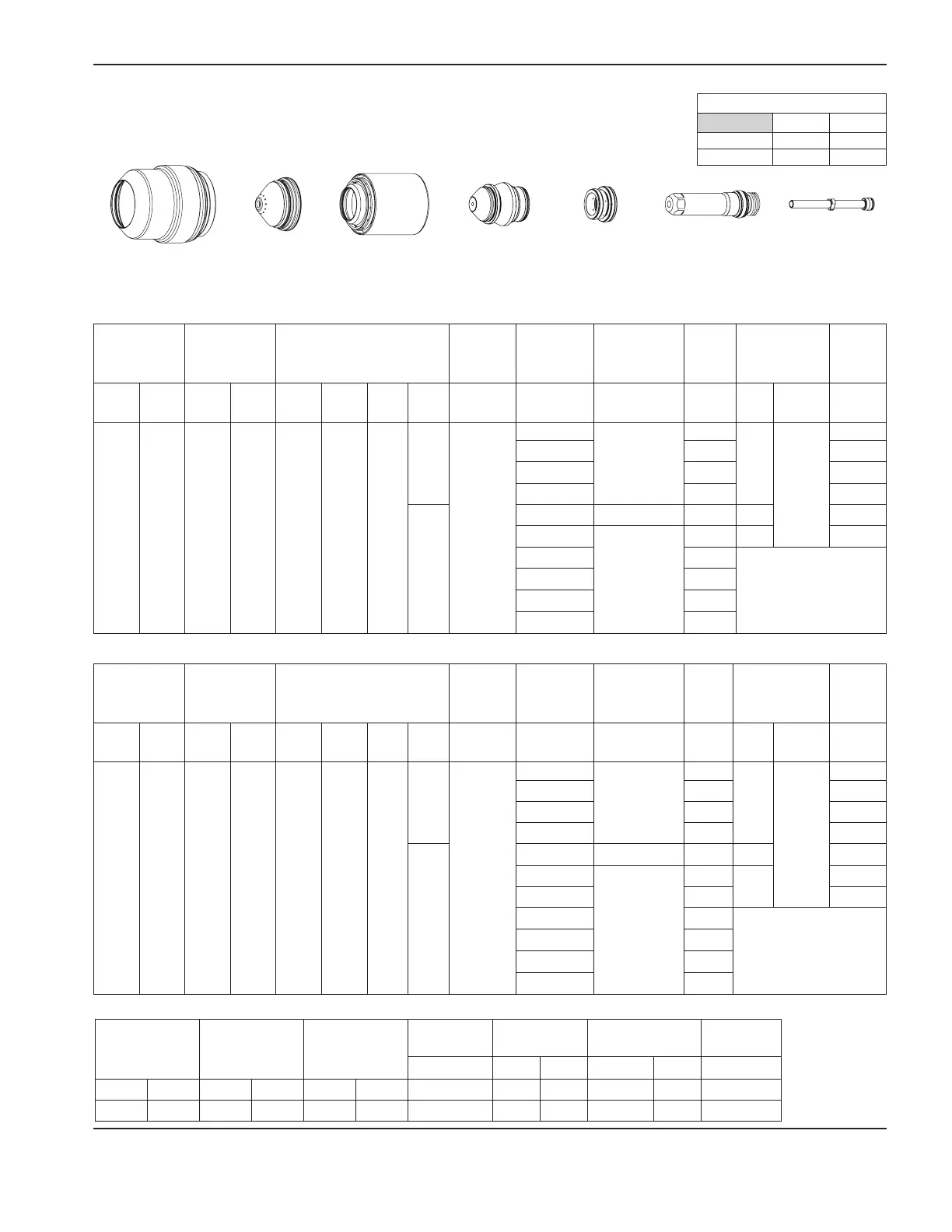

OperatiOn

HPR400XD Auto Gas – 806160 4-83

Metric

English

Select

Gases

Set

Preflow

Set

Cutflow

Minimum

Clearance

Equivalent

Material

Thickness

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce

Height

Pierce

Delay

Time

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

Mix

Gas 1

Mix

Gas 2

mm mm Range (mm) mm/m mm Factor % Seconds

H35 N

2

30 45 88 45 60

40

2.0

12

4.6 – 11.6

2750

14

300

0.4

15 2390 0.5

20 1810 0.7

25 1310 1.0

60

30 5.3 – 11.6 1080 16 2.0

40

6.4 – 11.6

720 19 3.0

50 520

Edge start

60 410

70 310

80 180

Note: Bevel angle range is 0° to 45°.

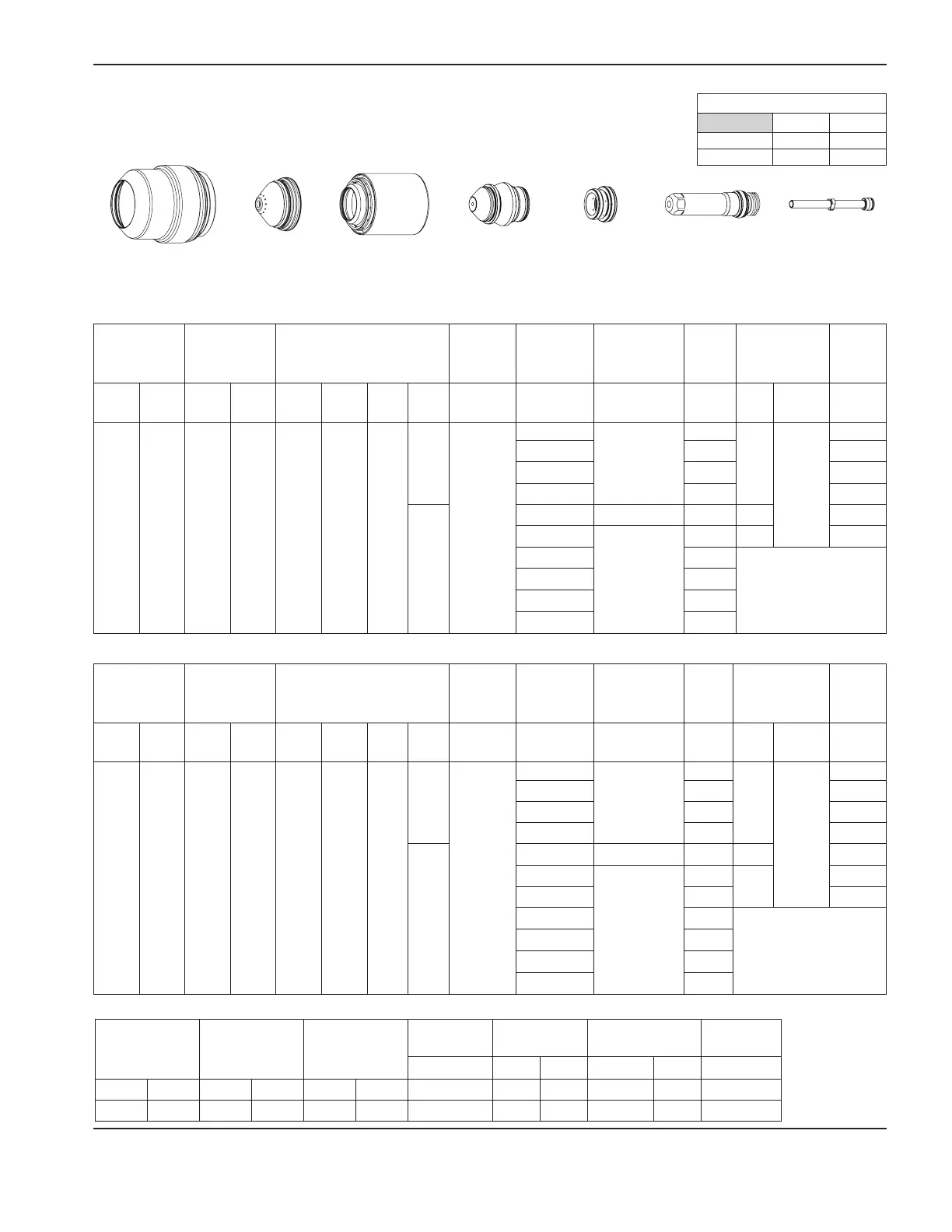

Select

Gases

Set

Preflow

Set

Cutflow

Minimum

Clearance

Equivalent

Material

Thickness

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce

Height

Pierce

Delay

Time

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

Mix

Gas 1

Mix

Gas 2

in in Range (in) ipm in Factor % Seconds

H35 N

2

30 45 88 45 60

40

0.08

1/2

0.18 – 0.46

105

0.5

300

0.4

5/8 90 0.5

3/4 75 0.7

1 50 1.0

60

1-1/4 0.21 – 0.46 40 0.6 1.5

1-1/2

0.25 – 0.46

30

0.8

2.0

1-3/4 25 3.0

2 20

Edge start

2-1/4 17

2-1/2 15

3 10

Marking

Select

Gases

Set

Preflow

Set

Cutflow

Amperage

Torch-to-Work

Distance

Marking

Speed

Arc

Voltage

Amps mm in mm/m ipm Volts

N

2

N

2

10 10 10 10 22 2.5 0.10 1270 50 94

Ar N

2

30 10 30 10 24 3.0 0.12 2540 100 50

Stainless steel bevel cutting

H35 and N

2

Plasma / N

2

Shield

400 A

220707220637 220709220712 220405220708

220571

Flow rates – lpm/scfh

H35 N

2

Preflow 0 / 0 194 / 410

Cutflow 36 / 77 194 / 410

Loading...

Loading...