Electrical installation

Page 91

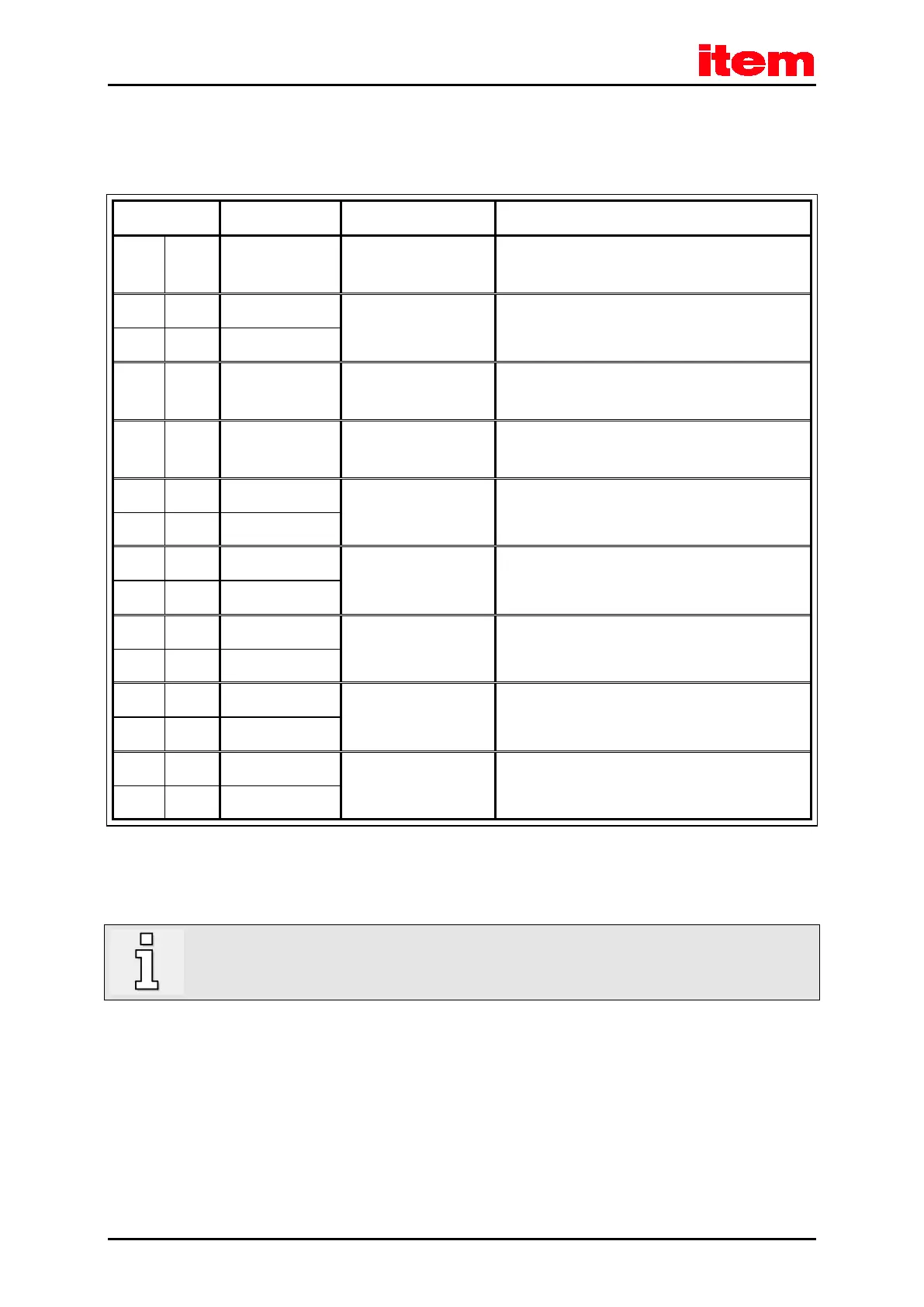

8.7.3 Pin assignment [X2B]

Table 38: Pin assignment: analogue incremental encoder – option [X2B]

1 MT+ + 3.3 V / Ri = 2 kΩ Motor temperature sensor

1)

, normally closed contact,

PTC, KTY ...

9 U_SENS+ 5 V ... 12 V

R

I

≈ 1 kΩ

Sensor cables for the encoder supply

2 U_SENS-

10 US 5 V / 12 V / ± 10%

I

max

= 300 mA

Operating voltage for high-resolution incremental

encoders

3 GND 0 V Reference potential for the encoder supply and motor

temperature sensor

11 R 0.2 V

pp

… 0.8 V

pp

RI ≈ 120 Ω

Index pulse track signal (differential) of the high-

resolution incremental encoder

4 #R

12 COS_Z1

2)

1 V

pp

/ ± 10%

RI ≈ 120 Ω

COSINE commutation signal (differential) of the high-

resolution incremental encoder

5 #COS_Z1

2)

13 SIN_Z1

2)

1 V

pp

/ ± 10%

RI ≈ 120 Ω

SINE commutation signal (differential) of the high-

resolution incremental encoder

6 #SIN_Z1

2)

14 COS_Z0

2)

1 V

pp

/ ± 10%

RI ≈ 120 Ω

COSINE track signal (differential) of the high-

incremental encoder

7 #COS_Z0

2)

15 SIN_Z0

2)

1 V

pp

/ ± 10%

RI ≈ 120 Ω

SINE track signal (differential) of the high-resolution

incremental encoder

8 #SIN_Z0

2)

1)

Please refer to

chapter 9 Additional requirements to be fulfilled by the servo positioning controllers for UL approval

,

page 113.

2)

Heidenhain encoder: A=SIN_Z0; B=COS_Z0; C=SIN_Z1; D=COS_Z1

In addition, the outer cable shield of the angle encoder cable must be connected to the mounting plate of the

controller over a large contact area with the aid of shield terminal SK14.

Loading...

Loading...