Page 20

©2013 Technical Marine Service, Inc. LC-100 V2.97

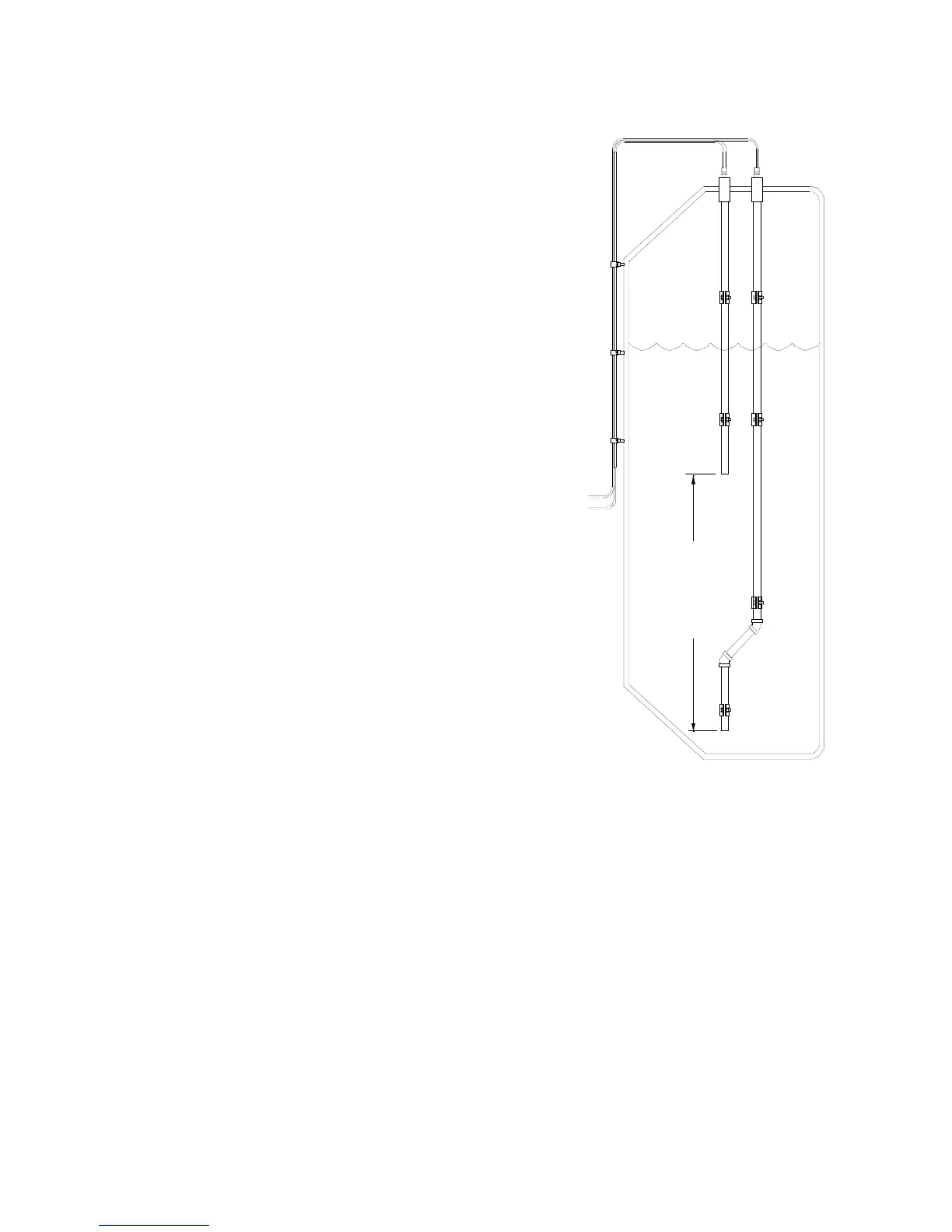

Side Mount Installation, is sometimes required

when tank top access is not possible. Figure

6 shows this kind of installation. If there is a

flange and cover on the side of the tank, the

bubbler pipe could enter through this flange.

This may simplify the mounting of the bubbler

pipe in the tank.

For this type of installation, it is important that

the interconnecting tubing run upward to a

point above the top of the tank and then back

down to the LevelCom 100. This is necessary

to prevent liquid from siphoning to the

interconnecting tubing system if the LevelCom

100 must be removed from the system for

service.

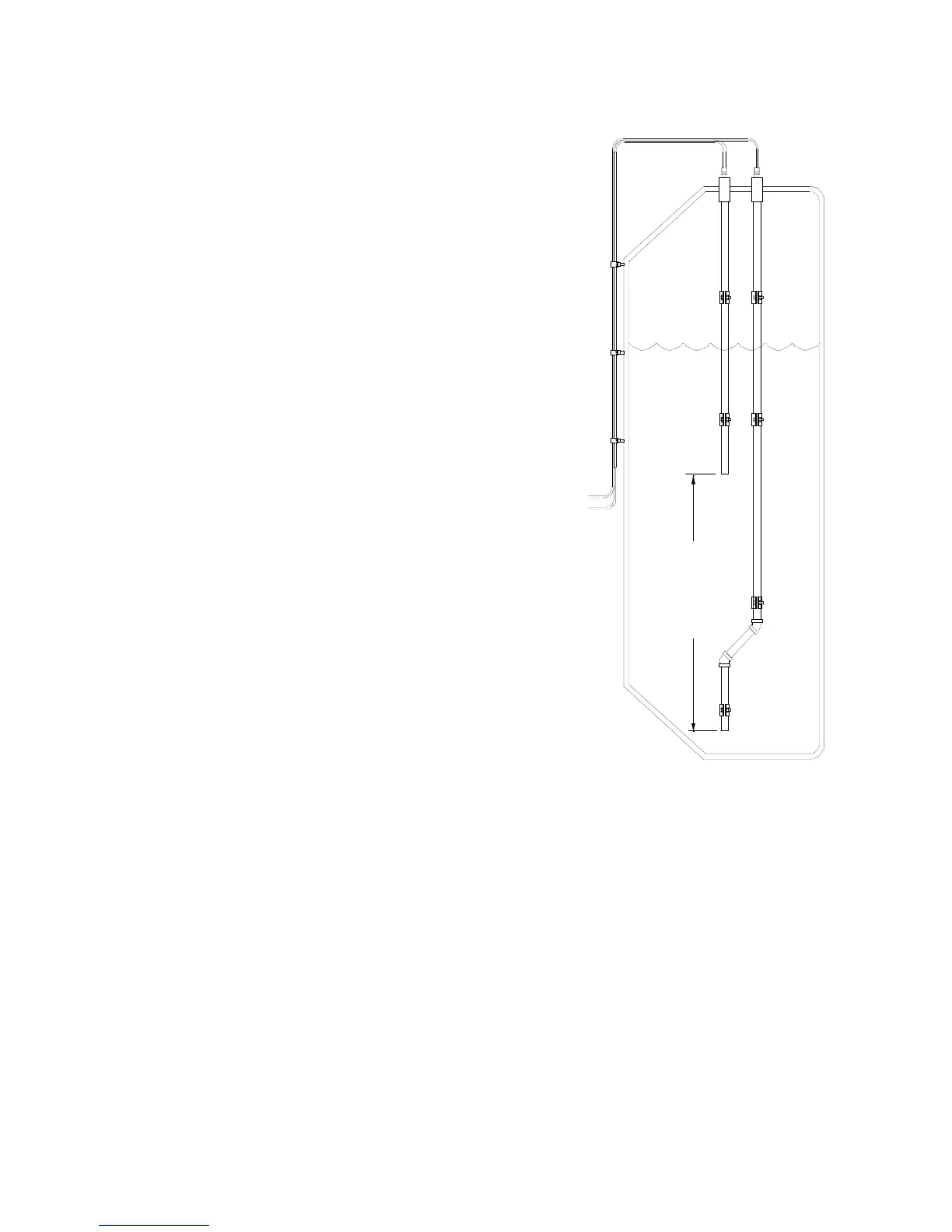

Specific Gravity

A LevelCom 100 with the automatic specific

gravity option needs a second bubbler pipe in

the tank. The second pipe should be shorter

than the main bubbler pipe. Figure 7 shows a

typical specific gravity installation. The ends

of the two bubbler pipes need to be a known

vertical distance apart. The two bubbler pipes

should also be mounted so that the bottom

ends of the pipes are in the same vertical line.

This will minimize any errors caused by side to

side trim changes in the ship.

With the specific gravity option, the LevelCom

100 will take separate measurements on each

of the two bubbler pipes. Using the known

distance between the ends of the bubbler pipes, the two pressure readings can be used to

calculate the specific gravity of the fluid. This kind of installation is useful where the specific

gravity of the fluid in the tank is variable.

Figure 7 Specific Gravity Example

TUBING TO

LevelCom

S

.

G

.

D

I

S

T

A

N

C

E

Loading...

Loading...