Page 17

©2013 Technical Marine Service, Inc. LC-100 V2.97

Bubbler Pipes

General

Bubbler pipes are mounted inside the tanks,

and are the part of the sensing system in direct

contact with the measured liquid. When a

LevelCom 100 is replacing an older bubbler

gauge, the bubbler pipes and interconnecting

tubing need to be checked for leaks and plugs.

Otherwise there should be no concerns about

mounting and design of the sensing system.

NOTE:

The bubbler pipe is the key component in a

bubbler type level sensing system. Mounting

the bubbler pipe in the tank is critical to the

long term operation of the level measuring

system.

In new installations it is important that the

bubbler system is correctly designed and

installed. This section will describe various

bubbler pipe designs and other factors that

must be considered to arrive at a system that

operates correctly and provides reliable long

lasting service.

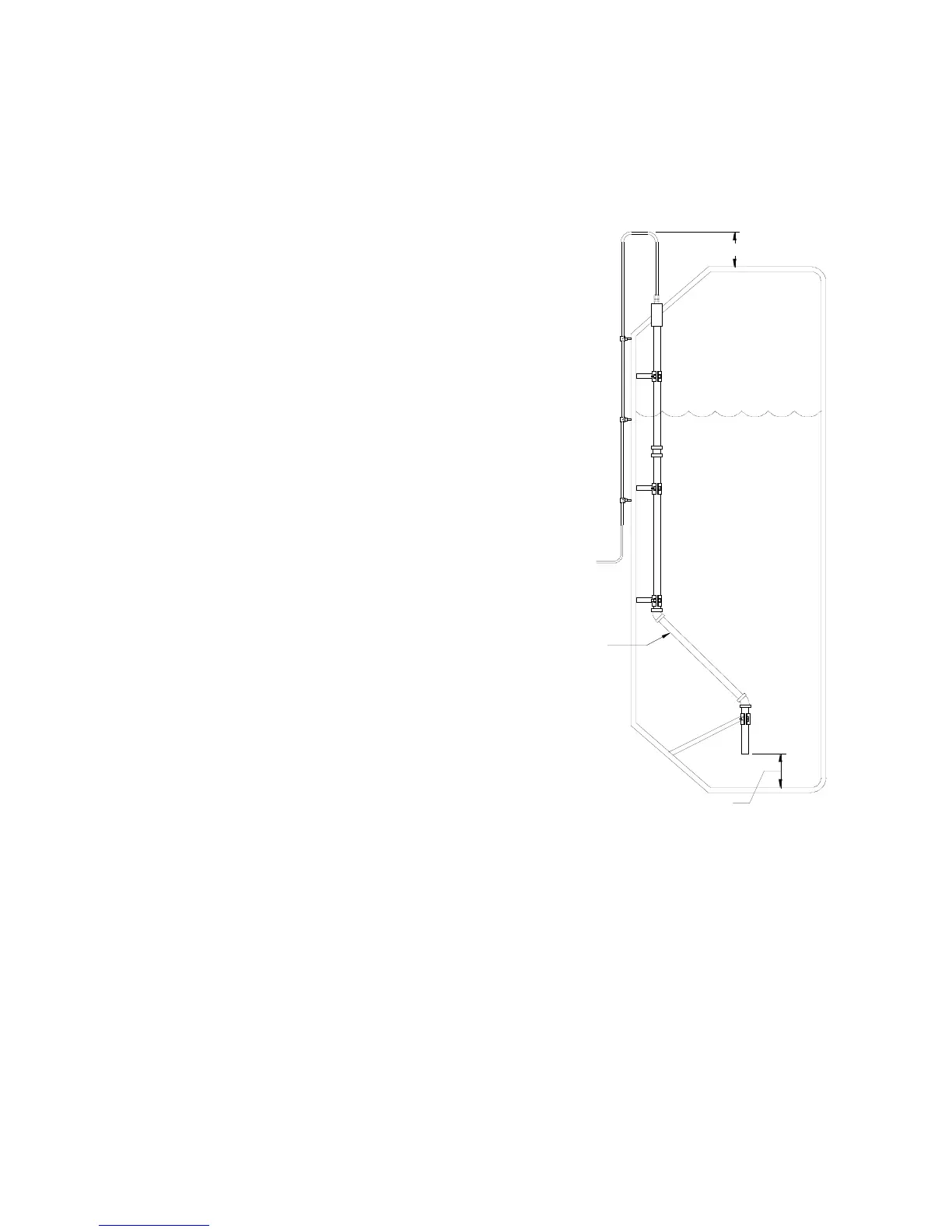

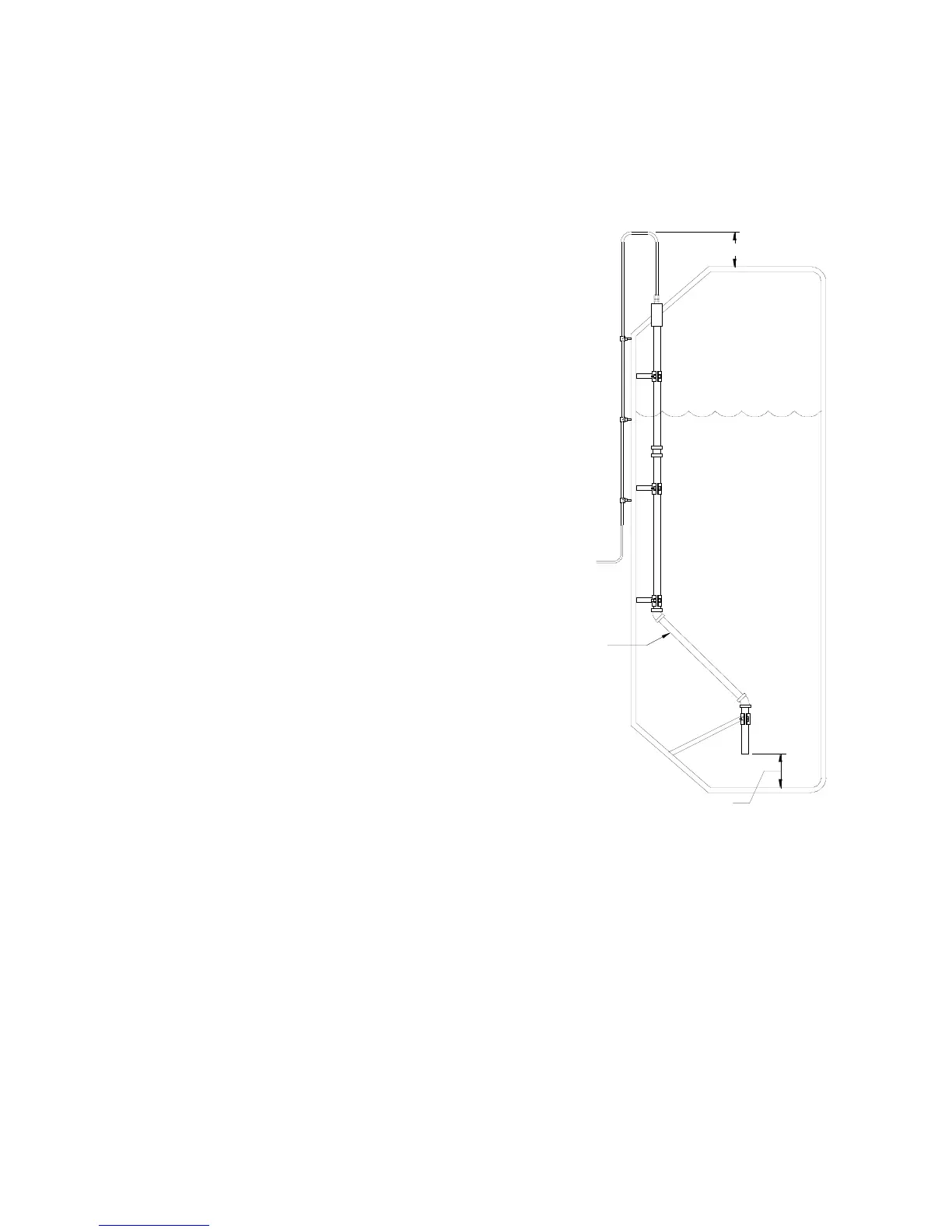

Figure 4 shows a typical in tank installation.

Note that the bubbler pipe is well supported

and is installed to gauge the deepest part of

the tank. The interconnecting tubing is run to a

point higher than the maximum height of the

tank to prevent siphoning of fluids in case the

tubing is disconnected from the LevelCom 100.

Size considerations

The diameter of the bubbler pipe will have effects on the system performance. The minimum

diameter for a bubbler pipe is ½ inch. The size range for bubbler pipes is typically from ½ to

1-1/2 inches. A smaller diameter bubbler pipe is more sensitive to leaks in the sensing

system and may be prone to plugging. Leaks will always cause errors in reading. The

smaller the bubbler pipe, the greater the errors due to leaks.

TUBING TO

LevelCom

1/2" - 1 1/2" PIPE

ANTI-SIPHON

BUBBLER TO BOTTOM

Figure 4 Typical Bubbler Pipe

Loading...

Loading...