TRANSMISSION AND TORQUE CONVERTER CD3340B/YB4411

7-42

Published 04/07/2015 Control # 569-00

d. Calculate the required thickness of shims to give the

correct end play, which should be 0.03 - 0.08 mm

(0.001 - 0.003 in).

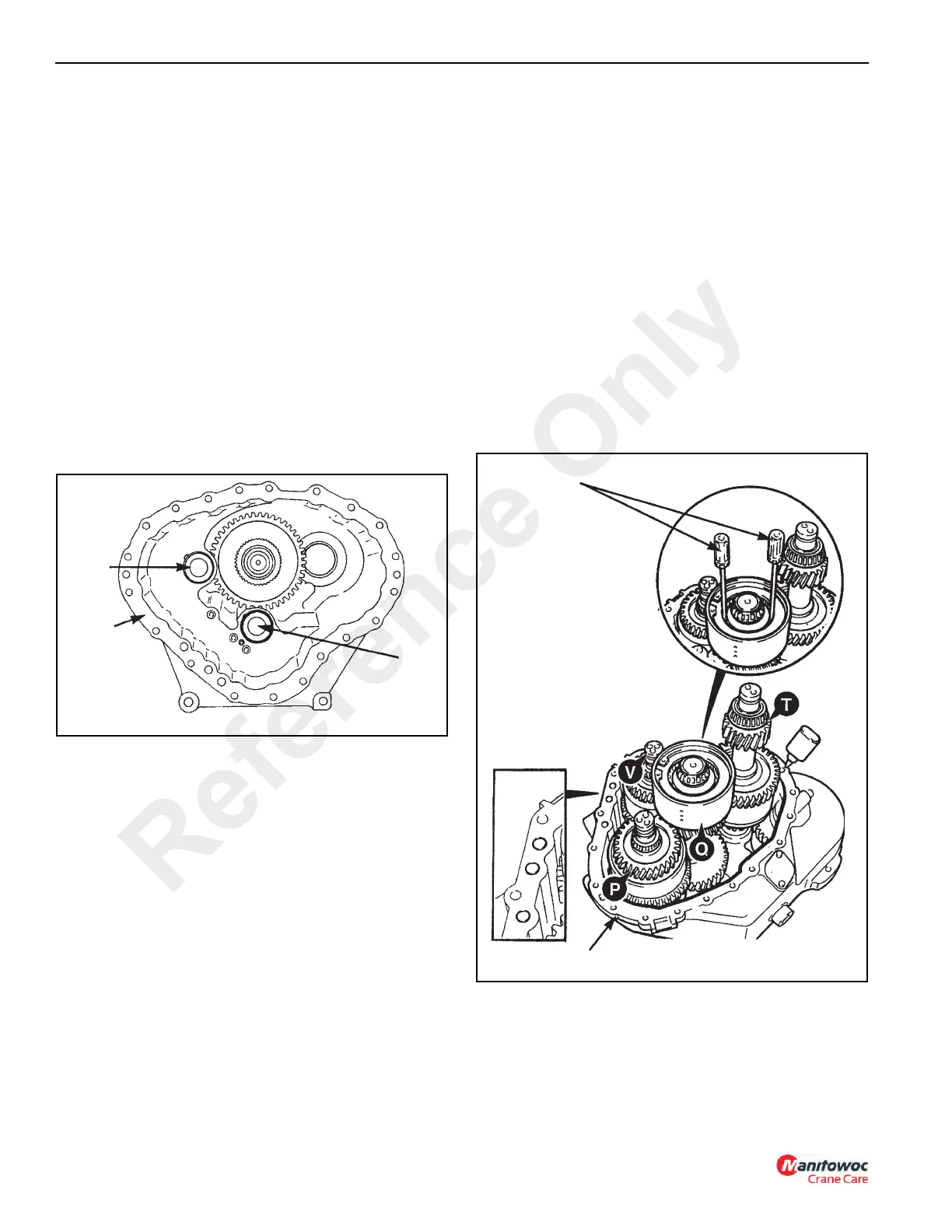

12. Separate the two casing halves and add or subtract

shims (34, Figure 7-49) installed beneath the outer

races in the rear (output) case 32 to correct input and

forward shaft end float. Repeat steps 10 and 11, or 12

and 13 to recheck the end play.

NOTE: Production transmissions have the shims installed

in the front case; however when servicing the

transmission, it is permissible to install shims (34)

in the rear case as shown.

When correct end play has been achieved, remove the input

and reverser clutch shafts and install piston ring seals 46

removed in step 6.

NOTE: Do not reinstall the input and forward clutch shafts

at this time. They must be installed with the other

shafts into the transmission - see steps 13 to 15.

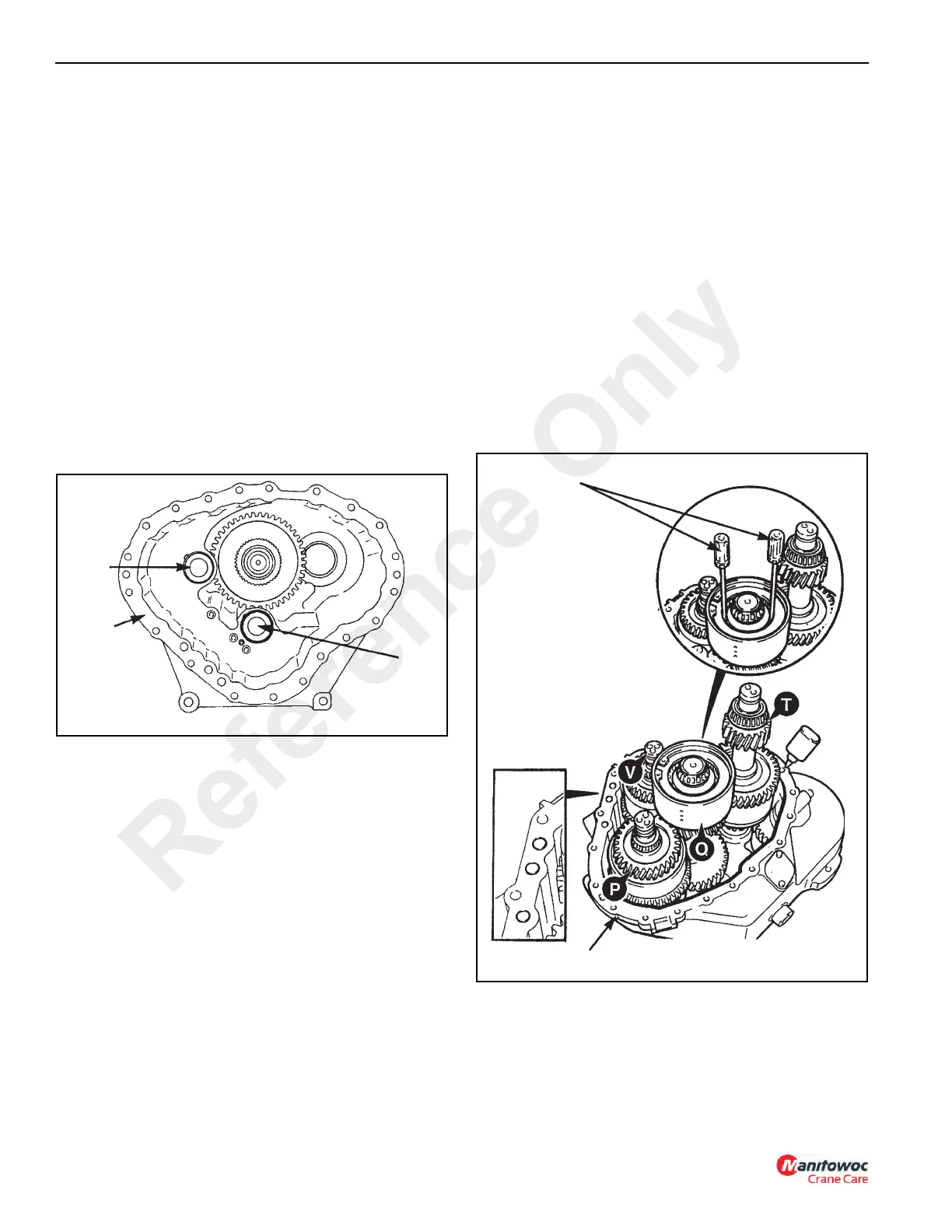

13. Install input clutch (V, Figure 7-50) and main shaft (Q)

simultaneously into the front case as shown. Before

installing make sure that all the piston ring seals have

been replaced with new seals and lightly greased and

fully seated in their grooves. (See PTFE Piston Ring

Seal Installation Procedure). Also ensure that both the

input clutch and main shaft taper roller bearings have

been coated with a Lithium Base, E.P. No. 2 bearing

grease.

a. Install all remaining bearing cups. Install main shaft

end spacer 50. DO NOT install O-rings at this point.

See NOTE below.

End spacers have extraction holes to assist

removal. Install the spacer with the extraction holes

facing towards you.

NOTE: This is a preparatory step for setting the main shaft

end play. At a later point it will be necessary to

remove the end spacer so that shims can be

installed to set the end play. If the O-rings are left

on at this point, the spacer will be difficult to

remove. New O-rings are installed after the correct

main shaft end play has been set.

b. Install the end play setting tool P/N 1900449

(Figure 7-15) over the main shaft end bearing and

spacer. Tighten the bolts to 52 Nm (42 lb-ft).

14. This step requires the help of an assistant. Have the

assistant SLIGHTLY raise and tilt the input clutch V and

mainshaft Q. While the assistant is holding the two units,

install forward clutch (P).

15. Coat the layshaft taper roller bearings with a Lithium

Base, E.P. No. 2 bearing grease and install the layshaft

assembly (T) into the front case.

The arrangement of the clutch assemblies should now

be as shown in Figure 7-50. Make sure all bearings are

fully seated, and that the relevant gears have meshed

correctly.

16. Using two small rods or screwdrivers (A, Figure 7-50),

align all the friction/counter plates of the main shaft

clutch.

17. Install three new O-rings (33) in the front case (49). Coat

the O-rings with grease to hold in position.

Reference Only

Loading...

Loading...