MAINTENANCE/SERVICE

Traction Drive: Neutral Set-Up Procedure

This procedure should be performed only after

the

nine

preceding checks

and

adjustments

have

failed

to

so

lve

the

neutral lock/stee

ring

problem

.

This procedure will eliminate mach

in

e movement

in

neutral and will improve neutral

lo

cking ability.

A

A

CAUTION:

Use

jack-stands with a

minimum capacity

of

3 tons (2720

kg)

to

provide

adequate

support

for

machine.

DANGER: Never attempt neutral

set-up procedure

without

raising

front

wheels

off

the

ground

so

they

are free 10

tum

. Failure to raise

front

wheels

will

result in machine runaway,

causing severe personal injury

or

death.

1.

Detach header and remove hay conditioner

formi

ng

shields from under tractor.

2.

Raise front

of

machine high enough to allow

both wheels to turn freely and support with

jack-stands.

See "Jacking Procedure" under

Wheel & Tire Maintenance in this section.

3.

Start engine and idle at approximately

12

00-

1500

RPM

.

4. Set controls as follows:

Ground speed lever in neutral.

Steering wheel locked.

• Park brake disengaged.

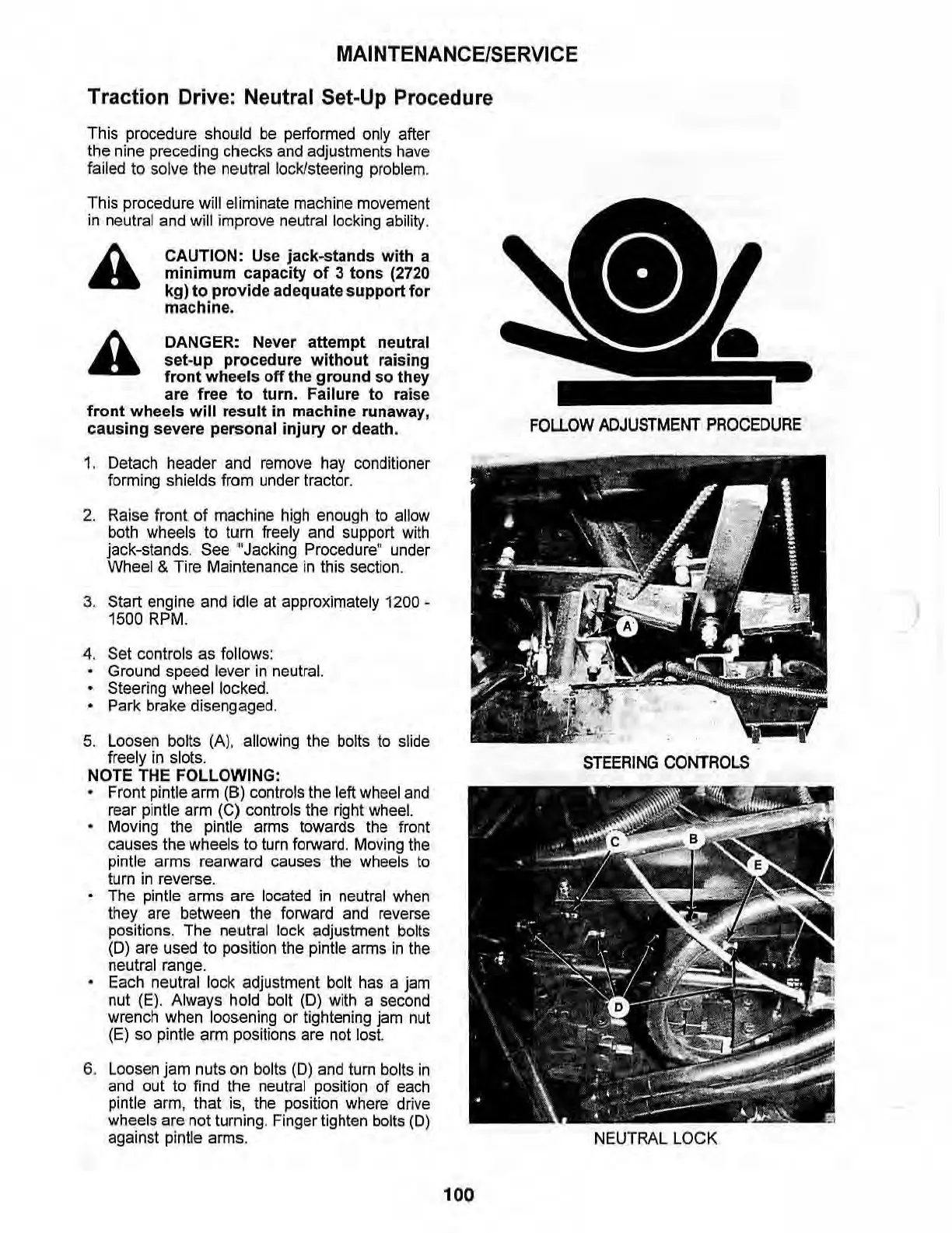

5.

Loosen bolts (A), allowing the bolts to slide

freely in slots.

NOTE

THE

FOLLOWING:

Front pintle a

rm

(8)

controls the left wheel and

rear pintle arm (C) controls the right

wheel.

Moving the pintle arms towards the front

causes the wheels to turn forward. Moving the

pintle arms rearward causes the wheels to

turn in reverse.

The pintle arms are located in neutral when

they are between the forward and reverse

positions. The neutral lock adjustment bolts

(D) are used to position the pintle arms

in

the

neutral range.

Each neutral lock adjustment bolt has a jam

nut (E

).

Always hold bolt

(0)

with a second

wrench when looseni

ng

or tightening jam nut

(

E)

so pintle arm positions are not lost.

6.

Loosen jam nuts on bolts (D) and turn bolts

in

and out to find the neutral position of each

pintle arm, that is, the position where drive

wheels are not turning. Finger tighten

bolts (D)

against pintle arms.

100

FOLLOW

ADJUSTMENT

PROCEDURE

STEERING

CONTROLS

NEUTRAL

LOCK

)

Loading...

Loading...