1.

2.

3.

Refer to for more information about connections and wires. Refer to Feedback wiring recommendations

for more information about High Speed digital inputs.High-speed (HS) digital inputs interface

PWM encoder wiring should be physically isolated from motor, AC power and all other power

wiring.

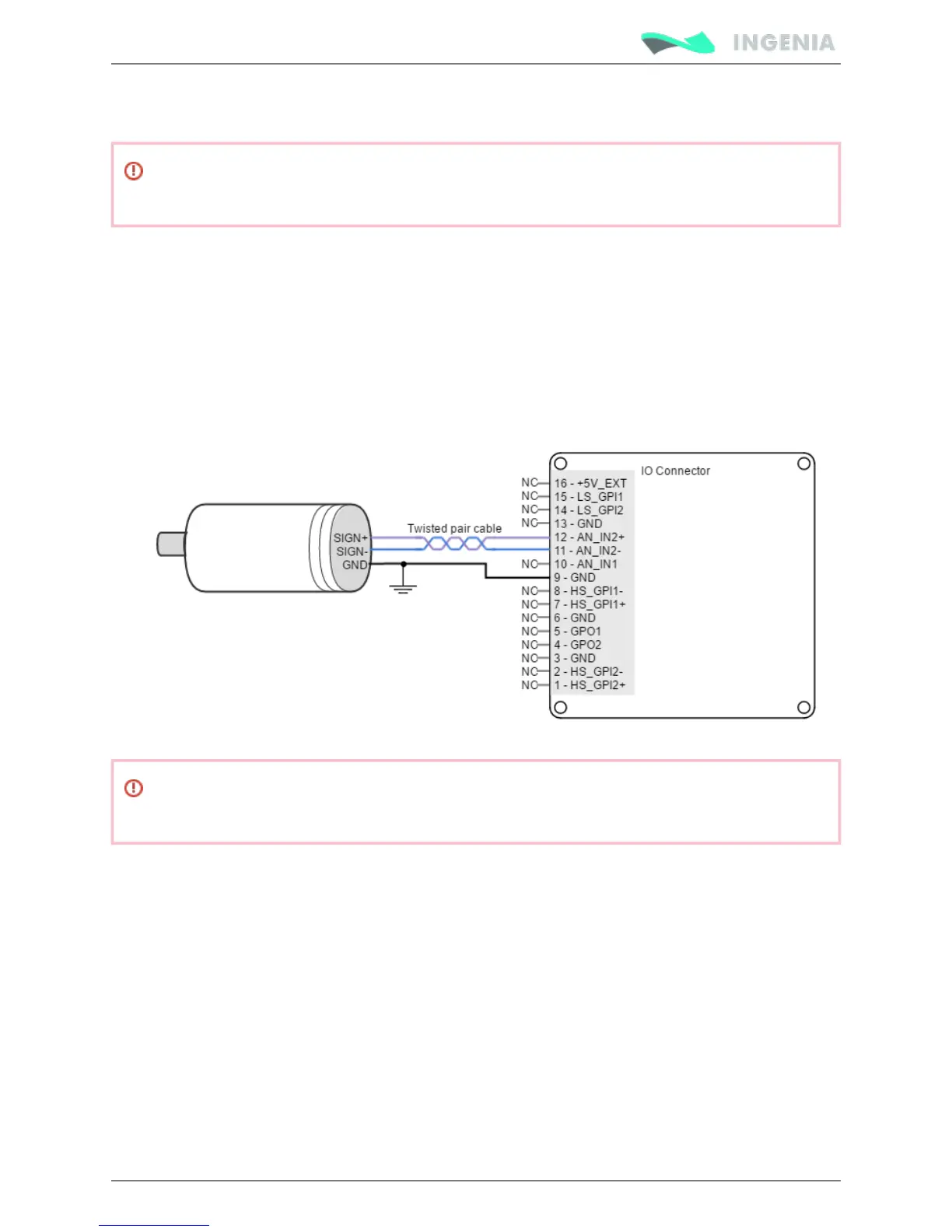

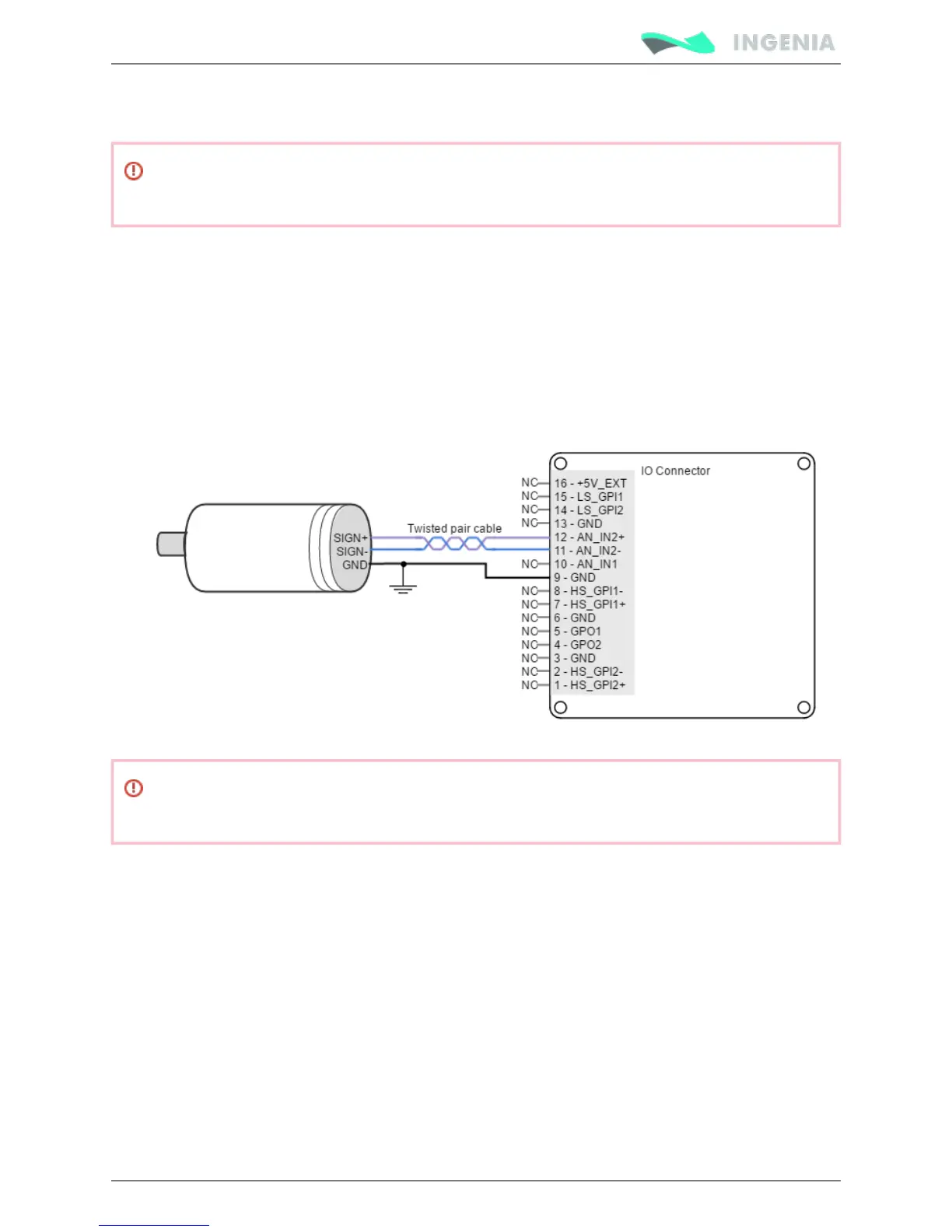

DC tachometer

The Pluto Servo Drive can use a DC tachometer signal as velocity feedback element. Tachometer provides

an analog signal whose voltage level is proportional to the rotor speed.

There are two analog inputs with different input voltage range. Any of them can be used as velocity

feedback input, and can be selected via software depending on the voltage range of the feedback element

and its kind of output (single ended or differential).

Next figure illustrates how to connect source tachometer to the Pluto Servo Drive for differential sources.

DC tachometer feedback wiring should be physically isolated from motor, AC power and all other

power wiring.

Feedback wiring recommendations

The most frequent problems encountered in transmitting feedbacks signals to the receiving electronics

are signal distortion and electrical noise. Either problem can result in gain or loss of counts for digital

feedbacks or bad voltage levels for analog ones. To minimize these problems there are some essential

good wiring practices that should followed:

Always connect both positive and negative signals when using differential digital encoders, Hall

sensors, PWM encoders or analog feedbacks. Use one twisted pair for each differential group of

signals and another twisted pair for the 5 V supply and GND.

Keep the ground connection between an encoder and the Pluto Servo Drive even if the encoder

supply is not provided by the drive. In very noisy environments, connect the cable shield to the

connector shield only at one side. Never use the shield as a conductor carrying a signal, for example

as a ground line.

Loading...

Loading...