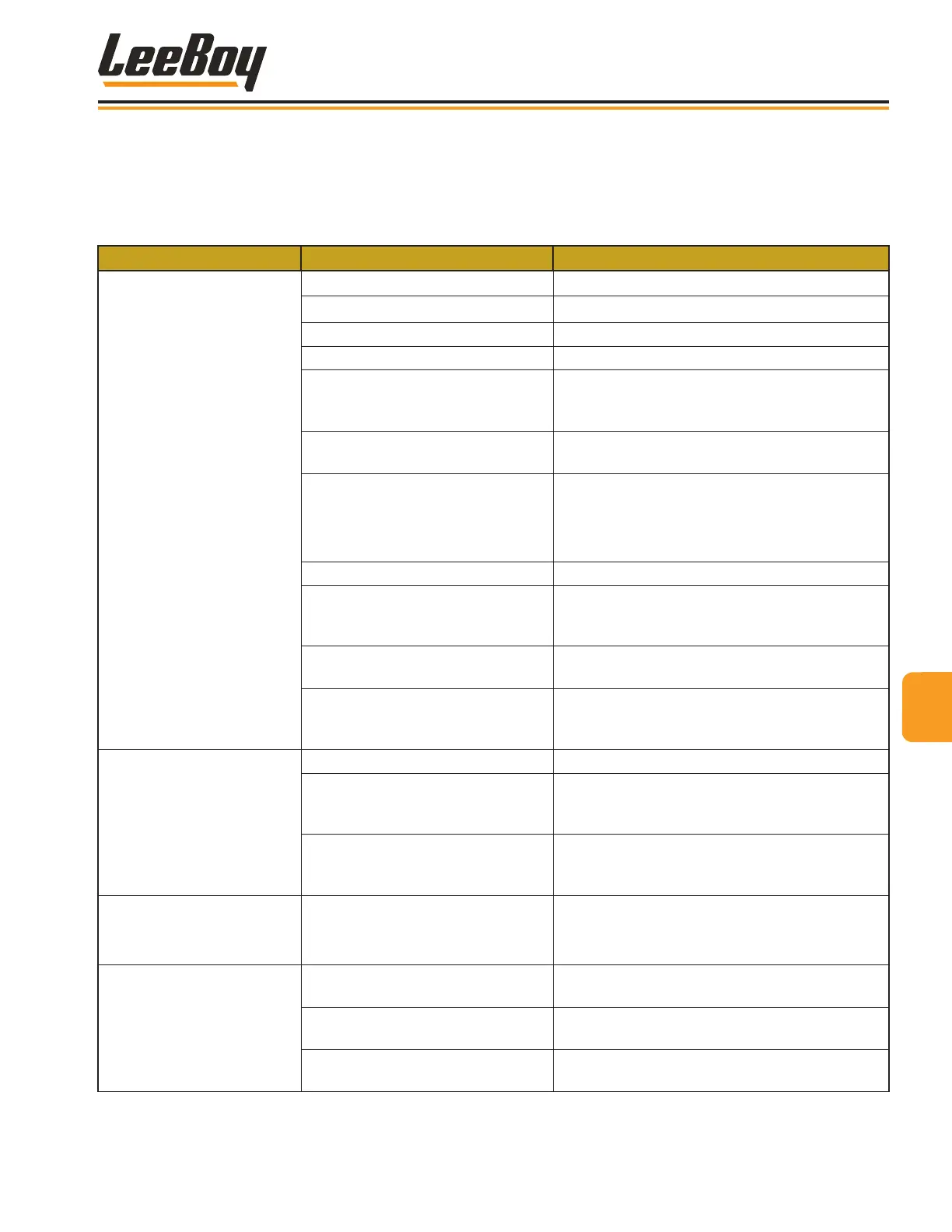

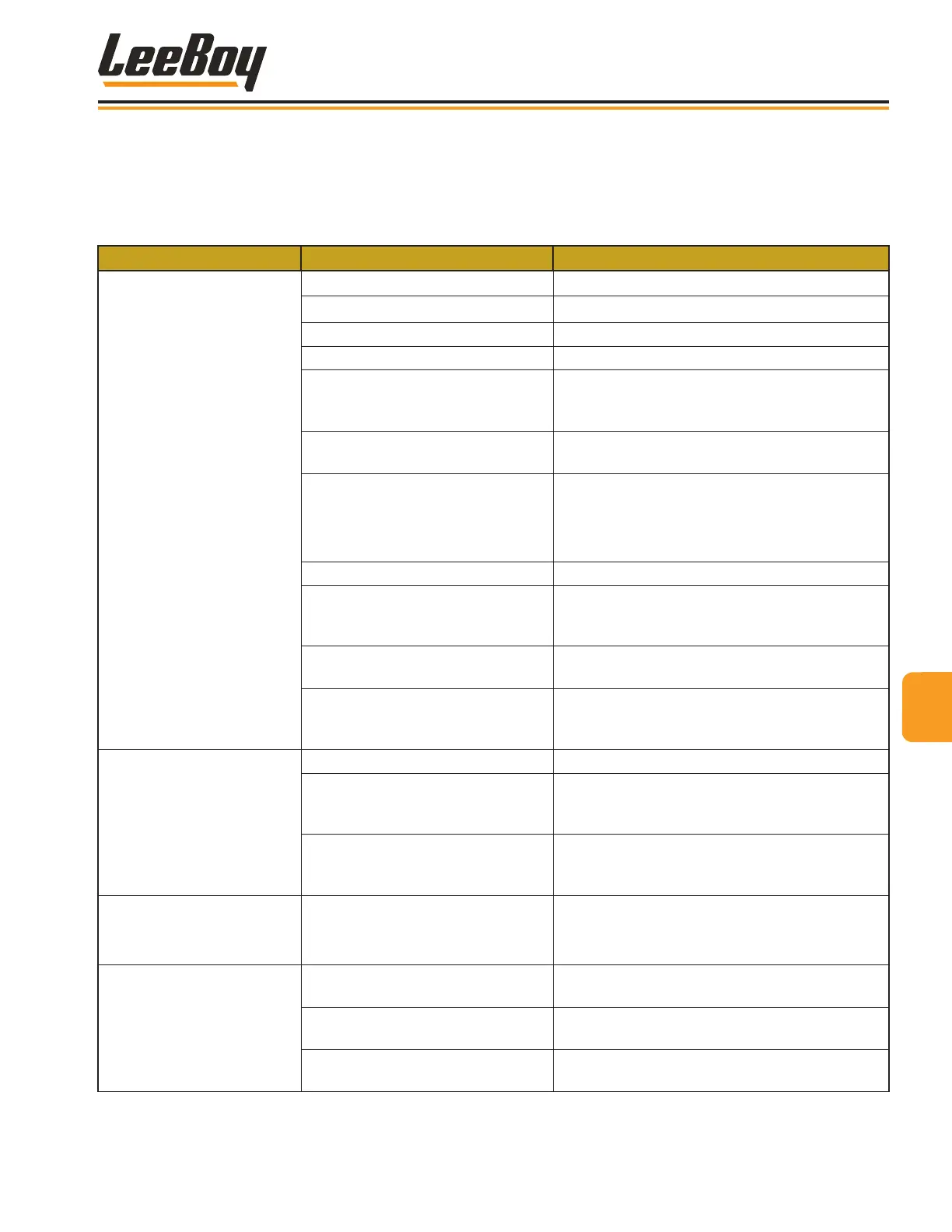

Troubleshooting ChartTroubleshooting Chart

The troubleshooting chart below identies the most common causes of any malfunction and possible remedies. If the

problem persists, see your authorized dealer.

Table 5-4. L300 and L600 Tack Distributor Troubleshooting

SYMPTOM CAUSE REMEDY

Engine does not start.

Engine switch OFF. Turn ON the engine switch.

Choke open (gas enigne only). Move choke lever to CLOSED position.

Insufcient fuel supply. Fill fuel tank.

Fuel valve turned off. Turn on fuel valve.

Bad fuel (or unit placed in long-

term storage without draining

gasoline).

Drain the fuel tank and carburetor, then refuel

with the correct fuel.

Spark plug faulty or improperly

gapped.

Adjust gap or replace spark plug.

Spark plug wet with fuel (ooded

engine),

Unit stored wtihout treating or

draining gasoline.

Dry and reinstall spark plug. Start engine with

throttle lever in the MAX position.

Engine oil level low. Rell oil to the proper level.

Defective battery or low battery

charge (if equipped with electric

starter engine option).

Recharge or replace battery.

Fuse burned out (if equipped with

electric starter engine option).

Replace fuse.

Fuel lter restricted, carburetor

malfunction, valves stuck, ignition

malfunction, etc.

See your authorized dealer for service.

Engine lacks power.

Air lter element(s) restricted. Clean or replace lter element (s).

Engine stored without treating or

draining gasoline, or refueled with

bad gasoline.

Drain fuel tank and carbuerator. Rell gas tank.

Carburetor malfunction, ignition

malfunction, valves stuck or other

malfunction.

See your authorized dealer for service.

Electric starter does not

work (if equipped).

Starter fuse burned out.

Replace fuse.

NOTE: Running the engine will not charge

the battery.

Spray bar malfunctions (if

equipped with this option).

Dried asphalt material blocking

passageway.

Apply heat to the spray bar with hot steam, air or

electrical heat tapes to loosen material.

Faulty or loose wires or

connectors.

Tight, repair or replace electrical wires/

connections.

Asphalt feed hose(s) partially

plugged or collapsed.

Clean or replace hose.

55

Maintenance

L300 and L600 Tack Distributors 5-17

Loading...

Loading...