Goodrive300-LIFT series inverter Communication protocol

-129-

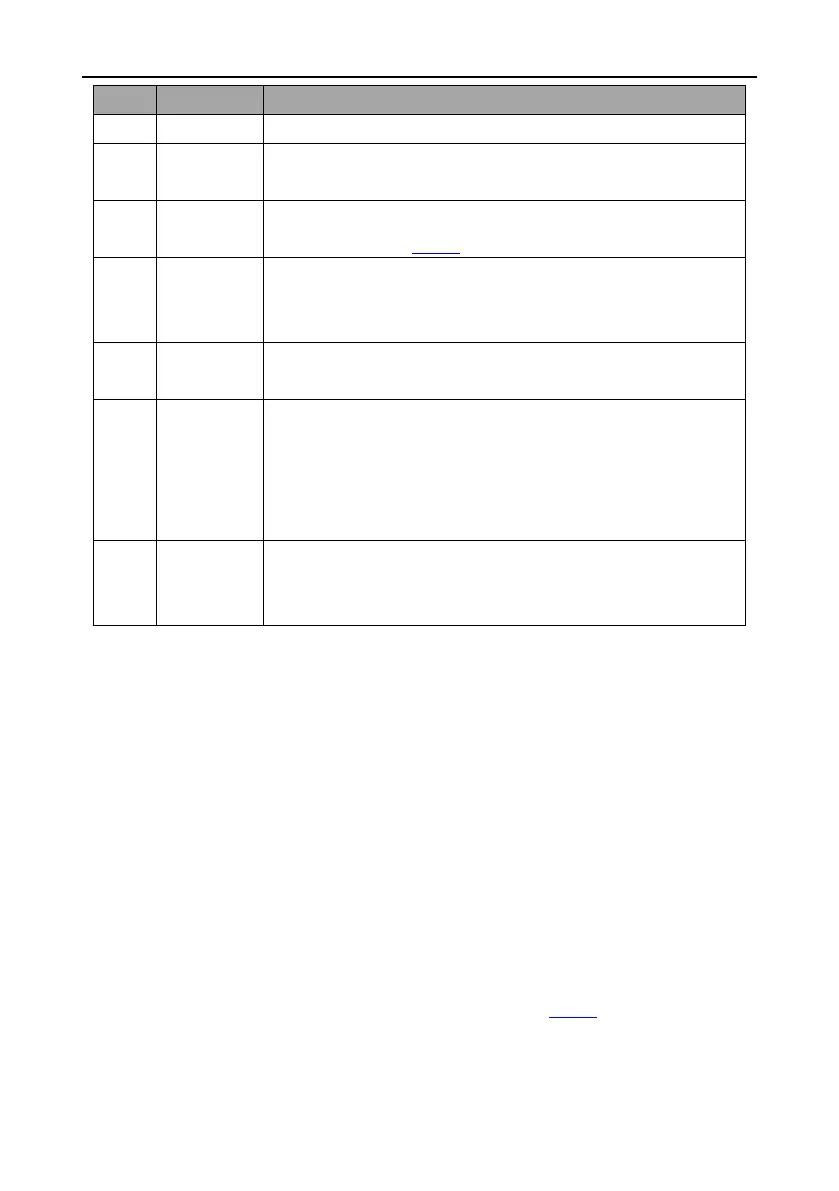

the range, but indicate the message frame is an illegal frame.

The parameter setting in parameter writing is invalid. For example,

the function input terminal cannot be set repeatedly.

The password written to the password check address is not same as

the password set by P07.00.

In the frame message sent by the upper monitor, the length of the

digital frame is incorrect or the counting of CRC check bit in RTU is

different from the lower monitor.

It only happen in write command

Parameters

cannot be

changed

during

running

The modified parameter in the writing of the upper monitor cannot be

modified during running.

When the upper monitor is writing or reading and the user password

is set without password unlocking, it will report that the system is

locked.

The slave uses functional code fields and fault addresses to indicate it is a normal response or some

error occurs (named as objection response). For normal responses, the slave shows corresponding

function codes, digital address or sub-function codes as the response. For objection responses, the

slave returns a code which equals the normal code, but the first byte is logic 1.

For example: when the master sends a message to the slave, requiring it to read a group of address

data of the inverter function codes, there will be following function codes:

0 0 0 0 0 0 1 1 (Hex 03H)

For normal responses, the slave responds the same codes, while for objection responses, it will

return:

1 0 0 0 0 0 1 1 (Hex 83H)

Besides the function codes modification for the objection fault, the slave will respond a byte of

abnormal code which defines the error reason.

When the master receives the response for the objection, in a typical processing, it will send the

message again or modify the corresponding order.

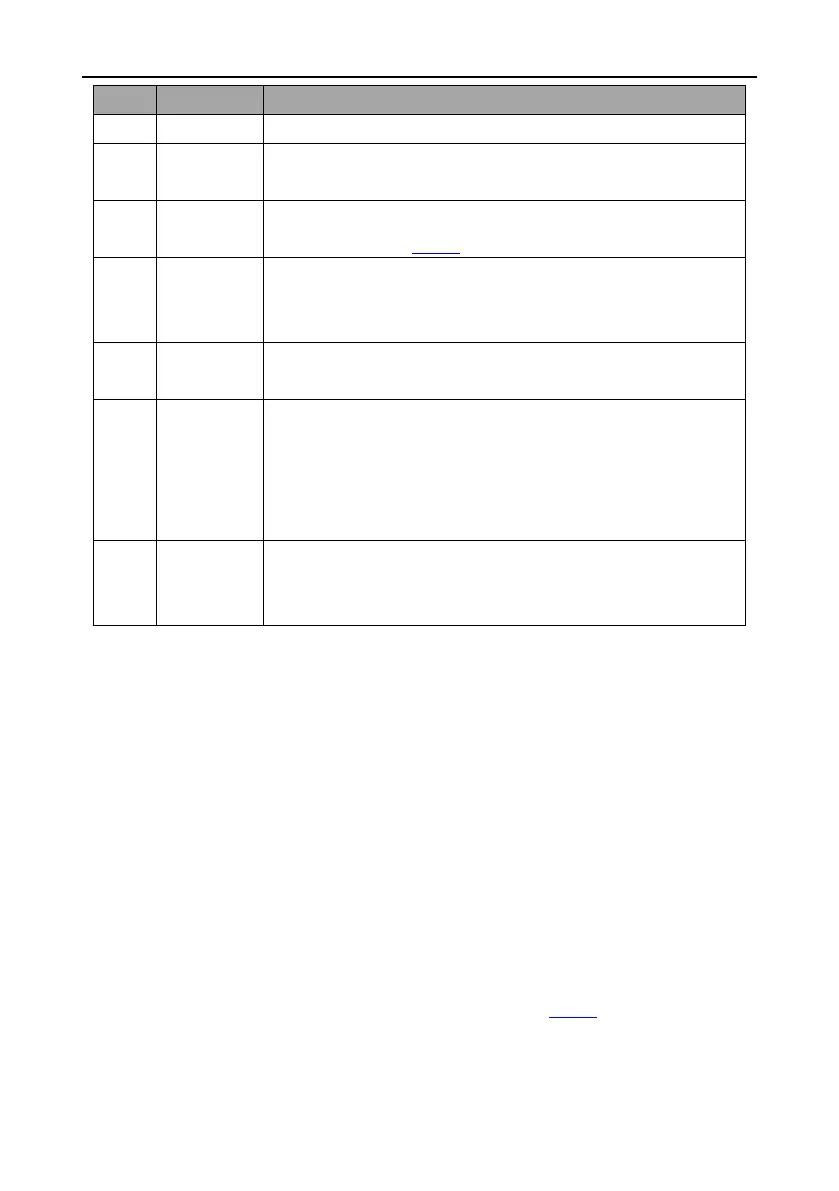

For example, set the "running command channel" of the inverter (P00.01, parameter address is

0001H) with the address of 01H to 03, the command is as following:

Loading...

Loading...