Functionality

USER MANUAL FPC 200 - 3/2017 15

2.1 Protections in general

Within this chapter the general theory of protection functions is described. For clear understanding several time

characteristics for different scenarios are presented.

Default values

Default values are presented as bold.

Example:

Minimum value of pickup delay is 0 ms, maximum

value is 1000 ms. Default value is set to 5 ms.

Table 2 Example of default parameter setting.

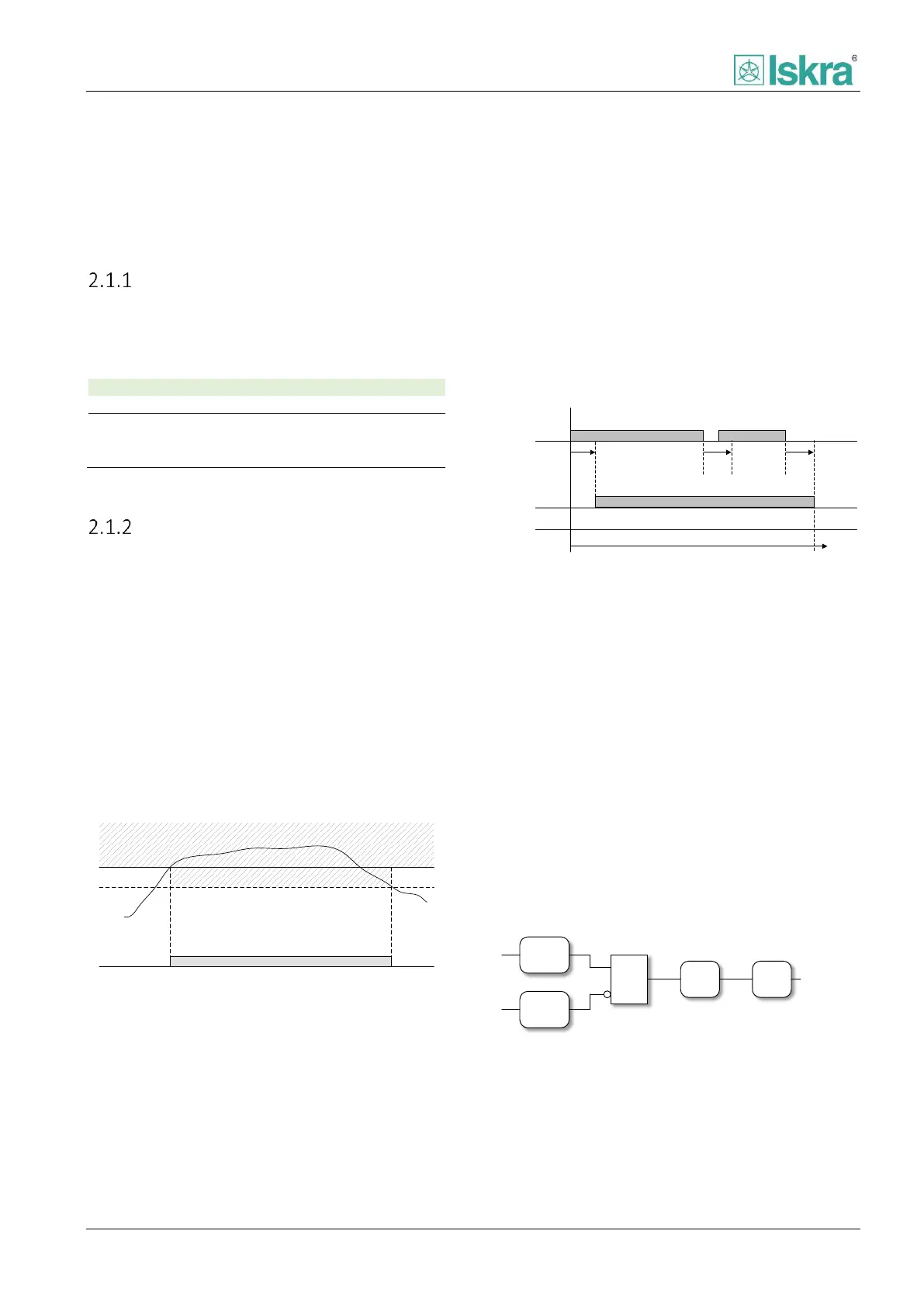

Protection operation range

Fault is detected when monitored value exceeds the

chosen threshold (pickup value). At that point the

protection enters into protection operation range or

fault area. To prevent unwanted switching a hysteresis

characteristic is introduced. Drop-out value is set

relative to pickup value.

When the monitored value enters the protection

operating range the protections picks up. On the other

hand when the value falls below the operating range the

protection drops or resets.

Protection operation range is shown on Figure 2.1.

Pickup value

Drop-out value

Fault detection

Monitored value

Fault area

Figure 2.1: Protection operation range - fault area.

Example: Nominal current of protected element I

n_obj

is

set to 300 A, pickup value is set to 1,1 I

n_obj

and Drop-out

is 0,95 I

p

. The protection will pick up when current

exceeds 330 A. It will drop out when the current drops

below 313,5 A.

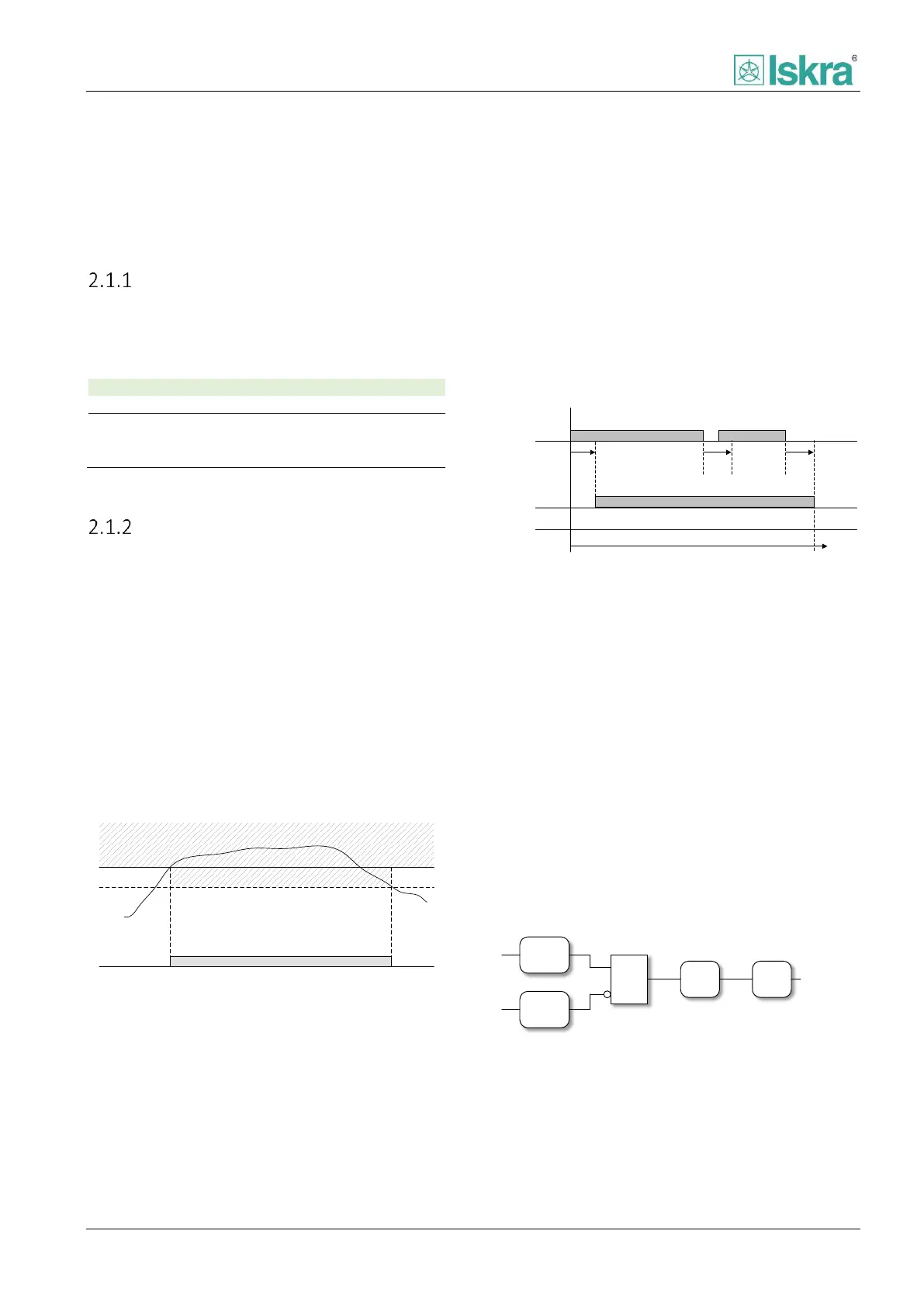

Operational scenario is illustrated on Figure 2.2. Drop-

out delay prevents the timer of protection function to

reset in case the fault falls below the pickup value for a

short period of time. It is usually used when very long

time characteristics are used. In case the protection

trips, drop out delay is not accounted for and other

means of delaying trip signal are used.

Pickup signal

Fault detection

Trip signal

Pickup

delay

Trip delay

Drop-out

delay

Drop-out

delay

Figure 2.2: Pickup signal and Trip signal when fault duration is

shorter than trip delay.

2.1.2.1 Pickup logic

The pickup signal indicates that monitored value

exceeded the set value and indicates that a fault

occurred (Figure 2.2). The pickup delay is intended for

fault signalling stabilization to prevent the short-lived

disturbances in the measuring part of the system from

being reported as faults (Figure 2.4).

The pickup is set (Figure 2.3):

When a fault is detected and

Pickup delay confirmation time runs out and

There is no blocking

Fault

detection

Pickup

Blocking

Pickup

Delay

Pickup

&

Figure 2.3: Pickup set logic.

Loading...

Loading...