GROVE 7-37

CD3340B/YB4411 TRANSMISSION AND TORQUE CONVERTER

Published 04/07/2015 Control # 569-00

27. Unscrew eleven bolts (35, Figure 7-34) and remove

flywheel housing (36). It may be necessary to tap the

housing with a soft hammer to release the flywheel from

dowels (37).

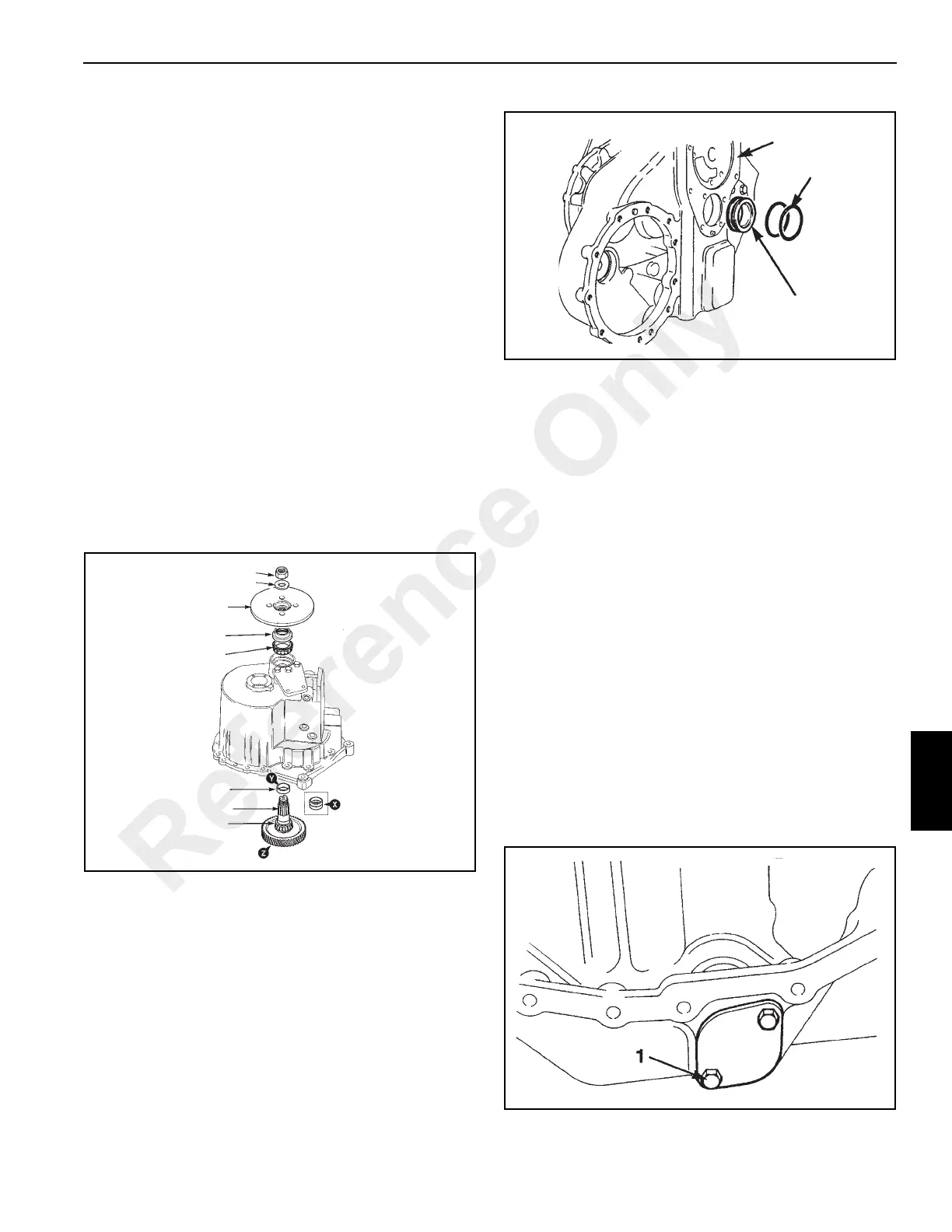

28. Mark the position of the brake disc (38, Figure 7-35) on

the spline output shaft (41). While holding the disc,

unscrew output shaft nut (40) and remove with washer

(39). Support output shaft (41) from beneath and lift off

the brake disc. Remove the output shaft assembly.

NOTE: Due to ratio options some transmissions feature a

larger output gear (Z). When removing the output

shaft (41) the gear may hit the gearbox housing,

preventing removal. For shaft removal procedures

see Output Shaft Removal - Larger Diameter Gear.

29. Pry out oil seal (42) and discard.

30. Remove outer taper bearing (43).

31. Remove spacer (44) and retain for assembly, if type Y.

NOTE: If spacer (44) is the collapsible type (X,

Figure 7-35), discard it. It is recommended

replacing it with a solid spacer. See Assembly step.

32. Using a suitable puller, remove inner bearing (45).

33. Remove and discard two O-rings (51, Figure 7-36) from

casing (49).

34. Carefully, from inside casing (49), tap out spacer (50).

35. Finally, after disassembly, make sure casings and parts

have been thoroughly cleaned using suitable solvents

before starting the assembly procedures. Be sure the

suction strainer is thoroughly cleaned and dried before

assembly.

Assembly

NOTE: Before starting the assembly of the transmission,

make sure that all casings and components,

including the suction strainer, have been

thoroughly cleaned with a suitable solvent.

When assembling, coat bearings with a Lithium Base, E.P.

No. 2 bearing grease. Replace all O-rings, seals and

gaskets.

Remember that dirt in the transmission system will cause

damage to the transmission and its associated parts,

particularly the transmission pump.

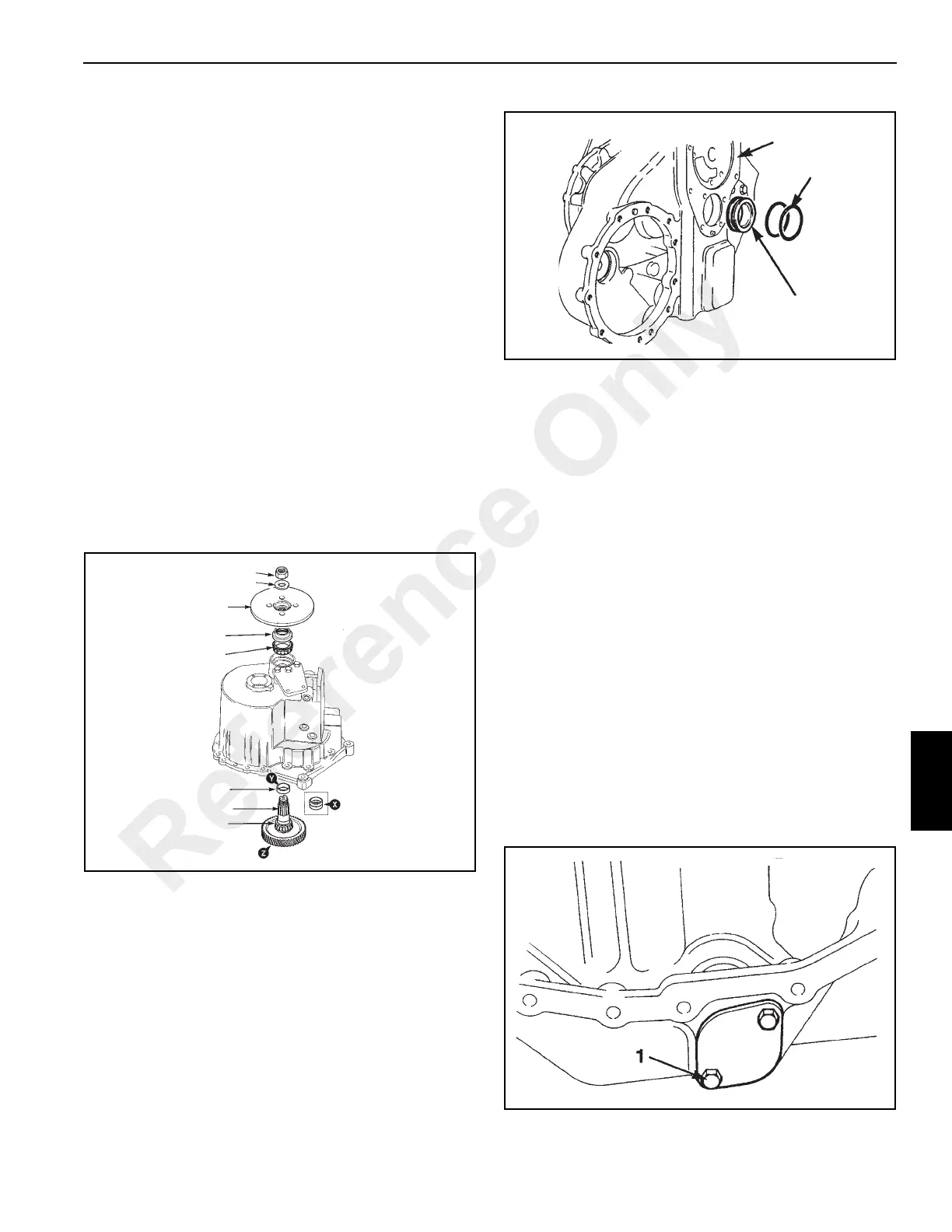

1. Using a new gasket, install the suction strainer. Apply

Loctite 243 to bolts (1, Figure 7-37) and tighten to a

torque of 10 Nm (7 lb-ft).

If removed, install bearing cups into gear casing.

NOTE: If the transmission has not been thoroughly

cleaned during overhaul, any particles below 200

microns (0.2 mm) can pass through the existing

suction strainer and into the transmission pump

before being caught in the pressure filter.

It is recommended that a special 75 micron (0.075

mm) service suction filter be temporarily installed.

FIGURE 7-35

a0811

40

39

38

42

43

45

41

44

Reference Only

Loading...

Loading...