The encoder broken wire detection only works when the encoder is . configured as differential

An will be generated if the encoder is disconnected or some wire is broken.error

To avoid a broken wire fault if the differential encoder has no index (Z) line, connect the negative

pin (ENC_Z-) to GND (this ensures the XOR result = 1) or configure the encoder as single ended in

MotionLab.

Digital Halls interface

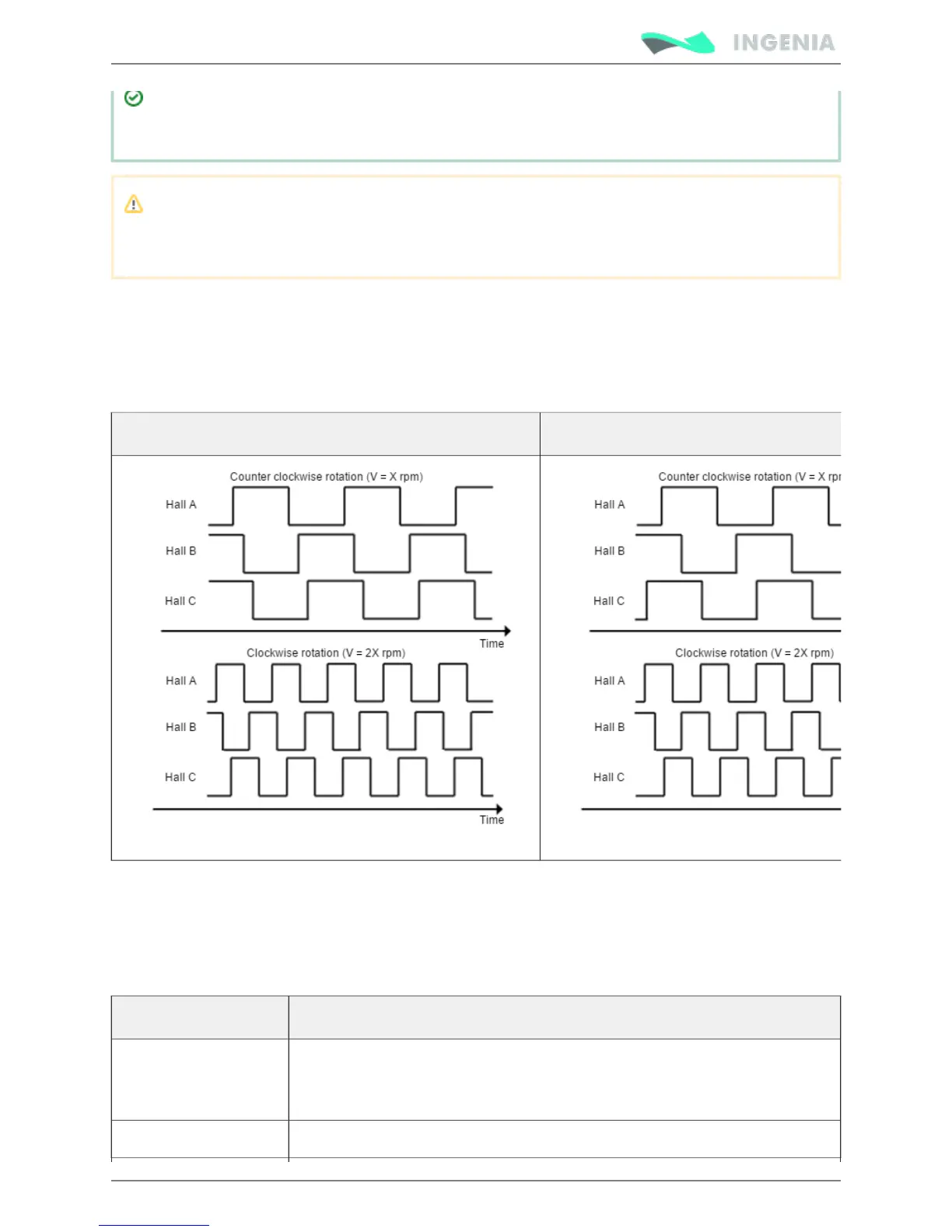

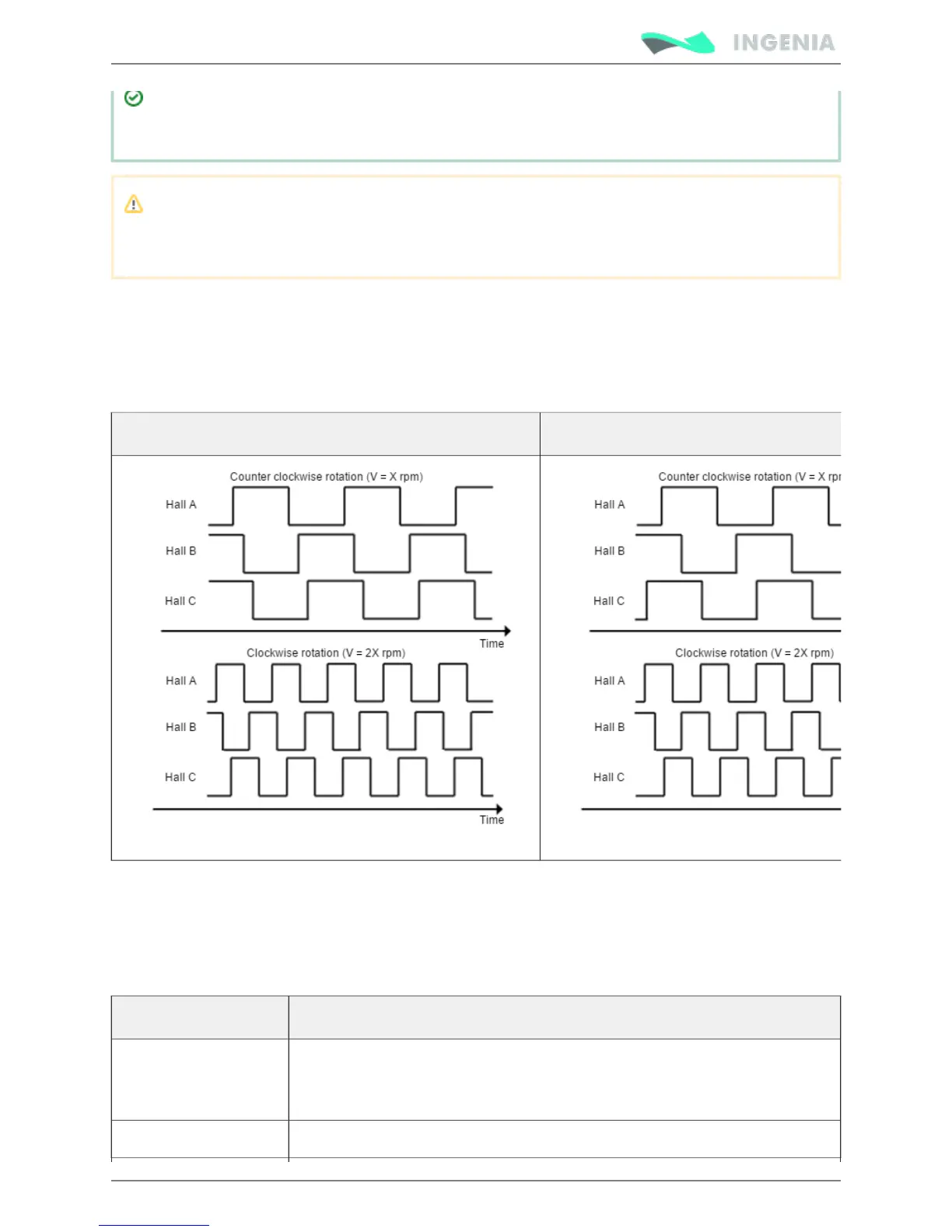

The Hall sensors are Hall effect devices that are built into the motor to detect the position of the rotor

magnetic field. Usually, motors include 3 hall sensors, spaced 60º or 120º apart. Using these 3 signals, the

drive is capable to detect the position, direction and velocity of the rotor. Next figures show examples of

digital halls signals.

Digital halls signals example (60º option) Digital halls signals example (120º option)

Digital halls can be used for commutation, position and velocity control. Resolution using these sensors is

much lower than using encoders. Pluto can use single ended Hall sensors to drive the motor with

trapezoidal commutation, but not with sinusoidal commutation.

This interface accepts 0-5 V level input signals. Inputs are pulled up to 5 V, so industry standard open

collector and logic output hall effect sensors can be connected. Next table summarizes digital halls inputs

main features:

Specification Value

Type of inputs Non-isolated

Single ended with pull-up and low pass filter

ESD protected

Loading...

Loading...