75

WATER-COOLED DEVICES

5 Installation and Operation of Liquid-Cooled Devices

5.1 Water-cooled devices

Theuseofwater-cooledKEBCOMBIVERTdrivecontrollersisoered,becausethere

are process-caused coolants available with some applications. However, the following

instructions must be observed.

5.1.1 Heat sink and operating pressure

Design system Material max. operating pres-

sure

Connection

Aluminium heat sink with

stainless steel tubes

Stainless steel 1.4404 10 bar

=> „5.1.4 Connection

of the cooling system“

NOTICE

Deformation of the heat sink!

► In order to avoid a deformation of the heat sink and the damages

thereby, the indicated maximum operating pressure may not be

exceededbrieyalsobypressurepeaks.

► The pressure equipment directive 2014/68/EU on pressure equip-

ment must be observed!

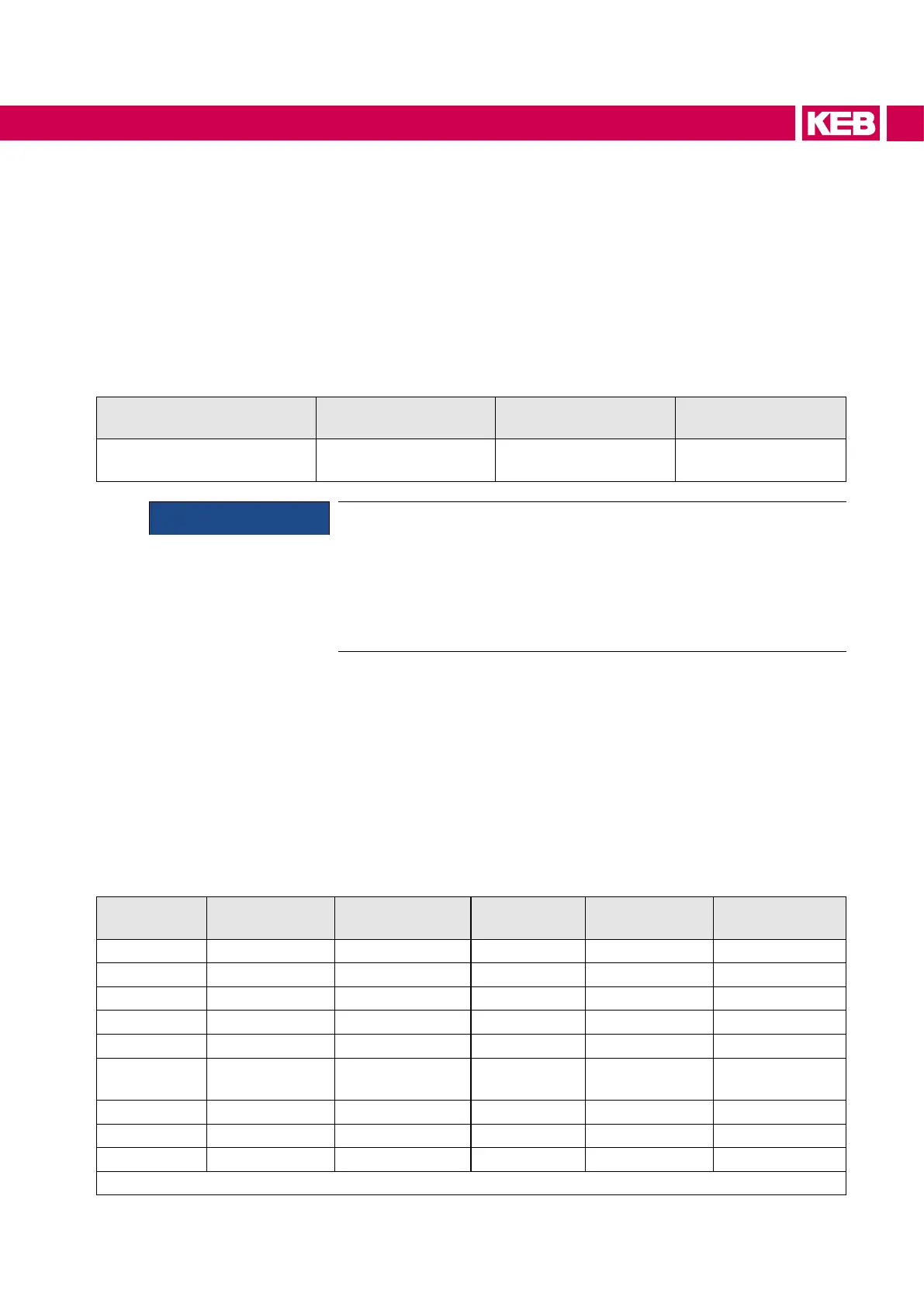

5.1.2 Materials in the cooling circuit

For the screw connections and also for the metallic articles in the cooling circuit which are in con-

tactwiththecoolant(electrolyte)amaterialistobeselected,whichformsasmallvoltagedier-

ence to the heat sink in order to avoid contact corrosion and/or pitting corrosion (electro-chemical

voltageseries,seethefollowingtable).Thespeciccaseofapplicationmustbecheckedbythe

customerintuningofthecompletecoolingcircuitandmustbeclassiedaccordingtotheused

materials. With hoses and seals take care that halogen-free materials are used.

A liability for occuring damages by wrongly used materials and from this resulting corro-

sion cannot be taken over!

Material formed ion Standard poten-

tial

Material formed ion Standard poten-

tial

Lithium Li+ -3.04 V Nickel Ni2+ -0.25 V

Potassium K+ -2.93 V Tin Sn2+ -0.14 V

Calcium Ca2+ -2.87 V Lead Pb3+ -0.13 V

Sodium Na+ -2.71 V Iron Fe3+ -0.037 V

Magnesium Mg2+ -2.38 V Hydrogen 2H+ 0.00 V

Titan Ti2+ -1.75 V Stainless

steel

various 0.2...0.4 V

Aluminium Al3+ -1.67 V Copper Cu2+ 0.34 V

Manganese Mn2+ -1.05 V Carbon C2+ 0.74 V

Zinc Zn2+ -0.76 V Silver Ag+ 0.80 V

continued on the next page

Loading...

Loading...