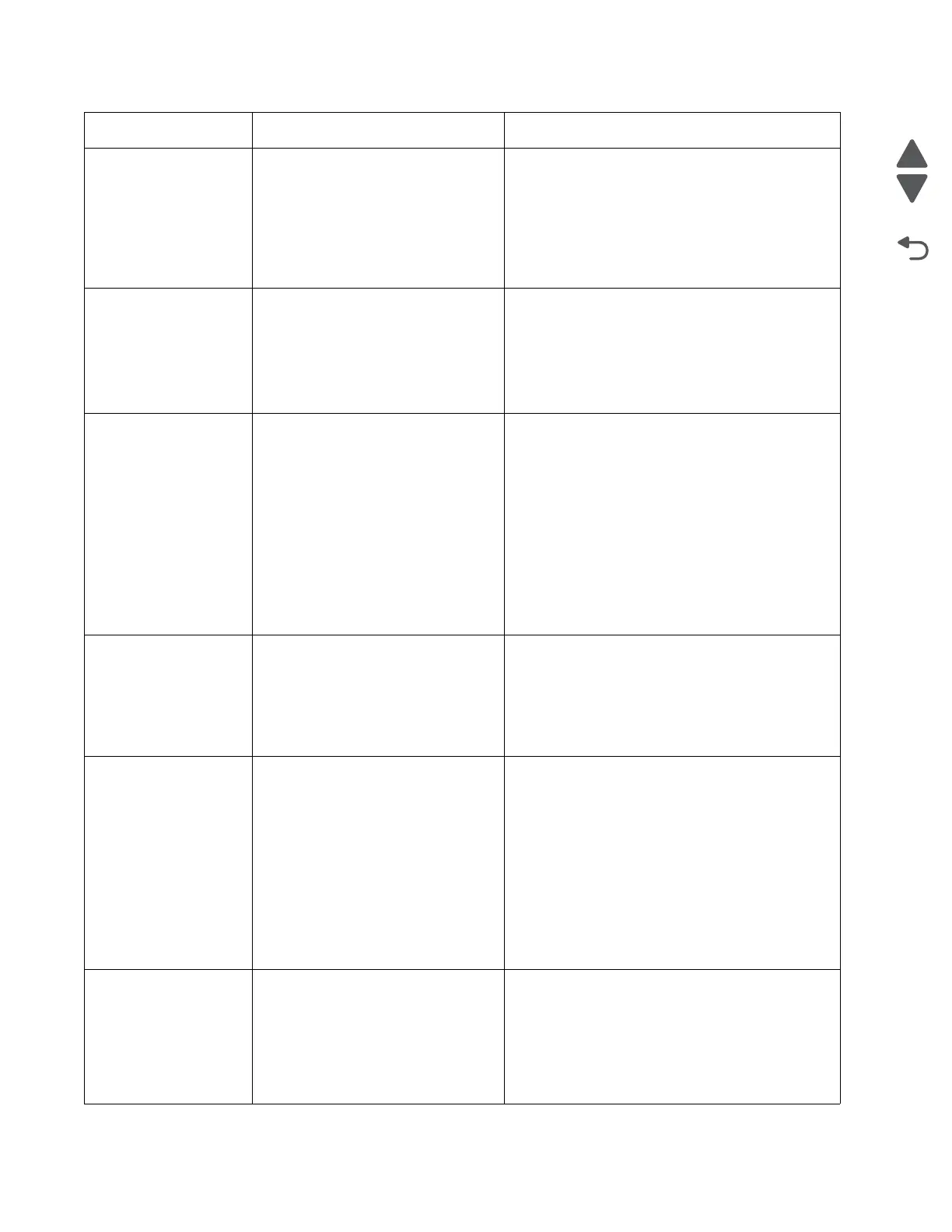

2-26 Service Manual

7526

242.05 Tray 2 picked, but page failed to reach

the option sensor in time.

Possible causes:

• Incorrect media setting

• Incorrect paper loading

• Incorrect media restraint setting

• Faulty paper pick mechanism

• Ensure proper media is set for the type of paper

used in tray 2.

• Fan media, and stack flat in tray 2.

• Properly set the media restraints in tray 2.

• Check the pick tires in tray 2 and replace if worn.

• If the previous actions do not fix the problem, go

to “242.05—Paper Jam service check” on

page 2-74.

242.10 Tray 2 page exits pass thru made

early.

Possible causes:

• Defective pass thru sensor

• Faulty cable in the connector

OPT1 on system board.

• Ensure the proper media is set for the type of

paper used in tray 2.

• Check for anything in the paper path that might

cause the paper to jam.

• The exits pass thru sensor may not be

functioning properly. Go to “242.10—Paper

Jam service check” on page 2-75.

242.11 Tray 2 sensor never broke.

Possible causes:

• Incorrect tray 2 media setting

• Incorrect Tray 2 paper loading

• Incorrect media restraint setting

• Paper tray failure

• Aligner failure

• Transport belt module failure

• Loading card stock from the

special media tray above the fill

line.

• High humidity (replace paper)

• Ensure the proper media is set for the type of

paper used in tray 2.

• Fan media, and then stack flat in tray 2.

• Properly set the media restraints in tray 2.

• If the problem persists, go to “242.03, 242.11—

Paper Jam service check” on page 2-73.

242.17 Tray 2 detected a jam from idle.

Possible causes:

• Paper jam leaving page over

sensor

• Defective input sensor

• Faulty system board

• Clear away anything in the paper path that might

cause the paper to jam.

• If clearing a paper jam does not fix the problem,

go to “242.17—Paper Jam service check” on

page 2-76.

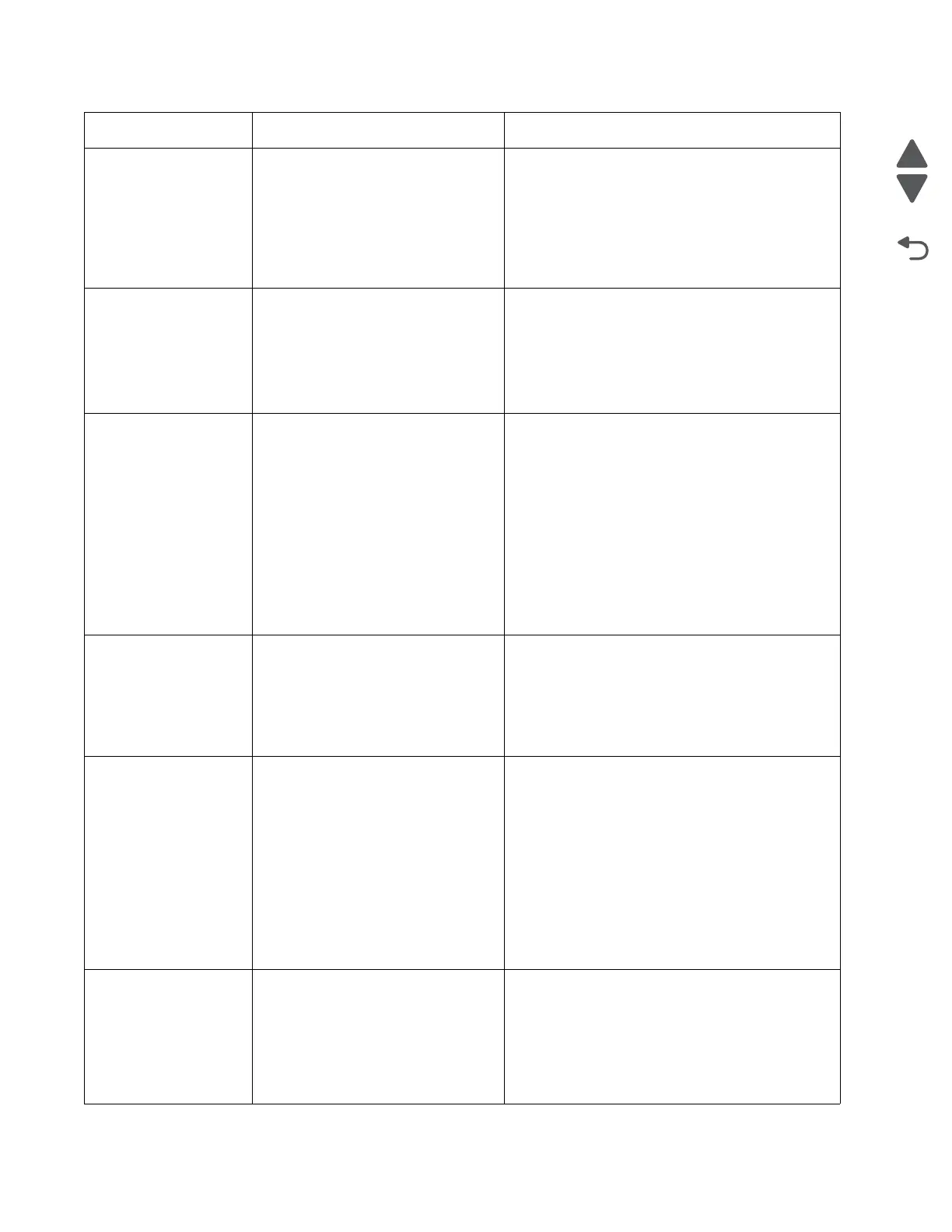

242.26 While feeding from tray 2, the pass

thru sensor is not made.

Possible causes:

• Incorrect paper loading for lower

tray

• Incorrect media restraint setting

for lower tray

• Paper tray 2 assembly failure

• Lower tray 3 assembly failure

• Clear away anything in the paper path that might

cause the paper to jam.

• Ensure the proper media is set for the type of

paper used in the lower tray.

• Fan the media, and then stack flat in the lower

tray.

• Properly set the media restraints in the lower

tray.

• Check the pick tires in the lower tray, and then

replace if worn.

• If clearing a paper jam does not fix the problem,

go to “242.26—Paper Jam service check” on

page 2-77.

242.27 While feeding from a lower tray, the

pass thru sensor did not break.

Possible causes:

• Paper tray 2 assembly failure

(feed thru roller)

• Aligner failure

• Transport belt motor failure

• Clear away anything in the paper path that might

cause the paper to jam.

• Reseat option tray 2.

• If the problem persists, go to “242.27—Paper

Jam service check” on page 2-77.

Error code Description Action

Loading...

Loading...