Page 18

©2013 Technical Marine Service, Inc. LC-100 V2.97

The too large bubbler presents a different set of

concerns. The LevelCom 100 admits measured

charges of air into the sense line system and

each charge of air will displace the fluid in the

bubbler pipe by a certain amount. If the bubbler

pipe diameter is too large, it is possible that the

measured charges of air will not displace the

fluid in the bubbler pipe far enough to detect a

good reading. In this case the LevelCom 100

will not be able to detect when bubbles are

being blown from the end of the tank, and this

can result in significant reading errors.

Maximum diameter for a bubbler pipe should

not exceed 1.5 inches.

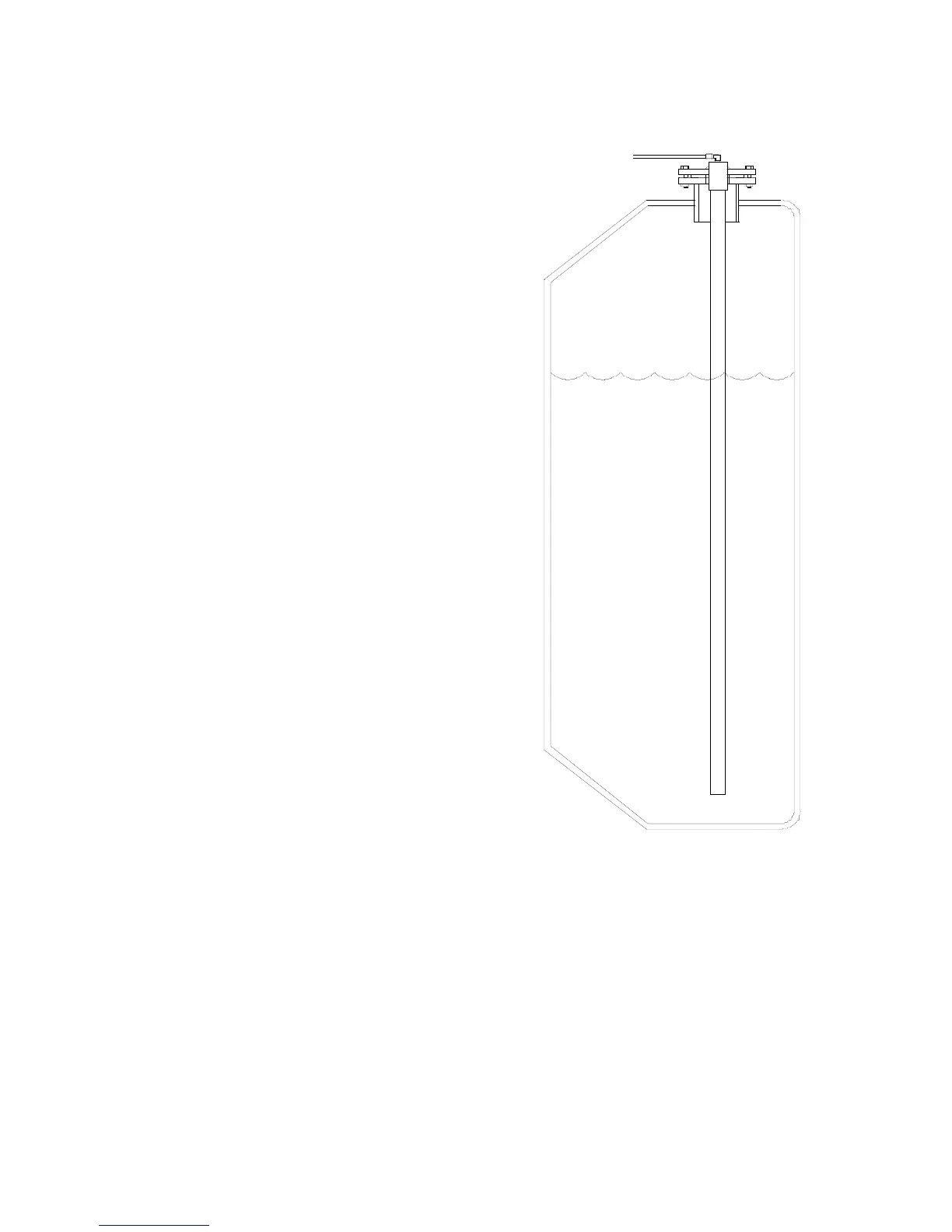

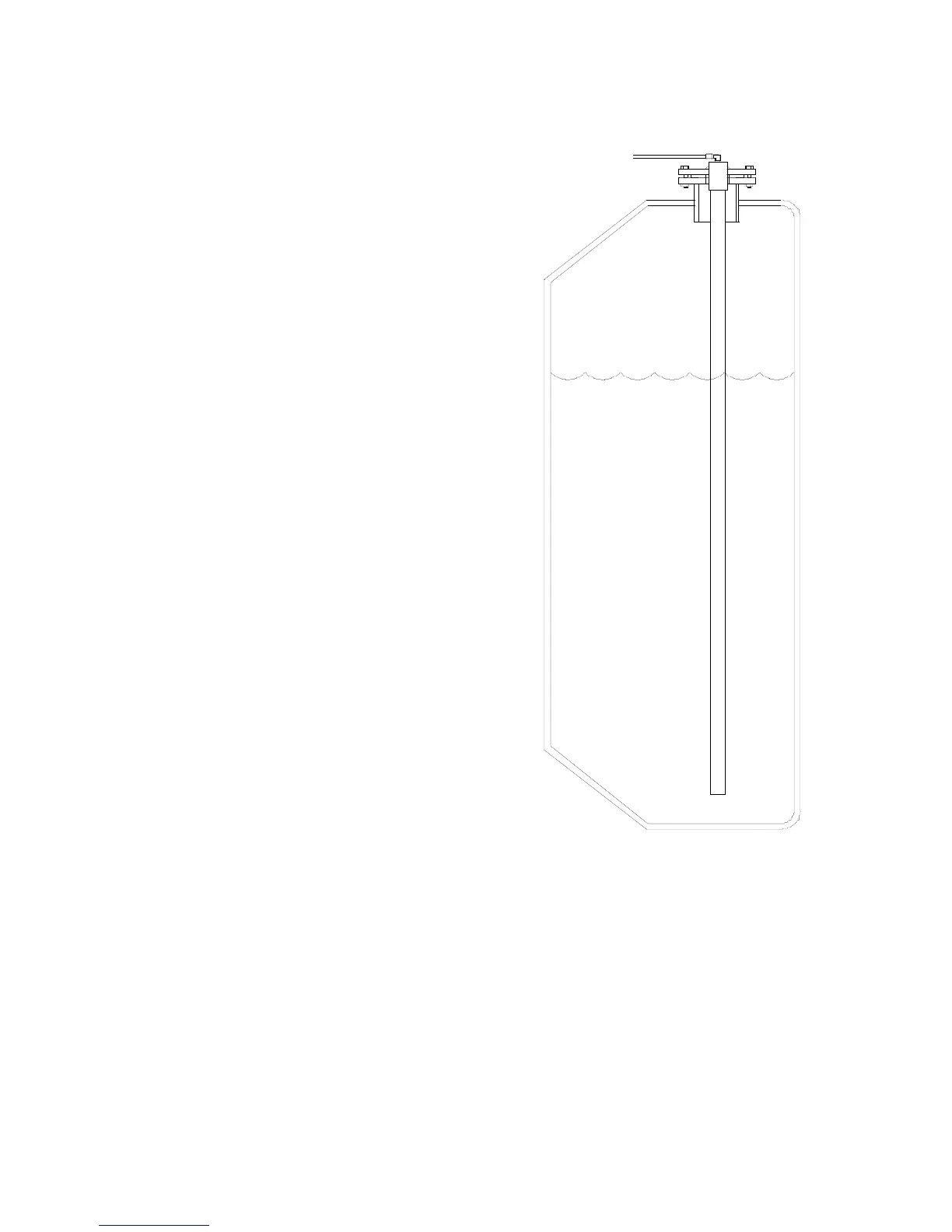

In tanks where there is agitation, mechanical

properties along with the diameter of the

bubbler pipe need to be considered. Agitation

and significant sloshing of the liquid will require

more mechanical strength in both the pipe and

mounting system. This is an especially

important factor to consider, when the pipe is

mounted to a flange at the top of the tank and

has no other support. Figure 5 shows a typical

flange mount installation. Note that the pipe is

only supported at the top.

Materials

It is important that the bubbler pipe be made of

materials compatible with the liquid to be

measured. Deterioration of the bubbler pipe will

result in measurement errors and eventually

failure of the sensing system.

For example if the LevelCom 100 is gauging a

ship’s ballast tank and will be exposed to salt

water, steel pipe will eventually corrode from constant exposure to salt water and should not

be used. In tanks containing acids or corrosives plastic pipe may be a better option.

It is always important to consider the strength of the materials used for the bubbler pipe.

When using plastic pipe, for instance, it would be better to use thick wall pipe (Schedule 40

or 80 for example) rather than thin wall pipe for mechanical strength.

Figure 5 Flange Mounting Example

TUBING TO

LevelCom

Loading...

Loading...