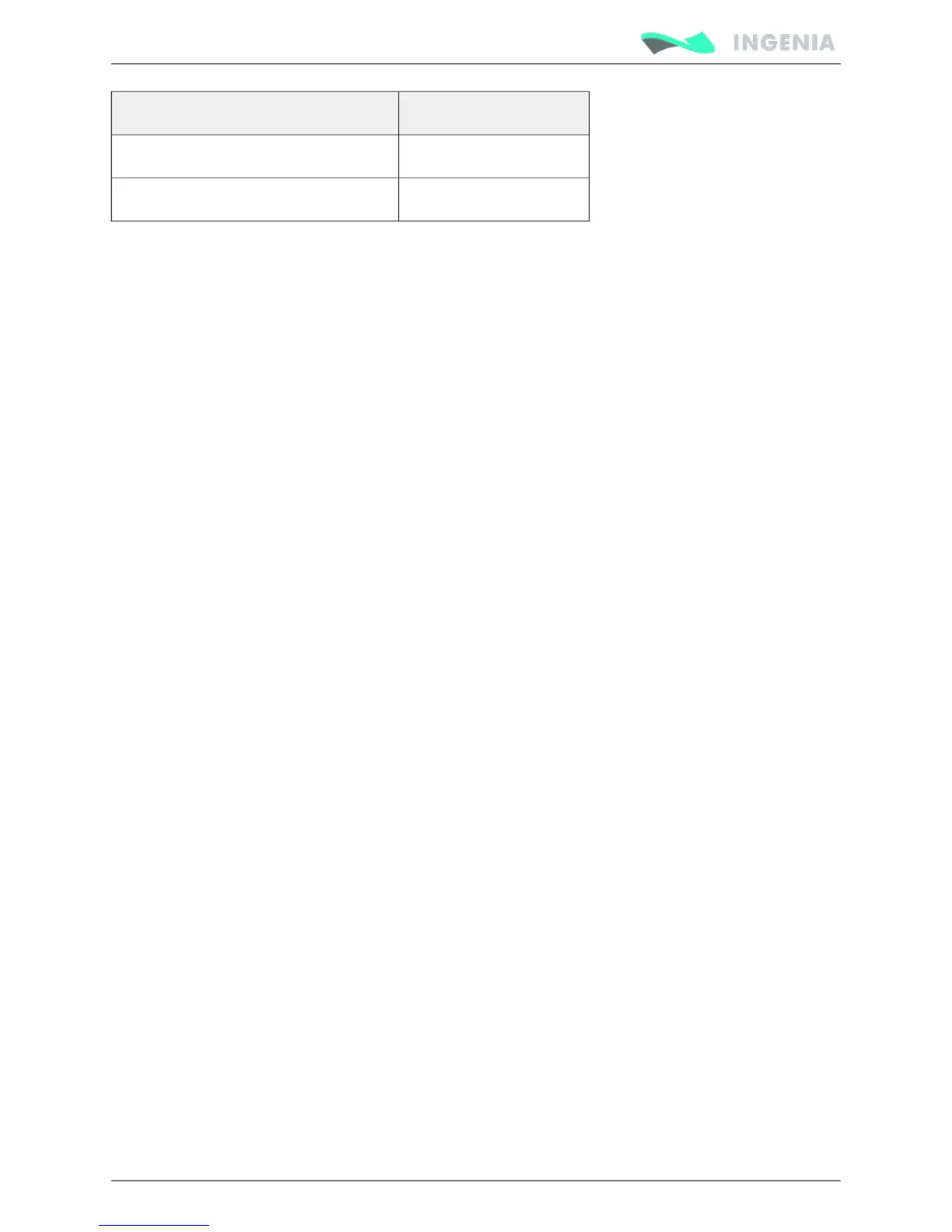

Command source Controlled parameter

Analog input (+/- 10 V o 0 – 5 V) Position, velocity, torque

PWM command Position, velocity, torque

Network interface

Pluto Servo Drive can utilize network communication as a form of input command. Supported network

interfaces for Pluto Servo drive are (CANopen protocol), and .CAN USB RS-485

USB interface is not suitable for long distances or noisy environments. This protocol is only recommended

for configuration purposes. For normal operation, it is suggested to use the CAN interface or the RS-485

interface. These interfaces are more robust against noise than USB, and allows higher distances between

the Pluto Servo Drive and the commander. Using these command sources, target position, velocity or

torque can be set.

Standalone

Pluto Servo Drive is provided with an internal non volatile memory. Through the appropriate software

tool, user can save instructions to this 1 Mb (128K x 8bit) EEPROM, allowing Pluto Servo Drive to work in

standalone mode. In this mode, there is no need of an external command source.

The user can program macros configuring target position, velocity or torque. Interface with general

purpose inputs and outputs can also be programmed in the macros.

This feature can be very useful in applications such as production lines or test equipment, where repetitive

movements are usual. Please refer to for further information.Programming your Drive

Analog input

User can control the target position, velocity or torque using an analog signal. Any of the general purpose

analog inputs can be used as command source (depending on input voltage range and type of output of

the commander).

Pluto Servo Drive provides two analog inputs, one +/-10 V differential input and one 0 to 5 V single ended

input. Refer to for more details about analog inputs.Analog inputs interface

The examples shown below are implemented in the .IO Starter Kit Documentation Home

The next picture shows how to connect a potentiometer to get a 0 to 5 V input single ended.

Loading...

Loading...