Engineering manual - UniSAB III 1.10.8

110/346

001930 en 2021.06

Compressor control and surveillance

Alarm surveillance

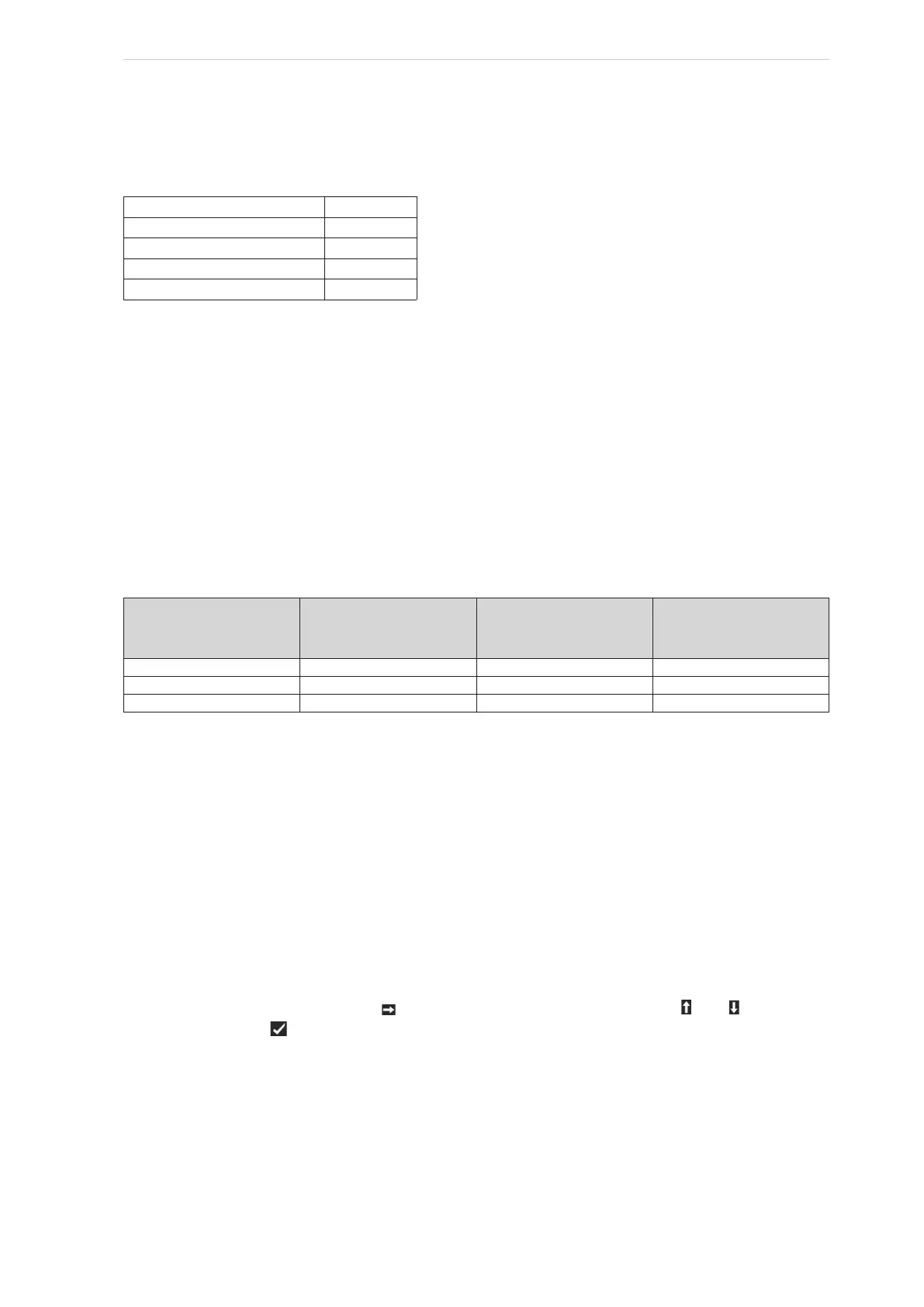

During start the following alarms are delayed:

Low oil pressure 45 sec.

High filter diff. pressure 300 sec.

Low superheat 300 sec.

High superheat 300 sec.

Low/high oil temperature

300 sec.

The delayed alarms are described in section 6.5 Timers.

Stopping sequence

When GST compressor stops, UniSAB III will attempt to move the capacity slide below 5% position. The

solenoid valve for decreasing capacity slide position is activated for maximum 300 seconds. If the ca-

pacity slide is not below 5% within the 300 seconds a Capacity error shutdown will be issued.

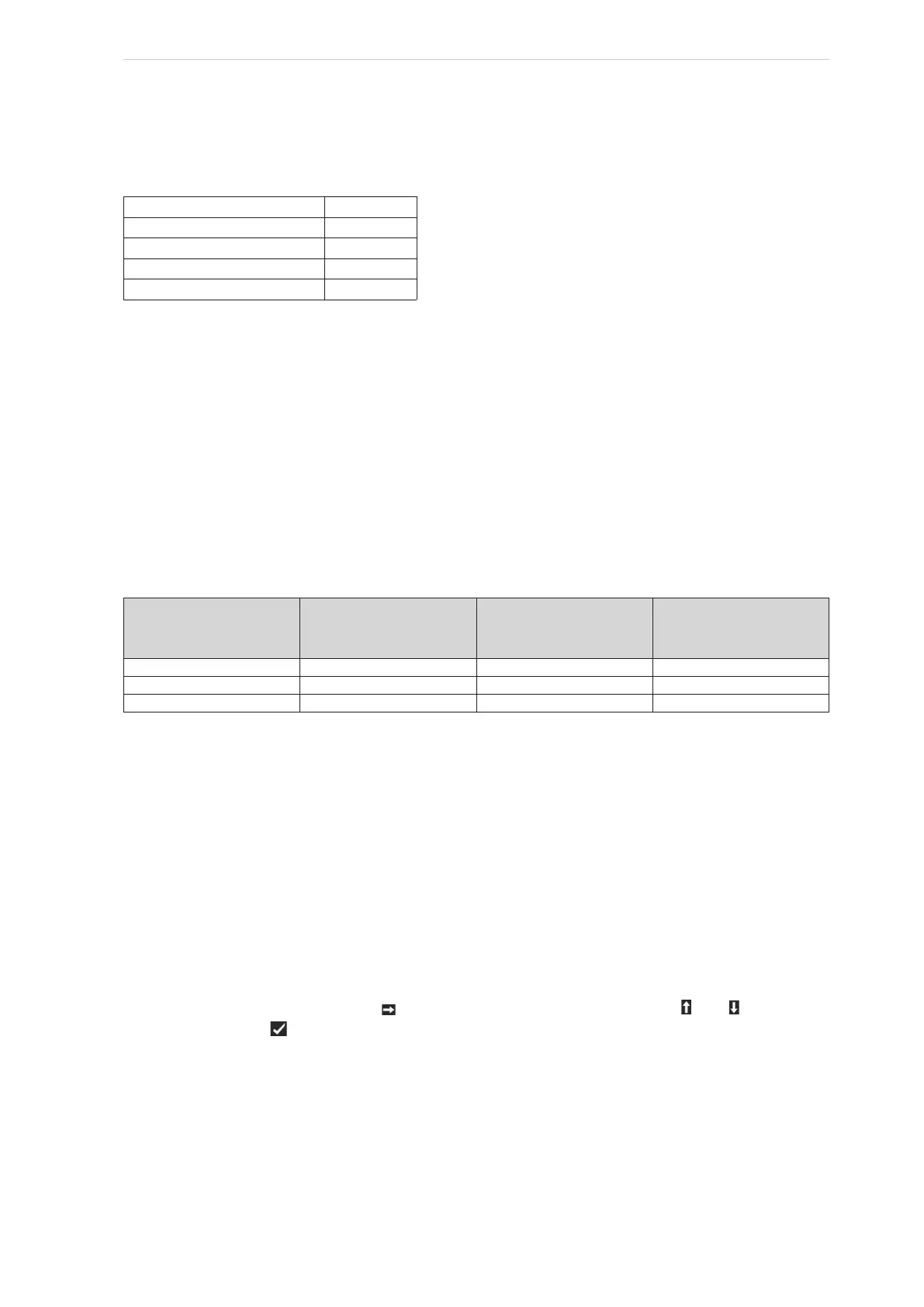

Vi ratio regulation

UniSAB III regulates the Vi ratio in three steps according to the actual pressure ratio. Before switching

from one Vi-step to another, the actual Vi ratio for the compressor must have been present for at least

the time indicated in timer 34 Vi-pause (60 seconds). Otherwise the change of the Vi step will be

cancelled.

Vi slide position

../Capacity/Vi slide

pos.

Dig. output 11 (V1) Dig. output 12 (V2)

Volume ratio 2.2

0.0 % On On

Volume ratio 3.5

65.3 % Off On

Volume ratio 5.0

100.0 % Off Off

3.3.15 SAB 283 Mk 1, SAB 330 and SAB 355 Mk 1 with oil pump

The pump is used for prelubrication and to maintain a minimum oil pressure level during operation. The

pump is started and stopped in accordance with the compressor differential pressure (discharge pres-

sure - suction pressure) during operation.

The difference is set in the picture Oil/Pressure/Control whereupon Set point 1 and Set point 2 will

appear.

Set point 1 is the pump start pressure and Set point 2 is the pump stop pressure. Therefore, Set point 1

must be set to the lowest pressure level.

Normal setting for SAB 283 Mk 1/330/355 Mk 1:

Set point 1 = 2.5 bar

Set point 2 = 4.0 bar

Move the cursor to Set point 1, press to enter the parameter change field, use and to adjust the

value and then press to store the value.

Adjust Set point 2 the same way.

If the compressor differential pressure is below Set point 1 during operation, the pump will start

immediately.

When the compressor differential pressure has been higher than Set point 2 for 60 sec, the pump will

stop.

Loading...

Loading...