GROVE 7-43

CD3340B/YB4411 TRANSMISSION AND TORQUE CONVERTER

Published 04/07/2015 Control # 569-00

NOTE: Do not apply an excessive amount of Loctite 574

around the O-rings. Too much can dislodge the

O-rings.

18. Apply Loctite 574 to the front case mating face. Prior to

installing the rear case, ensure that all bearings have

been coated with a Lithium Base, E.P. No. 2 bearing

grease. Ensure that all piston ring seals are fully seated

and have been coated with grease.

19. Make sure all the friction/counter plates in the main shaft

clutch are aligned (see Step 16). Carefully lower the rear

(output) case into position, taking care to align the output

gear splines with the main shaft clutch friction/counter

plates. If the casing does not drop down onto the

dowels, gently rotate the disc back and forth to center

the plates. Apply Loctite 243 to bolts and tighten to a

torque of 56 Nm (42 lb-ft).

NOTE: To aid in assembly of the rear case, use tool P/N

1903746 (Figure 7-19) and an airline to clamp the

pack and hold it position when lowering rear case

into position.

Do not use the retaining bolts or external force to

close the casing joint or the plates will be damaged.

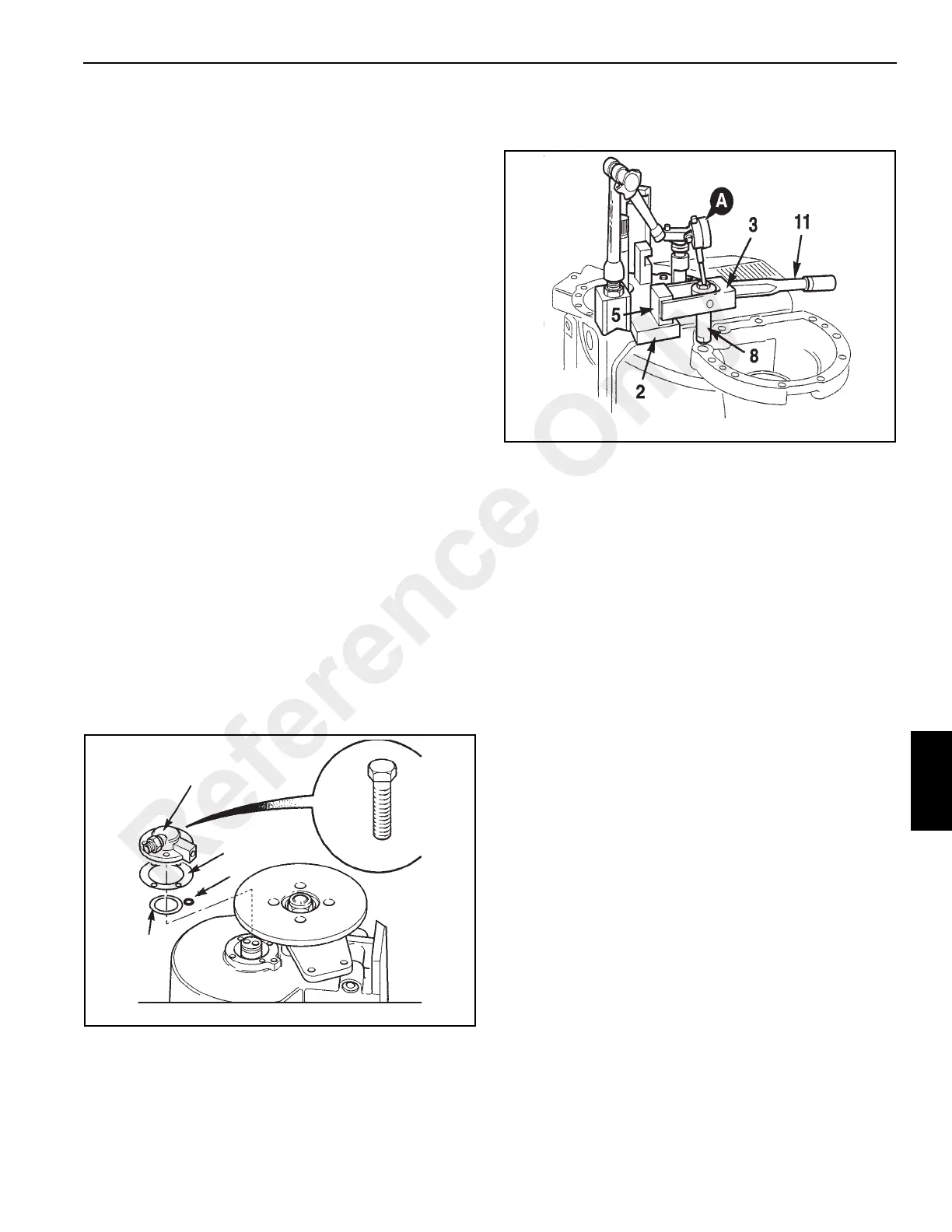

20. Using a new gasket (28, Figure 7-51), temporarily install

the layshaft end cap (27) and shims (29). Tighten

retaining bolts (26) to a torque of 56 Nm (42 lb-ft).

NOTE: Installing the layshaft end cap at this stage is a

temporary arrangement to enable the

measurement of the layshaft end play. Do not apply

Loctite 243 to the retaining bolts at this time.

NOTE: Take care not to damage the gasket because it

must be used during final assembly.

21. Measure the end play for the layshaft using the end play

checking kit.

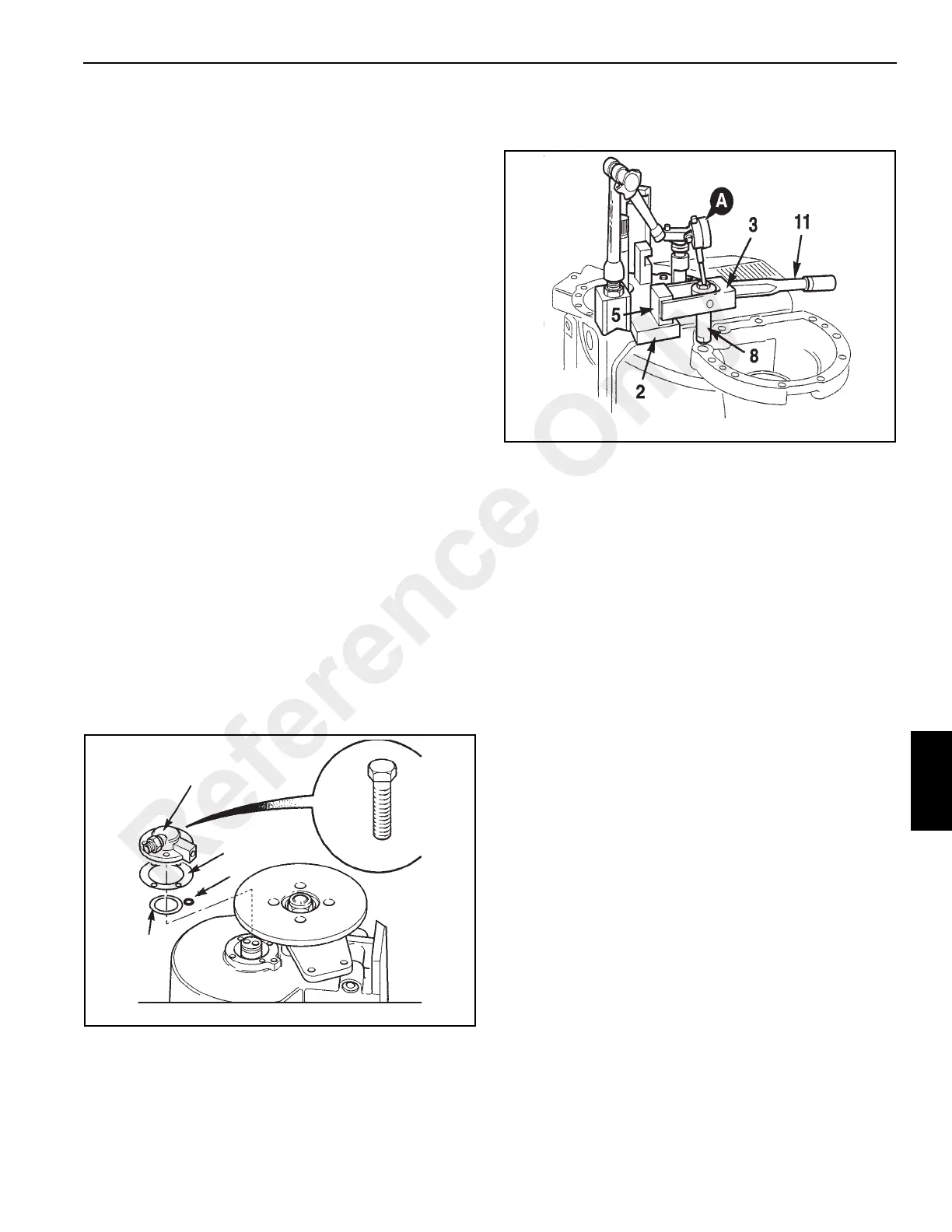

NOTE: Numbers in Figure 7-52 correspond with numbers

in Figure 7-24.

a. Place the transmission on a work bench with the

input side up so that the drive shaft mounted flange

can be turned.

b. Secure base plate 2 on the face of the casing using

existing tapped holes for the mounting bolts. Tighten

the bolts to a torque of 56 Nm (42 lb-ft).

c. Select adapter 8 from the kit (Figure 7-24) and

screw it into the tapped hole in the layshaft.

d. Locate yoke 3 and wrench 11 into adapter 8 and

pillar 5. Set the wrench to 35 Nm (26 lb-ft).

e. Using a magnetic block, mount a dial test indicator

(DTI) A with the probe on the head of adapter 8 and

adjust to zero.

f. While rotating the layshaft back and forth using the

flange on output shaft to seat the bearings, lift and

depress wrench 11 and note the reading on the DTI.

g. Remove wrench 11 and adapter 8 from the layshaft

assembly.

h. Calculate the required thickness of shims to give

correct end play, which should be 0.03 - 0.08 mm

(0.001 - 0.003 in). The end shaft play should be set

as near as possible to the minimum tolerance.

22. If the end play checking kit is not available, use the

following procedure.

Set up a dial test indicator (DTI) as shown in Figure 7-55

on a suitable M10 bolt and measure layshaft end play,

which should be 0.03 - 0.08 mm (0.001 - 0.003 in).

Rotate the shaft (using the flange) while measuring to

seat the bearing fully.

NOTE: When measuring the end play, rotate the flange on

2WD transmissions.

FIGURE 7-51

a0822

27

26

28

30

29

Reference Only

Loading...

Loading...