Functionality

USER MANUAL FPC 200 - 3/2017 55

Locked rotor protection, excessive starting time - ANSI code 48/51LR/14

Failure of a rotating machine to accelerate when its stator is energized can be caused by several types of abnormal

conditions, including mechanical failure of the machine or load bearings, low supply voltage, or an open circuit in one

phase of a three-phase voltage supply. When a rotating machine stator winding is energized with the rotor stationary, the

machine performs like a transformer with resistance-loaded secondary winding. Stator winding currents may typically

range from three to seven or more times the rated full-load value, depending on the machine design and supply system

impedance.

Although the rotating machine starting current does drop off near full speed, this effect is normally neglected, providing

some safety margin from relay operation during rotor acceleration.

2.5.4.1 Functionality

Considering the current amplitude on start-up is at

maximum most of the time, the algorithm takes into

account that the start-up current is constant and is

equal to maximum start-up current. Therefore the

allowed start-up time is constant. This function

distinguishes between different rotating machine

conditions, regarding current and digital input states.

Trip of the function is considered as soon as any stated

condition is detected. When rotating machine reaches

stopped state, all signals are set to zero and all timers

are reset.

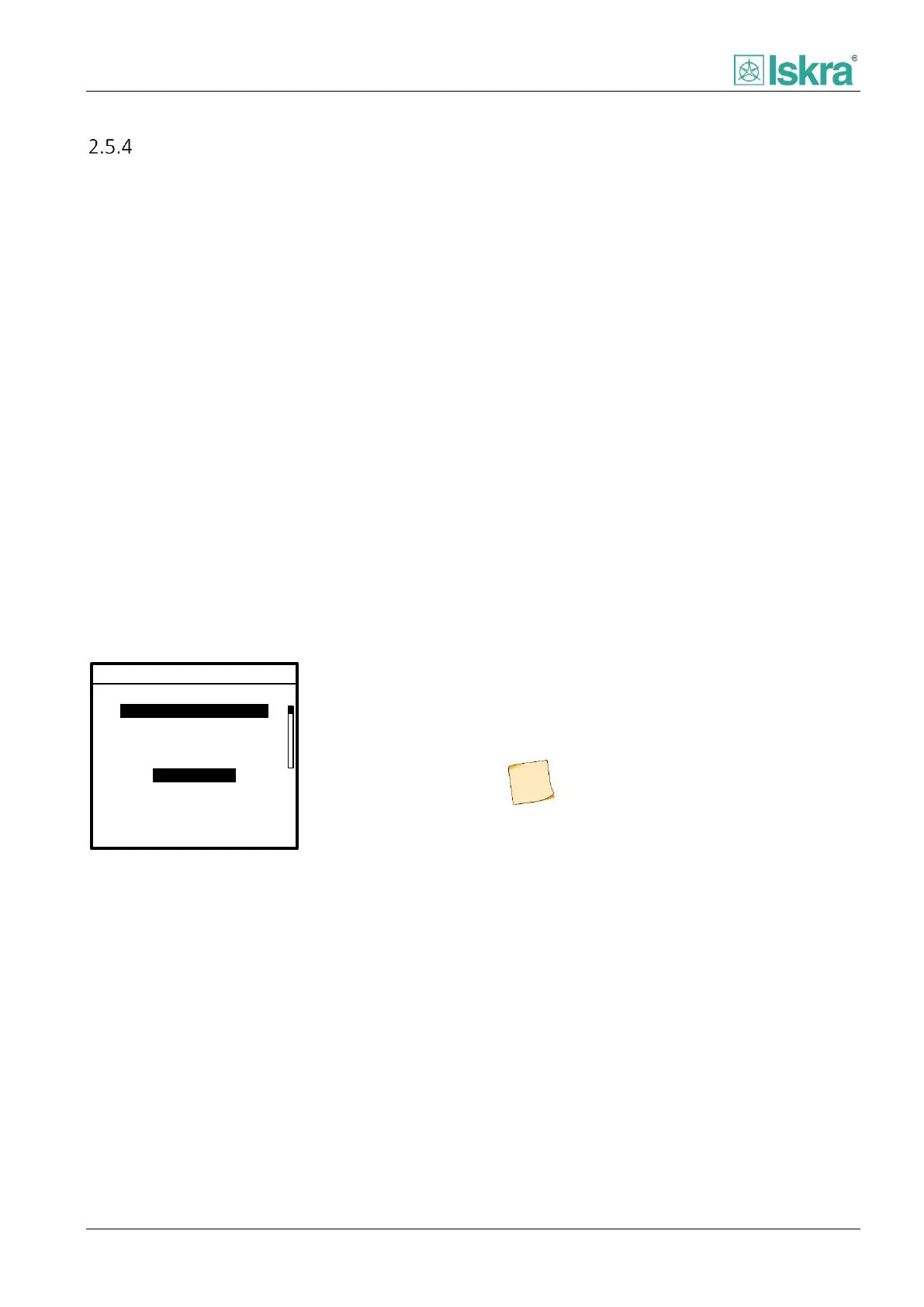

48/51LR/14

Enabled:

:

No

CONTROL SETTINGS

Start-up time:

300,0s

300,0s

Locked start t:

300,8s

Stall time:

COUNTERS

Trip counter:

Excesive start:

Locked start:

0

0

0

Stall:

0

Figure 2.34 Locked rotor function parameters as seen on HMI.

Table 42 Locked rotor, excessive start time on HMI.

2.5.4.1.1 Excessive start – ANSI 48

Condition is considered if starting [2.6.4.3.2] signal is set

for longer period than Start-up time of the machine,

while rotation [2.5.4.3] signal is present.

2.5.4.1.2 Locked start – ANSI 51LR

Condition is considered if starting signal is set for longer

period than Locked start time of the machine, while

there is no rotation signal present.

2.5.4.1.3 Stall – ANSI 14

Condition is considered if stalling [2.6.4.3.6] signal is set

for longer period than Stall time of the machine.

Rotation signal is usually connected to an

external digital input, which is connected

to a rotating machine rotation detector.

Loading...

Loading...