Power supply wiring recommendations

Protective earth (PE) connection

The protective earth (PE) connection is required for safety and should always be connected to a low

impedance earth point. A Connecting PE to the motor housing solves many noise and EMI problems.

.good grounding of the driver to the earth of the power supply is also essential

PE wire section should be, at least, the same as power supply cables.

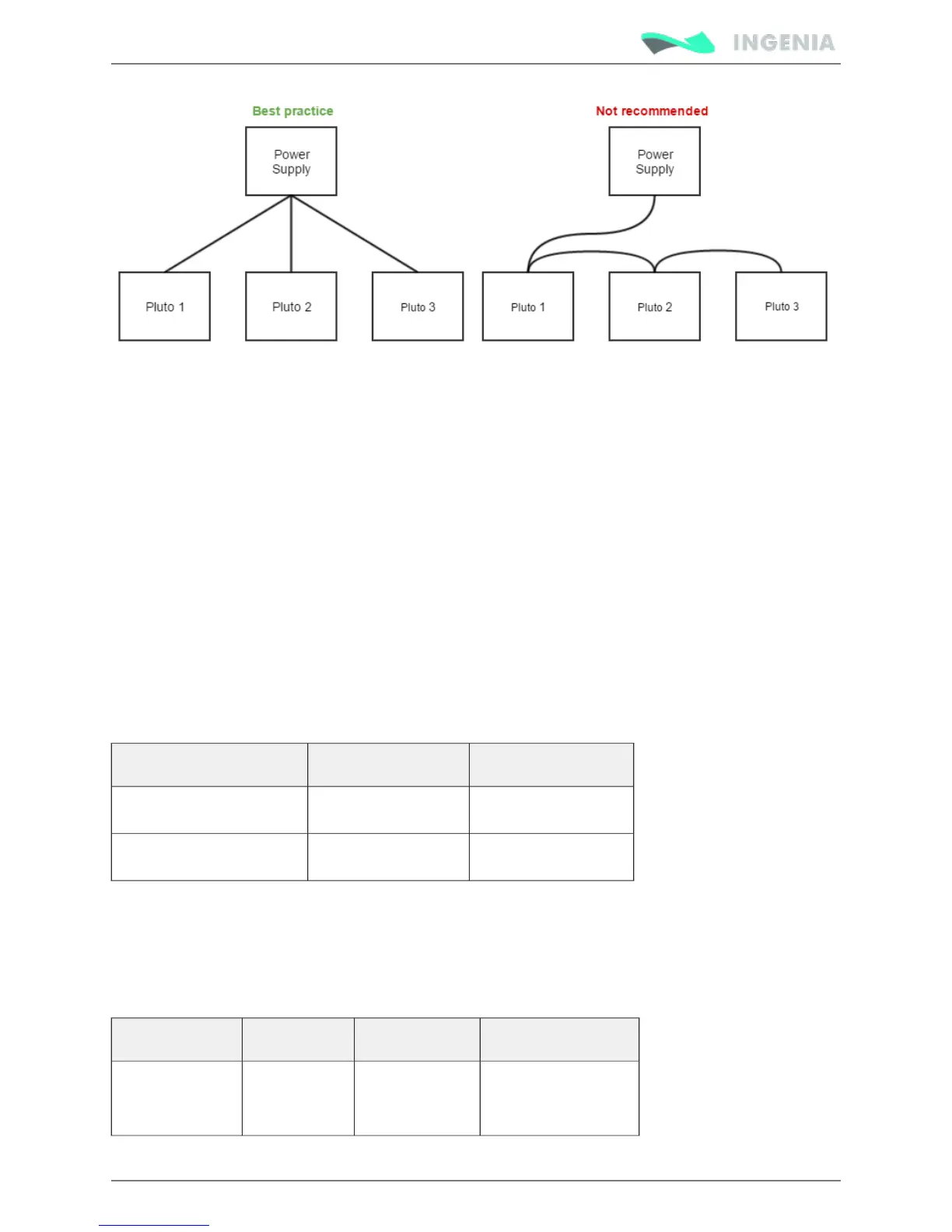

Always minimize PE connection length. Having a central earth connection point is a good practice to avoid

ground loops. Always use good quality plated screws that won’t oxidize or lose conductivity during the

expected lifetime. Whenever possible, mount the Pluto Servo Drive on a metallic conductive surface

connected to earth. Note that the PE terminal is internally connected with the Pluto Servo Drive standoffs.

Wire section

The minimum wire section is determined by the current consumption and the allowed voltage drop across

the conductor. It is preferred to use wide section stranded wires to reduce impedance, power losses and

ease the assembly. Insulator diameter should not exceed 3.5 mm (the connector pitch).

Connection Minimum wire size Maximum wire size

Stranded wire (preferred)

0.5 mm

2

1.5 mm (16 AWG)

2

Solid wire

0.5 mm

2

1.5 mm (16 AWG)

2

Wire ferrules

For low power applications, it is recommended to use wire ferrules to prevent cable damage or wrong

contacts. Due to the connector's size, the maximum allowed ferrule size is 0.5 mm .Ensure crimped

2

ferrule diameter does not exceed 2 mm and the insulator is < 3.5 mm. For higher power applications,

direct cable connection is recommended.

Manufacturer Part number Image Description

Loading...

Loading...